Composite textile machine with a tape accumulating unit for the intermediate storage of fibre tape

一种存储单元、中间存储的技术,应用在纺纱机、纤维处理、纤维喂入等方向,能够解决纤维条打结、损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

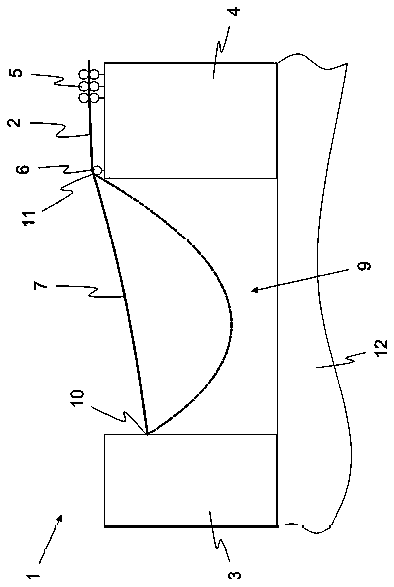

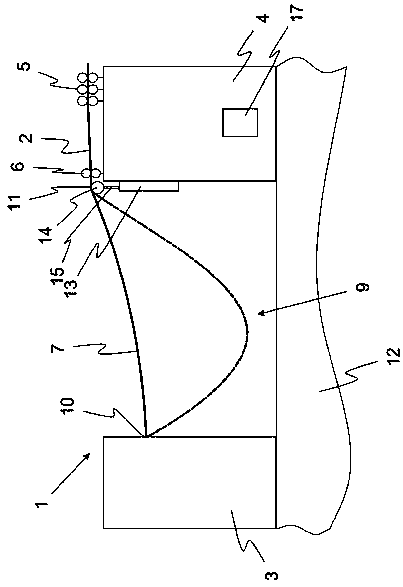

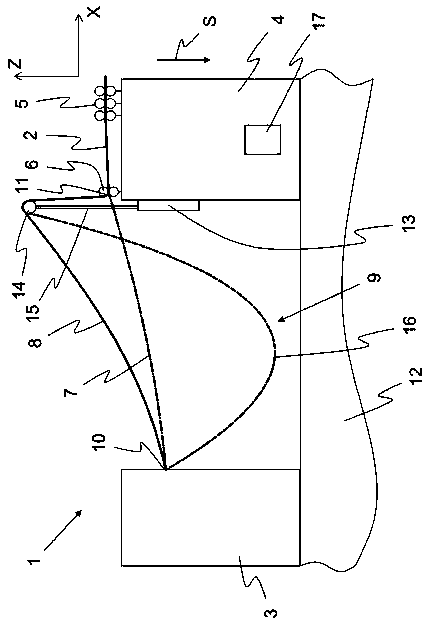

[0049] figure 1 A textile machine complex 1 with a supply unit 3 and a receiving unit 4 is shown.

[0050] The fiber strip 2 is supplied during operation of the textile machine complex 1 by means of the supply unit 3 . The supply unit 3 can be, for example, a card which can card textile fibers. However, the supply unit 3 can also be another unit which supplies the fiber sliver 2 . The feed unit 3 can feed the fiber sliver 2 at a feed speed during operation. This feed speed can be, for example, 10 m / min. Thus, 10 meters of fiber sliver are fed per minute by the feeding unit 3 .

[0051] The fiber strip 2 supplied by the supply unit 3 is received during operation of the textile machine complex 1 by means of the receiving unit 4 . According to the present embodiment, the receiving unit 4 is a draw frame with a drafting device 5 . However, the receiving unit 4 can also be a further unit which receives the fiber sliver 2 . According to the present exemplary embodiment, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com