Injection device for casting device and casting method

A technology of injection device and injection port, which is applied in the field of injection devices, can solve the problems of reduced suction area, inappropriateness, and increased adjustment time, and achieve the effects of reducing replacement time, preventing advanced melt, and expanding versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

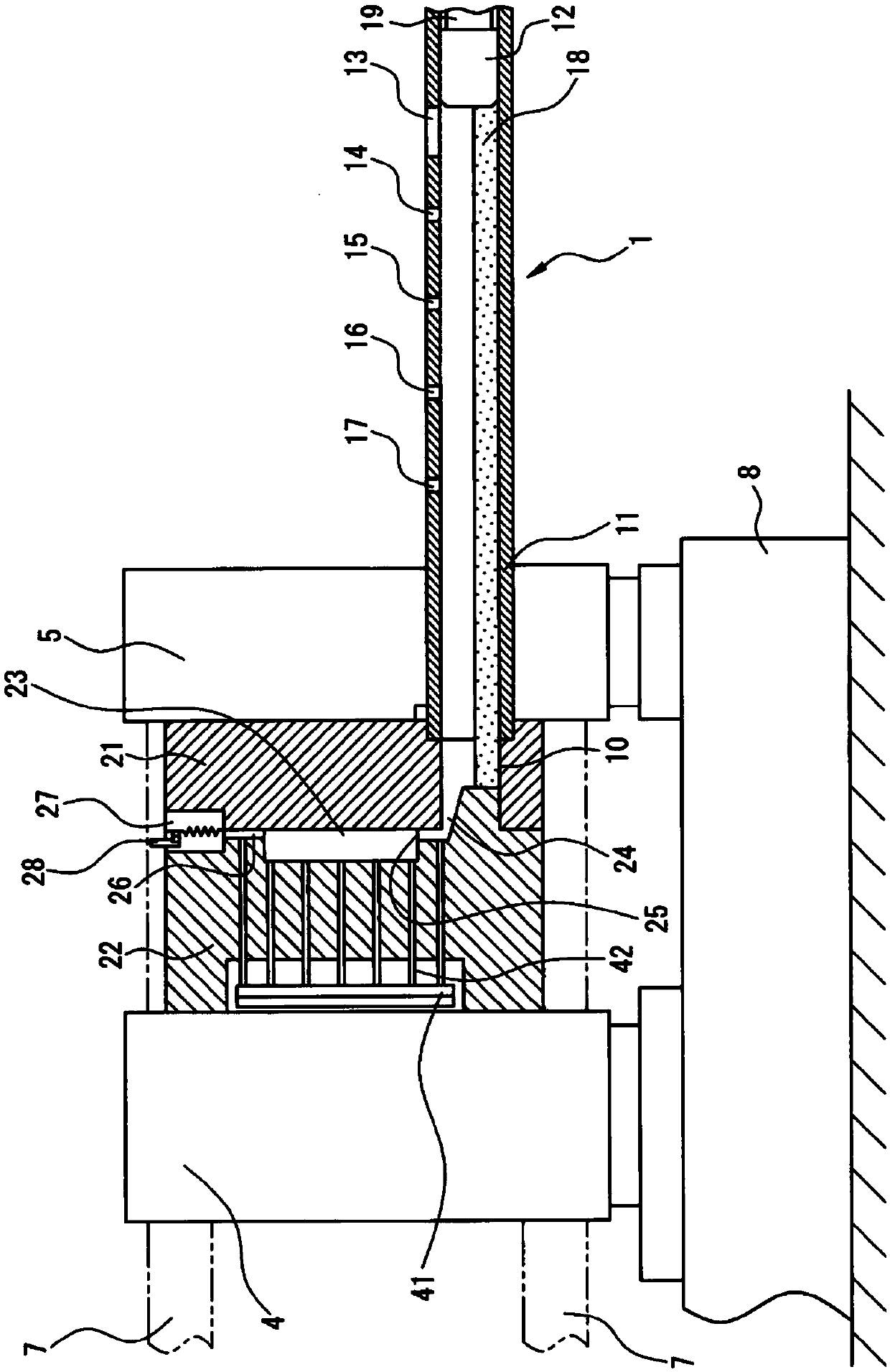

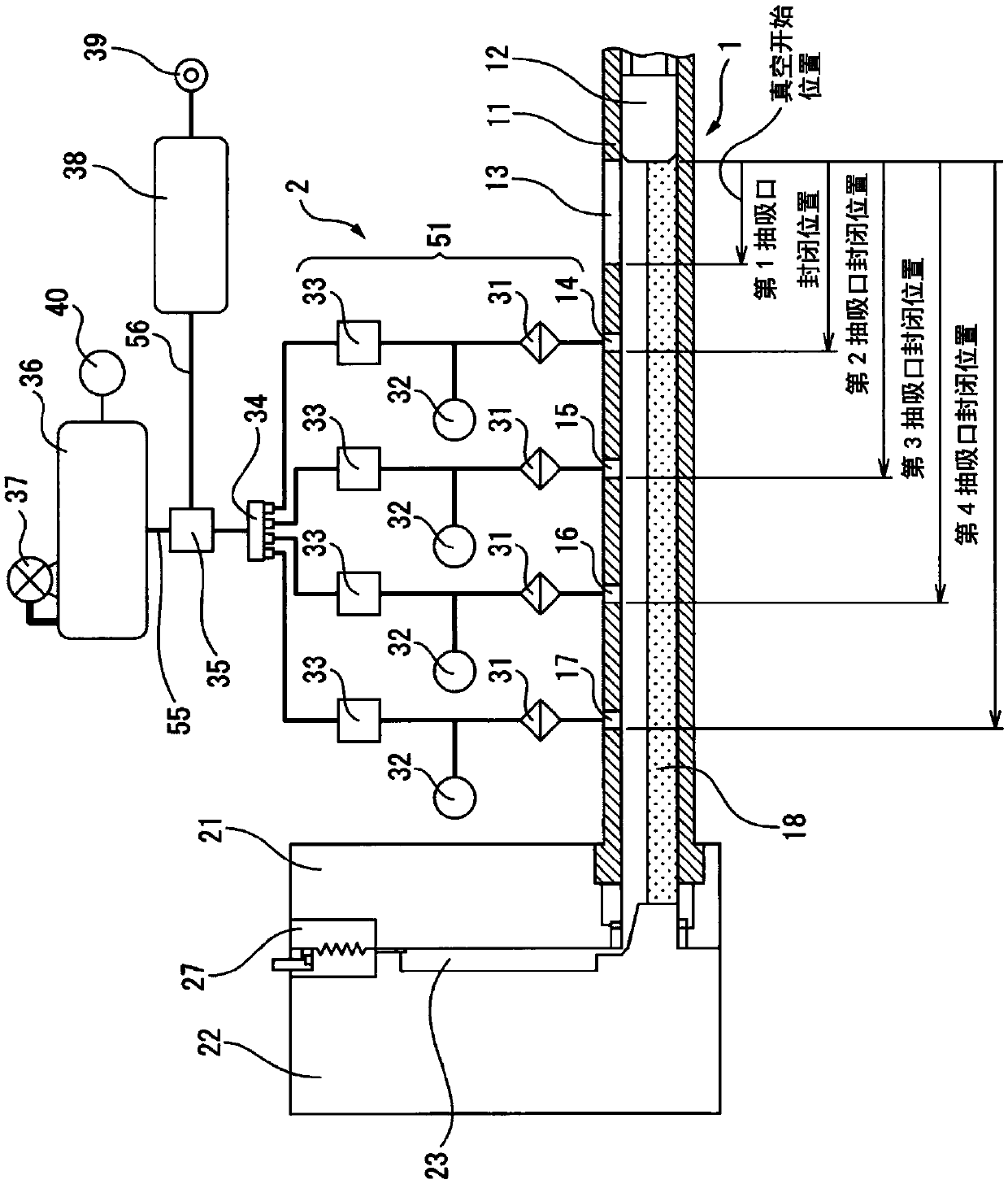

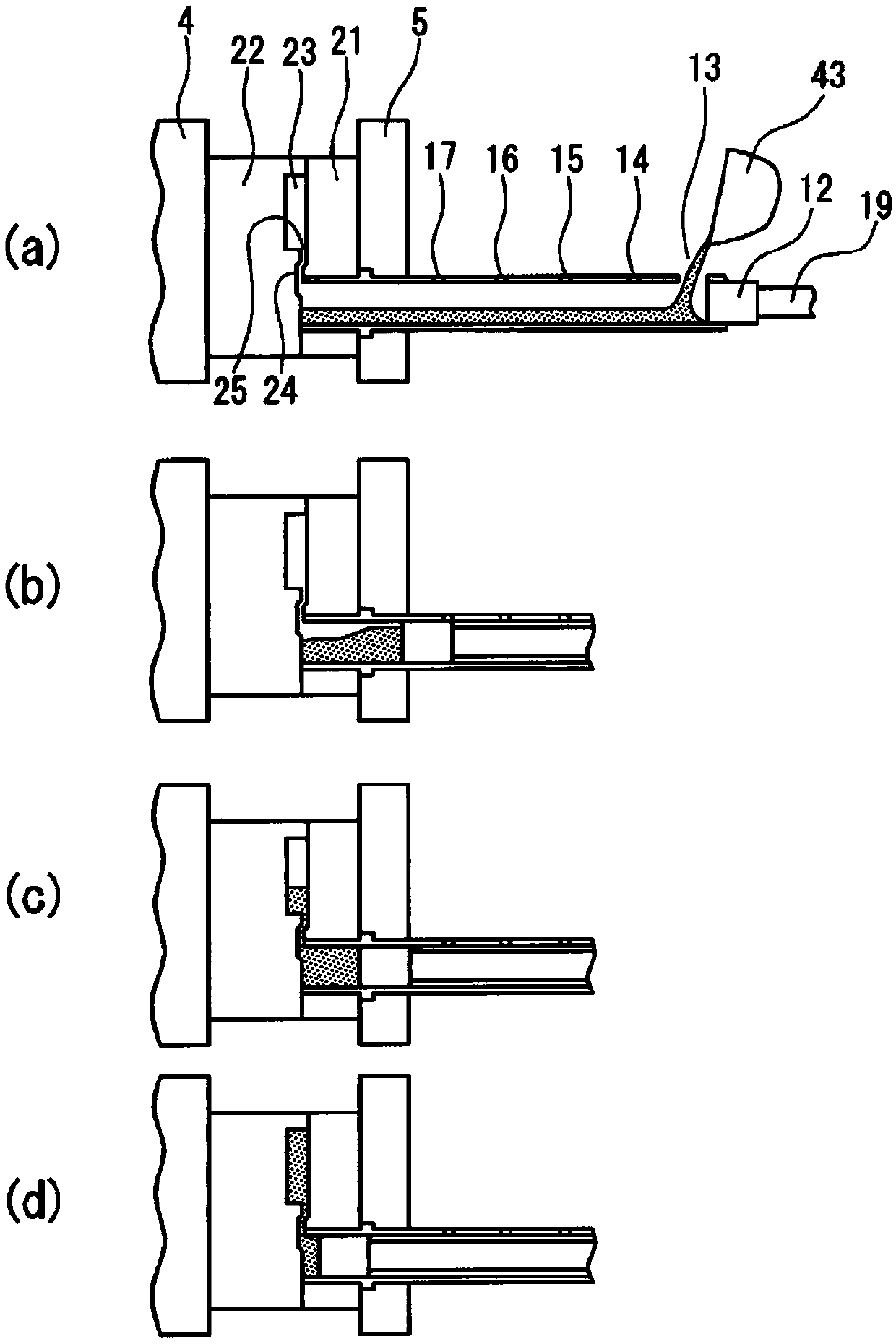

[0048] figure 1 It is a schematic side view (partial cross section is shown) of the die casting machine provided with the injection device 1 which concerns on one Embodiment of this invention.

[0049] In the die casting machine of this embodiment, the movable die 22 is provided on the movable platen 4 , and the fixed die 21 is provided on the fixed platen 5 . The movable platen 4 moves toward the fixed platen 5 side on the machine base 8 by means of a toggle mechanism, a ball screw mechanism, etc. for mold opening and closing, and a mold clamping mechanism (not shown). Thereby, the movable mold 22 and the fixed mold 21 are clamped (die clamped), and the cavity 23 is formed. Four connecting rods 7 pass through the movable platen 4 and the fixed platen 5 via through holes, and the movable platen 4 can freely move forward and backward relative to the fixed platen 5 along the connecting rods 7 . The fixed mold 21 and the movable mold 22 pass as figure 1 Engaged as shown, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com