Variable-diameter variable-intercept spiral sorting mechanism

A technology of spiral separation and intercept, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of energy waste, low utilization rate of combustion equipment, exacerbated external loss and internal loss of clean coal, etc. Achieve the effects of convenient operation, improved equipment combustion efficiency, and enhanced sorting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

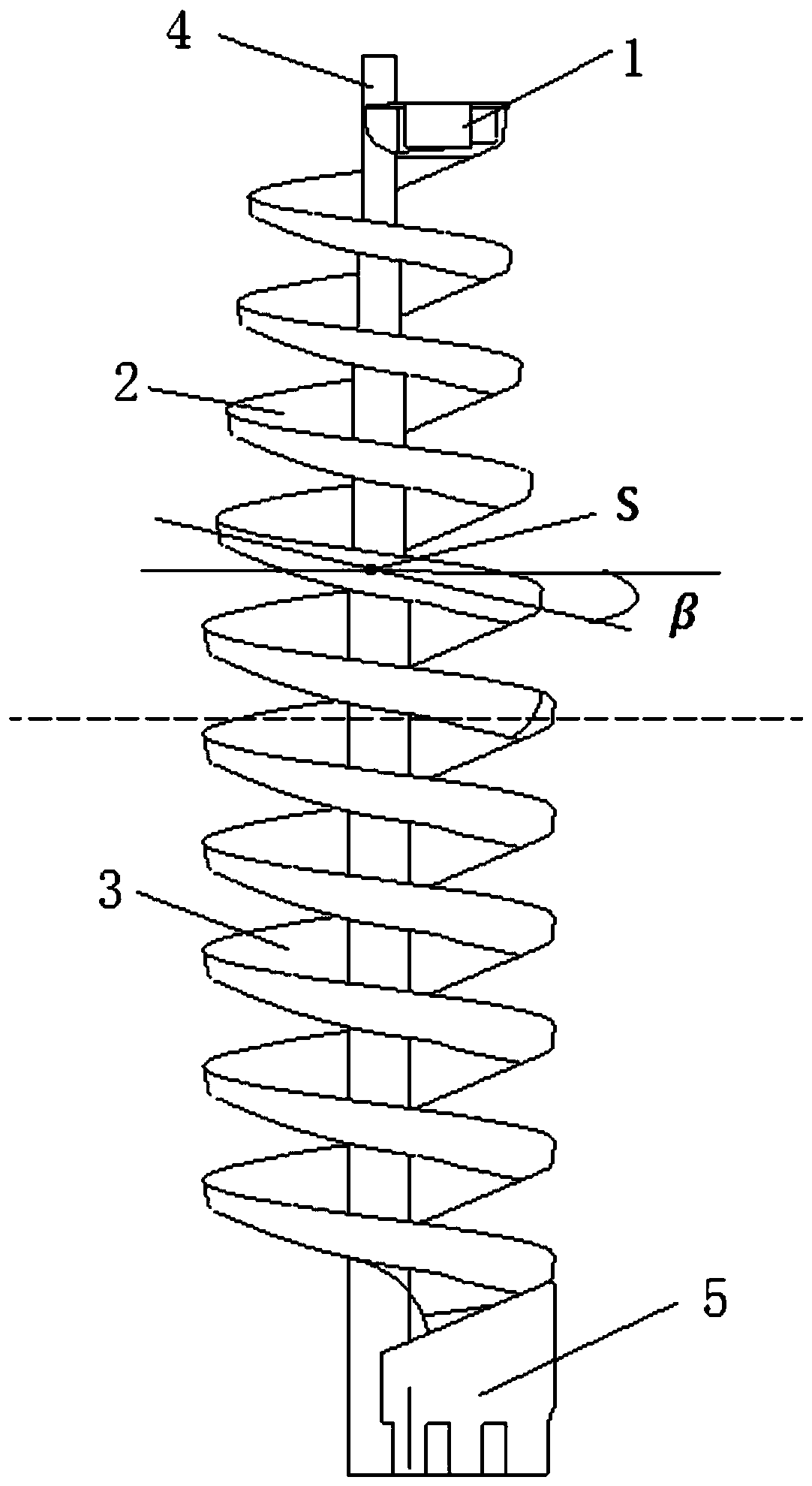

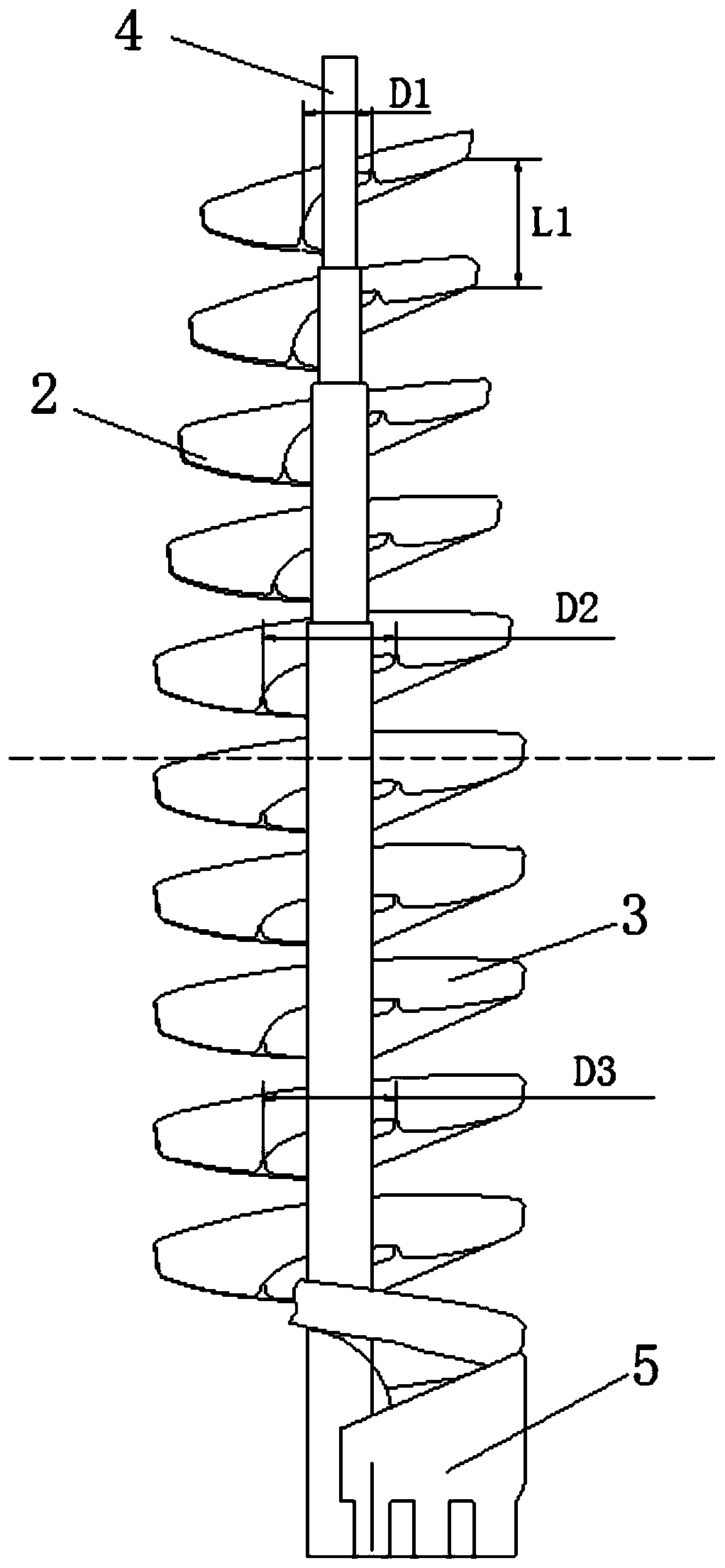

[0034] This embodiment provides a variable-diameter, variable-intercept spiral sorting mechanism, such as figure 1 As shown, it includes a central column 4, a spiral sorting sheet, a feed port 1 and a discharge port 5, wherein the spiral sorting sheet is spirally arranged on the outer wall of the central column 4; the feed port 1 is arranged on The upper part of the central column 4, the discharge port 5 is arranged at the bottom of the central column 4; the upper surface of the spiral sorting sheet is formed with a spiral sorting groove along the length direction of the spiral sorting sheet, and the The upper end of the spiral sorting tank is connected with the feed inlet 4, and the lower end is connected with the discharge port 5; the spiral sorting tank includes a variable-diameter spiral sorting tank part 2 and a variable-intercept spiral sorting tank part 3 , and the variable-diameter spiral sorting groove part 2 is located above the variable-intercept spiral sorting groo...

