Apparatus for producing an object by means of additive manufacturing and method of using the apparatus

A technology of additive manufacturing and objects, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problem of spending a lot of time, and achieve the effect of preventing lost time, reliable and precise removal, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

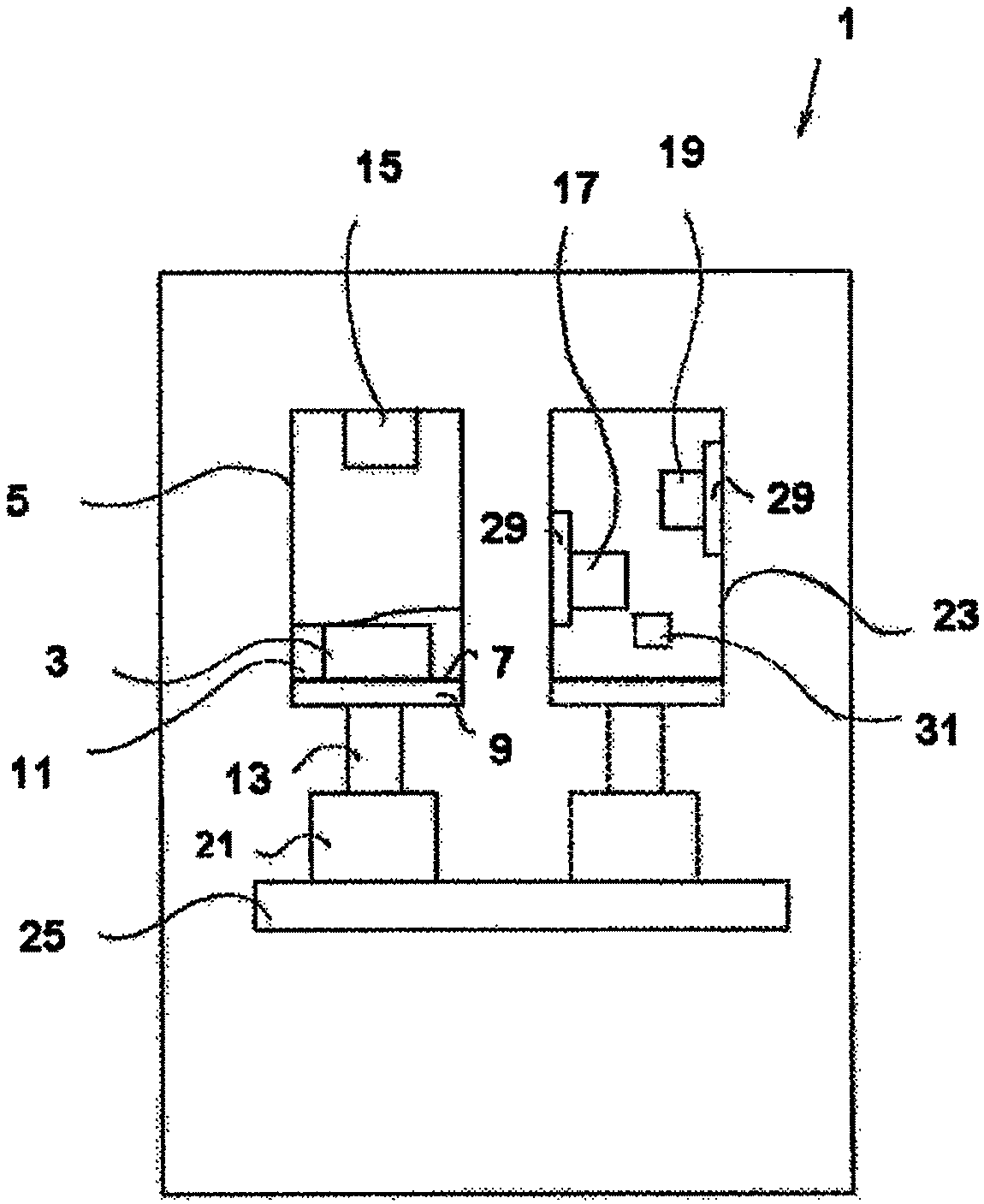

[0040] figure 1 An overview of a device 1 for producing objects 3 by additive manufacturing is shown. The apparatus 1 comprises a treatment chamber 5 for receiving a curable batch of powder material 11 and a post-treatment chamber 23 . A batch of powder material 11 is received on the build surface 7 of the build plate 9 . The build plate 9 can be positioned relative to the horizontal surface L of the batch of material 11 by means of supports 13 . The support 13 is movably arranged in the shaft 21 so that after curing a layer, the support 13 can be lowered and another layer of material can be cured on top of the already formed part of the object 3 . Curing means 15 are provided for curing selective portions of material 11 . In the illustrated embodiment, the solidification device 15 is a laser device arranged to generate electromagnetic radiation in the form of a laser in order to melt the powder material 11 provided on the support 13 and then, after cooling, form the Solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com