Automatic feeding device and method of cylindrical lithium battery assembled by wearable intelligent device

A smart device and automatic feeding technology, applied in the field of electronic communication, can solve problems such as complex structure installation, difficulty in meeting production requirements, and low battery assembly efficiency, so as to increase working capacity, avoid excessive correction, and facilitate subsequent assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

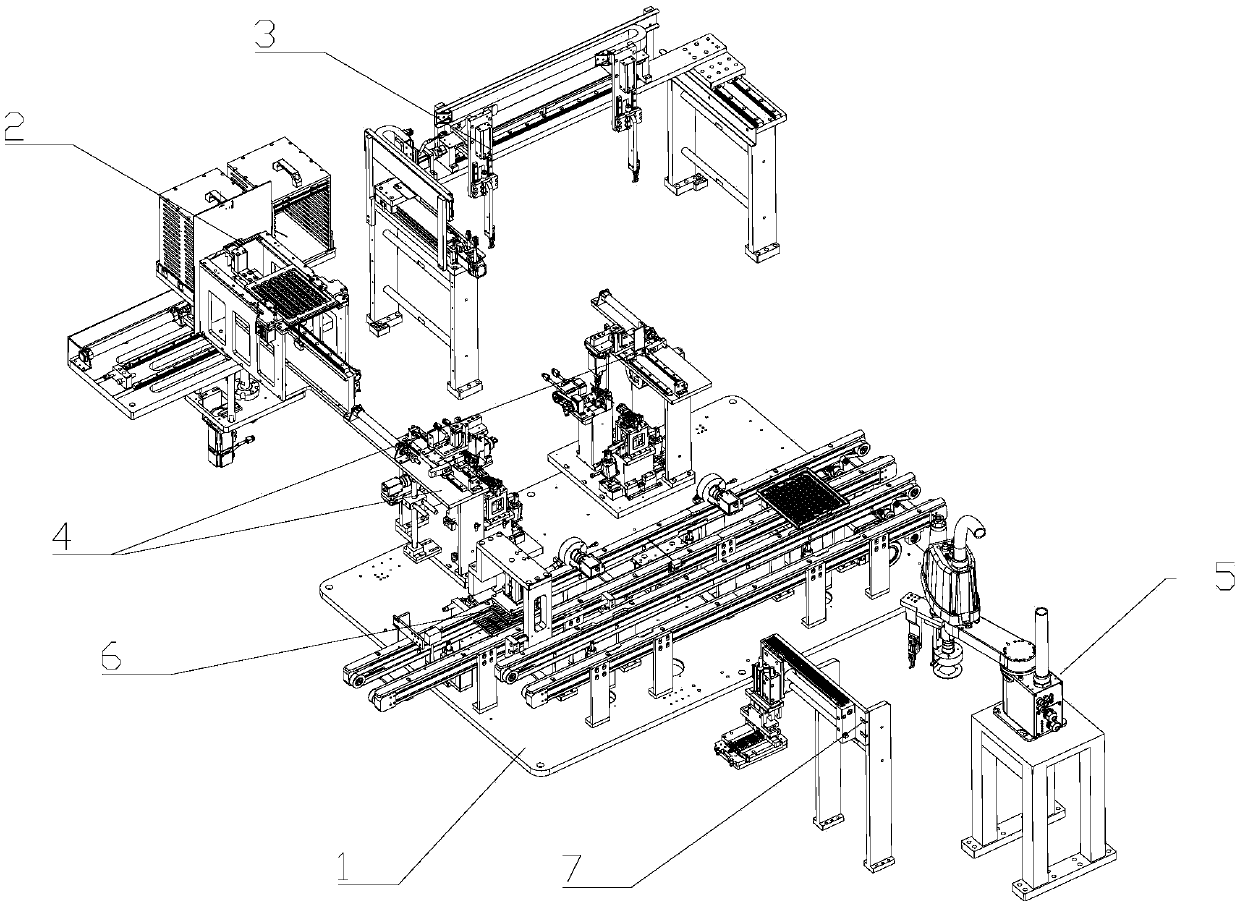