Embodiment 2

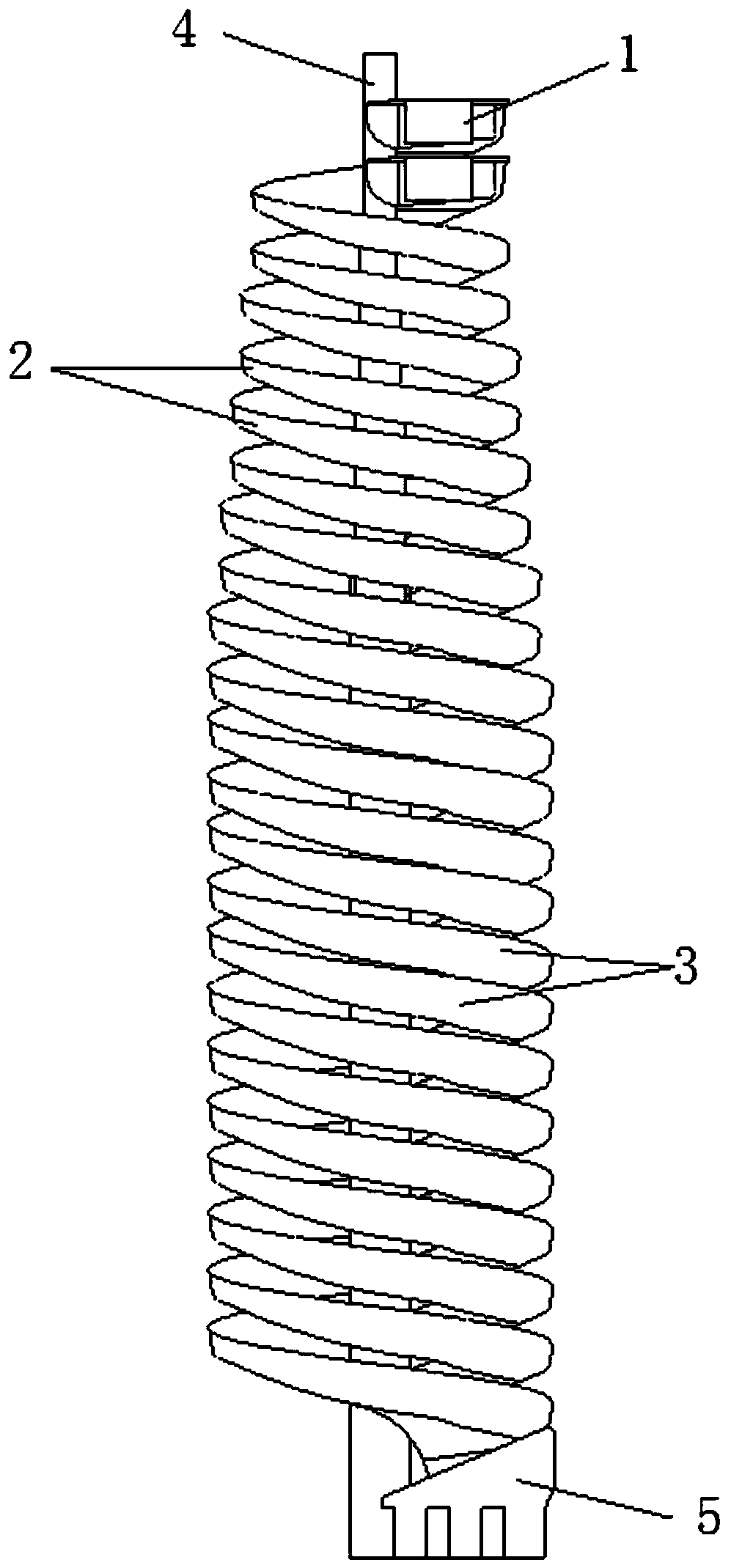

[0041] The variable-diameter, variable-intercept spiral sorting mechanism that present embodiment provides, such as image 3 As shown, the number of spiral sorting sheets is two, and the two spiral sorting sheets are wound on the central column 4 at intervals, and the two feeding ports 1 corresponding to the two spiral sorting sheets are arranged up and down. In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1, and will not be described in detail in this embodiment.

Embodiment 3

[0043] This embodiment provides a spiral separator, such as Figure 4 and Figure 5 shown. The spiral separator comprises a mounting bracket 6, a feed distributor 7 and a shunt pipe 8, the feed distributor 7 is fixedly installed on the top of the installation bracket 6, and one end of the shunt pipe 8 is connected to the feed distributor 7 The bottom outlet is connected, the other end of the shunt pipe 8 is connected to the feed port 1, and the central column 4 is vertically fixed on the mounting bracket 6.

[0044] like Figure 4 and Figure 5 As shown, the number of the spiral sorting sheet and the shunt pipe 8 are equal and multiple (two are shown in the figure, and there can be more according to actual needs), each of the spiral sorting sheets passes through a The root shunt pipe 8 is connected with the bottom outlet of the feed distributor 7 .

[0045] The quantity of the spiral sorting mechanism in each described spiral sorter among the figure can be set, Figure 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com