Process and apparatus for treating manure sludge

A sludge and manure technology, applied in agriculture and separation fields, can solve problems such as high phosphorus content limitation, and achieve the effects of reducing compaction, less manure storage, and accurate delivery of specific nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

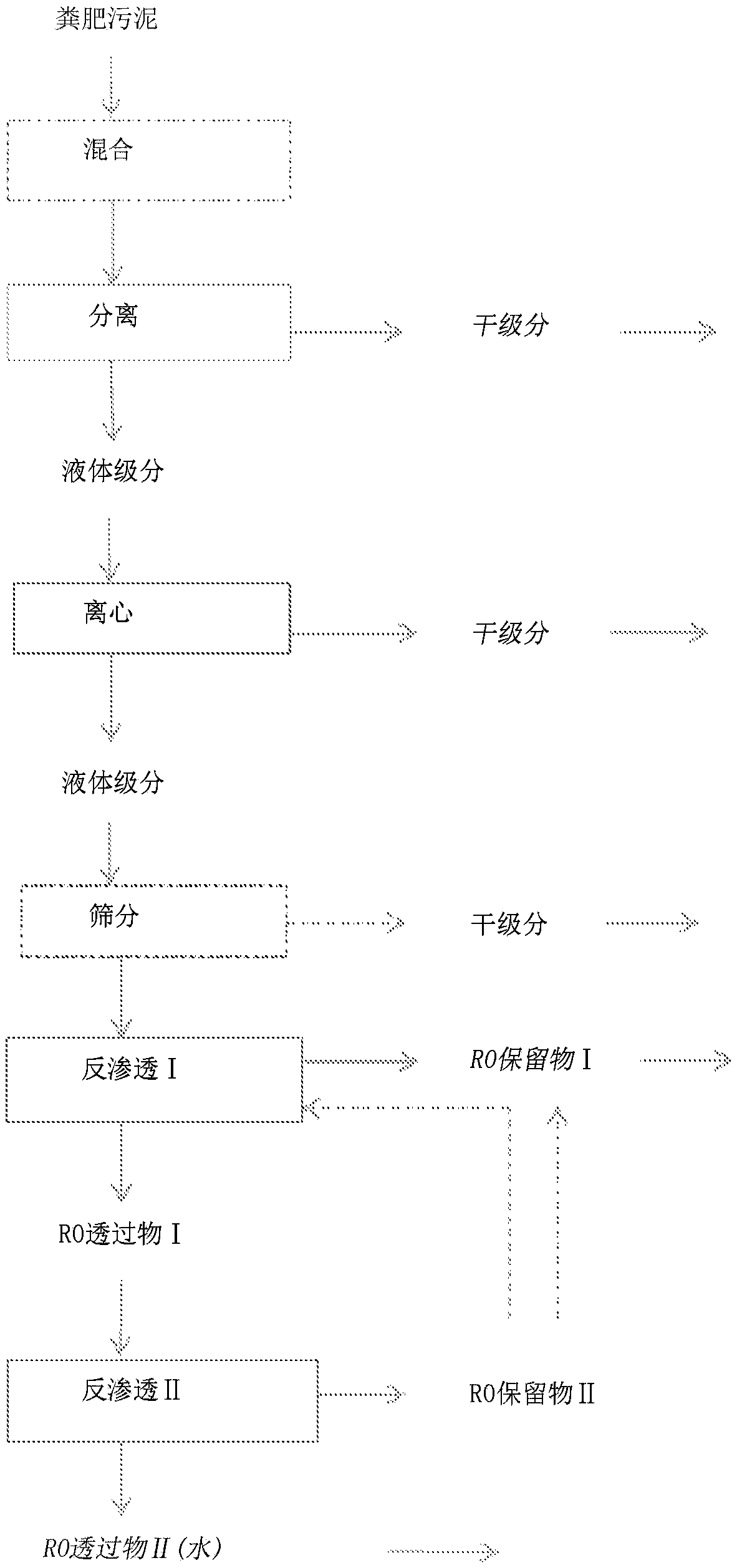

[0081] Process 1000 m of dry matter (DM) content of 8% by weight with a screw press (EYS SP600, mesh size: 0.5 mm) 3 Well mixed liquid cow manure sludge, which produced two fractions: 250 metric tons of dry fraction ("1st dry fraction"; 23% by weight DM) and 750 mt 3 Liquid fraction (3% by weight of DM).

[0082] The liquid fraction was pumped to a decanter centrifuge (Andritz Separation, model D5L, bowl speed: 3200 rpm, differential speed: 3.9 rpm, torque: 55 wt%, cell depth: 272 mm), which further removed suspended solids. Processing in a decanter centrifuge produced two fractions: 760m 3 Liquid fraction and 85 metric tons dry fraction ("2nd Dry Fraction"). After centrifugation, the dry matter contents of the liquid and dry fractions were <1% by weight and 18% by weight, respectively.

[0083] After centrifugation, the liquid fraction was pumped through a metal sieve with a mesh size of 80 μm to remove the largest particles.

[0084] After screening, the resulting liquid...