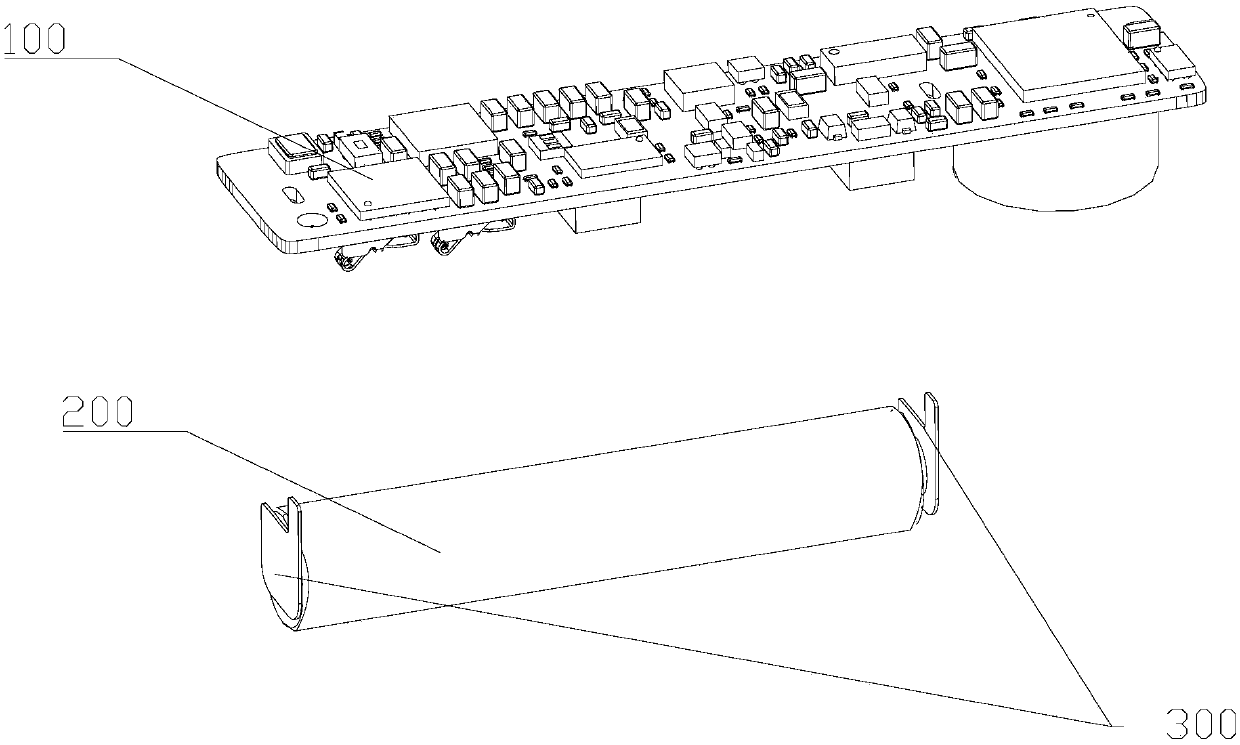

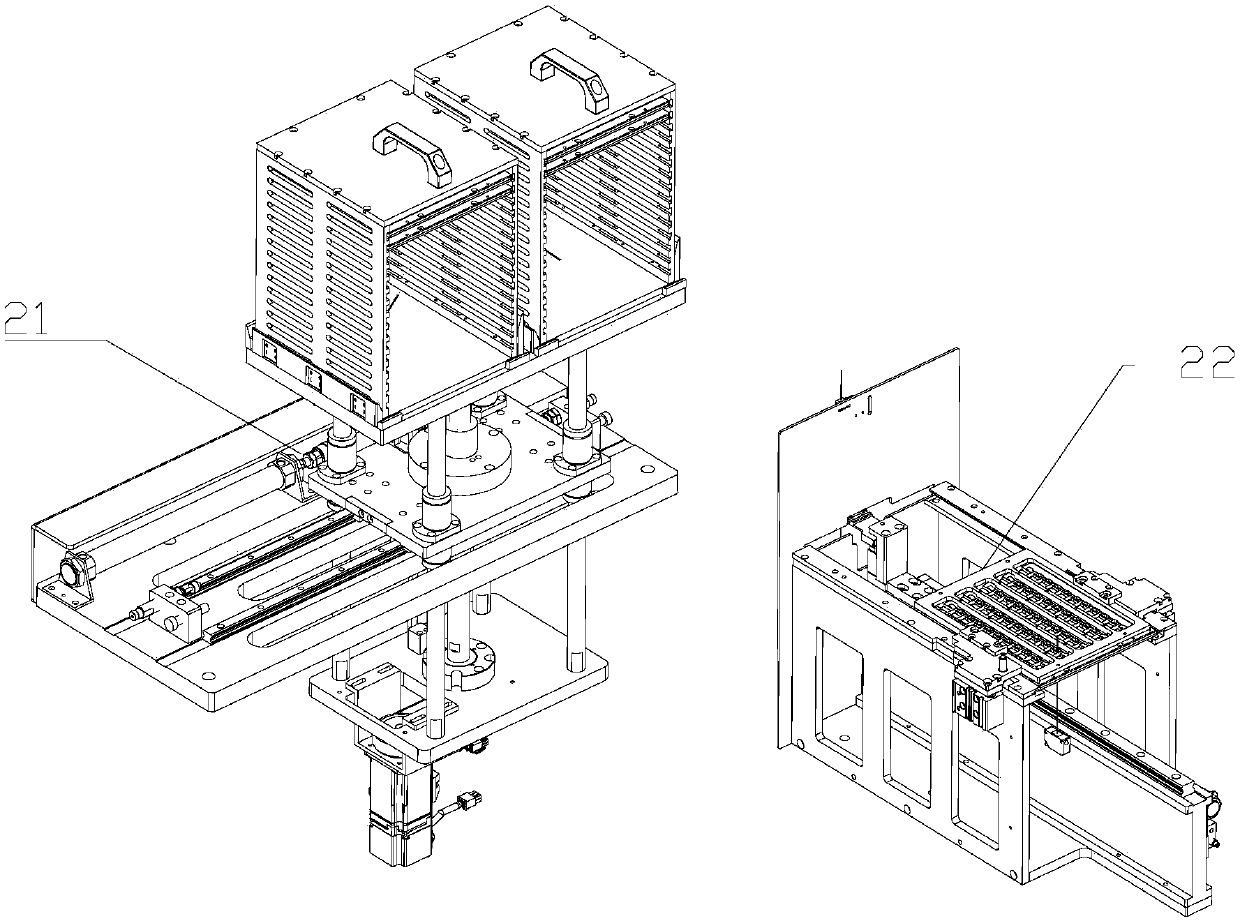

[0032] Such as figure 1As shown, the lithium battery automatic assembly equipment for wearable smart devices includes a frame 1 and a battery feeding device 2 installed on the frame 1, a first handling device 3, a lithium battery shaping device 4, a second handling device Device 5, assembly line device 6 and third handling device 7; battery feeding device 2 and first handling device 3 form a cylindrical lithium battery automatic feeding device assembled by wearable smart devices; battery feeding device 2 is used for loading batteries material, the first handling device 3 is located above the battery feeding device 2, and is used to carry the battery. Below, it is used to reshape the battery; the second handling device 5 is used to transport the reshaped battery; the assembly line device 6 includes two assembly lines, which are used for loading, assembling and unloading of finished products for each component, and the third The transport device 7 is located above the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com