Pocket hole slashing device of laser pocket machine

A bag opening machine and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unreasonable structure, reduce installation space, shorten service life, etc., achieve simple and convenient debugging, and improve cutting accuracy , The effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

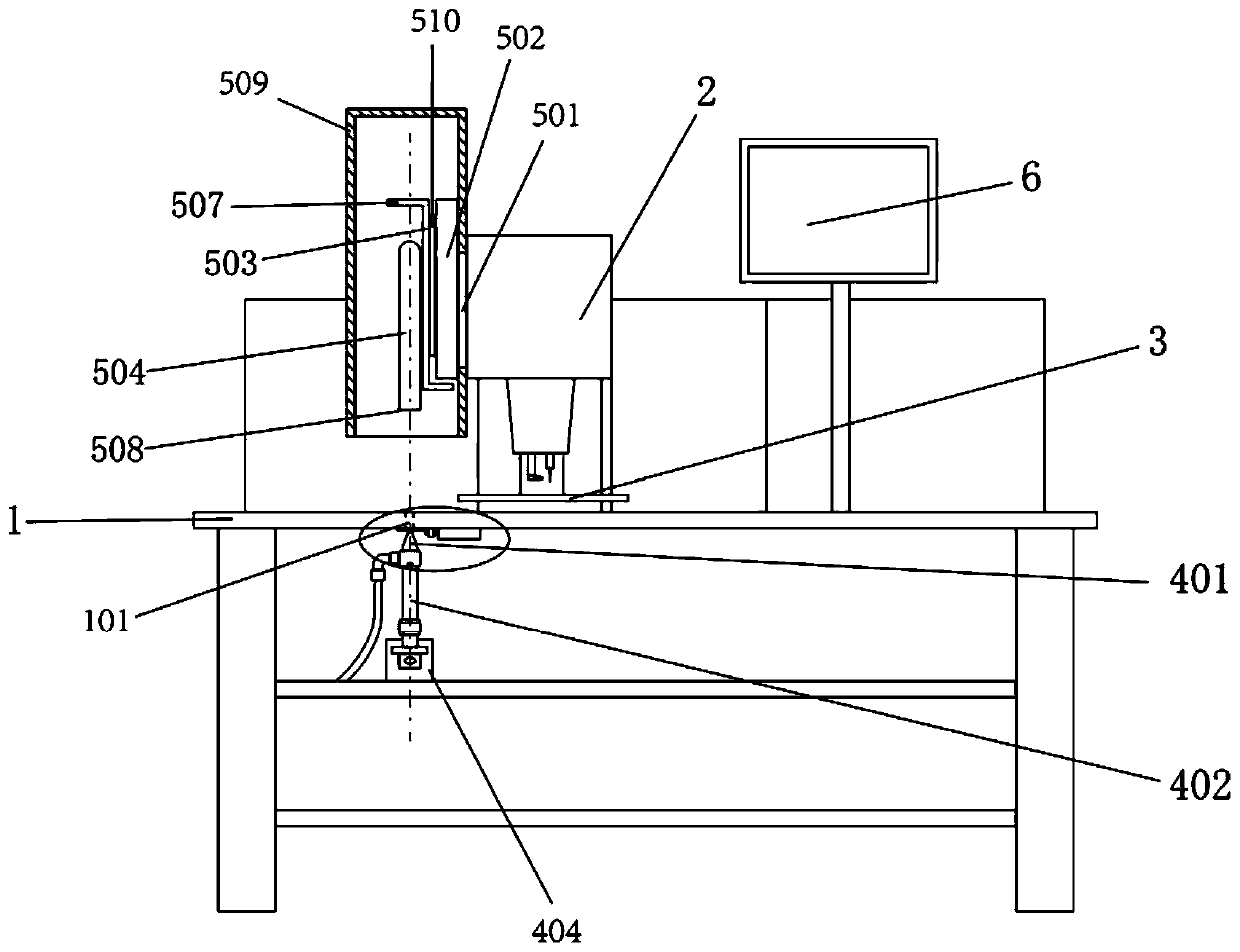

[0054] according to Figure 5 , combined with Figure 1-4 , in the upper air suction assembly described in the embodiment, the lifting mechanism 502 is a cylinder, and Xingchen TDA10-60 cylinder can be used. Described cylinder comprises cylinder body 516, telescopic guide rod 517, and the upper end of described telescopic guide rod 517 is connected in described cylinder body 516, and the lower end of described telescopic guide rod 517 stretches out the bottom of described cylinder body 516, and described The bottom of the telescopic guide rod 517 is provided with a connecting block 518 .

[0055] Described slide rail 510 is mainly made up of slide block 514 and track 513, and described track 513 is fixed on the described cylinder body 516, and described slide block 514 slides up and down on described track 513, and described slide block 514 and The laser protection plate 503 is fixedly connected; the top of the laser protection plate 503 is provided with a transverse baffle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com