Embodiment 2

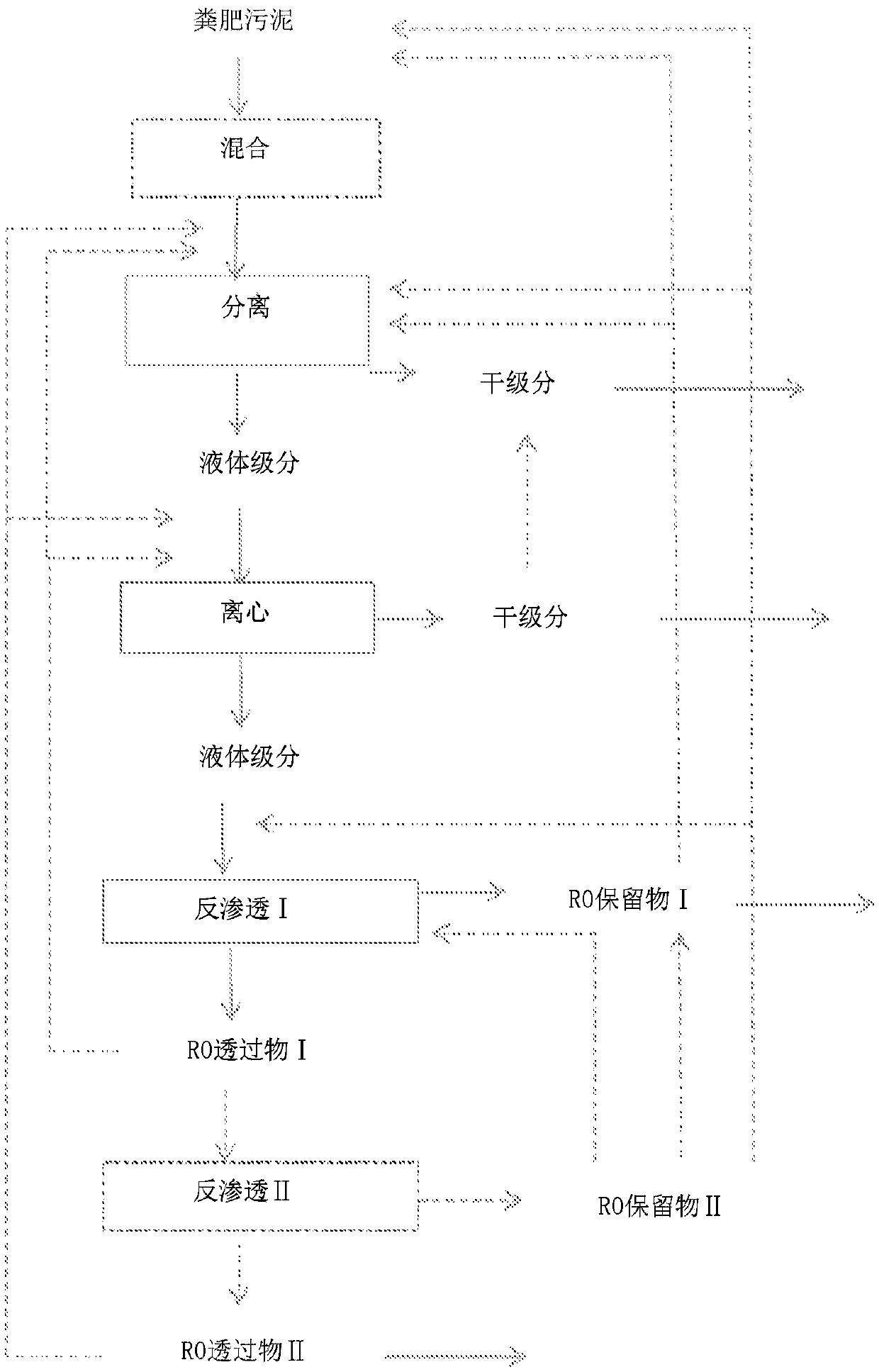

[0090] With a decanter centrifuge (Andritz Separation, D5L type, drum speed: 3200rpm, differential speed: 10rpm, torque: 70wt%, pool depth: 272mm) processing dry matter (DM) content is 1000m of 8% by weight. 3 Well-mixed liquid cow manure sludge, which produced two fractions: 225 metric tons of dry fraction ("1st dry fraction"; DM was 25% by weight) and 775 mt 3 Liquid fraction (3% by weight of DM).

[0091] The liquid fraction was pumped to a decanter centrifuge (Andritz Separation, model D5L, bowl speed: 3200 rpm, differential speed: 3.9 rpm, torque: 55 wt%, cell depth: 272 mm), which further removed suspended solids. Processing in decanter centrifuge produced dry and liquid fractions: 695m 3 Liquid fraction and 80 metric tons of dry fraction ("2nd dry fraction"). After centrifugation, the dry matter contents of the liquid and dry fractions were 0.5% by weight and 25% by weight, respectively.

[0092] Liquid from centrifugation was pumped to a reverse osmosis (RO) facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com