Dotting positioning device for assembling an air conditioning compressor liquid storage device steel connecting pipe and a barrel

A technology for air-conditioning compressors and positioning devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of out-of-synchronization of the running speed and displacement of the main shaft of the hydraulic cylinder, slow response speed of the cylinder drive, and poor consistency of the dot depth. Achieve the effects of reducing power consumption and waste liquid discharge, improving welding quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

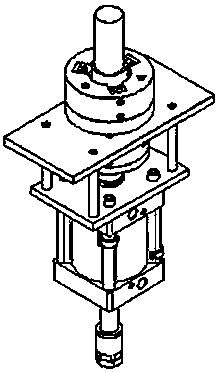

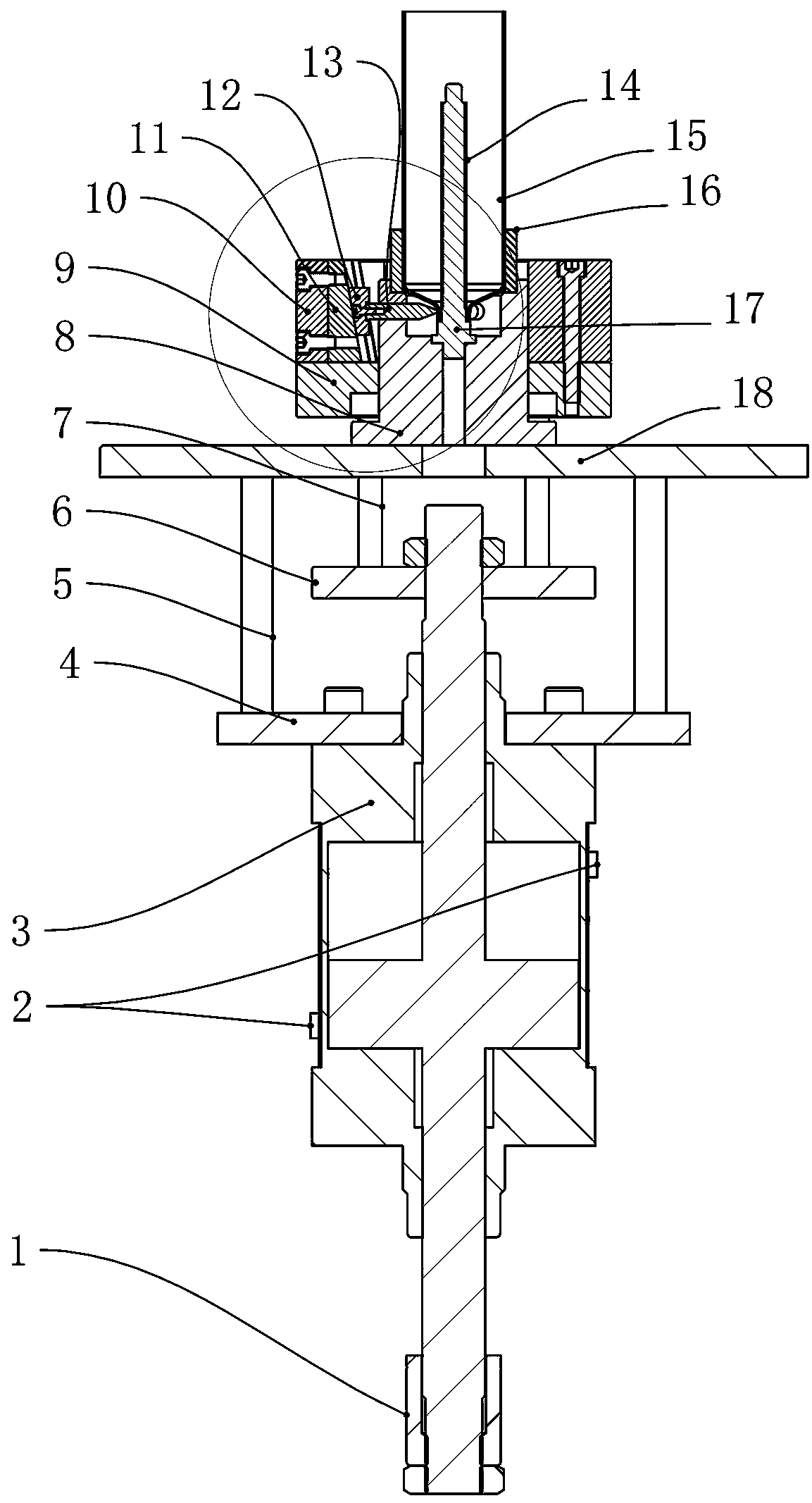

[0019] Such as figure 1 , figure 2 As shown, the air-conditioning compressor liquid accumulator steel connection pipe and cylinder body of the present invention are assembled with a punching and positioning device, including a frame and clamping die parts, a power mechanism, a punching and stamping mechanism and a control part. in,

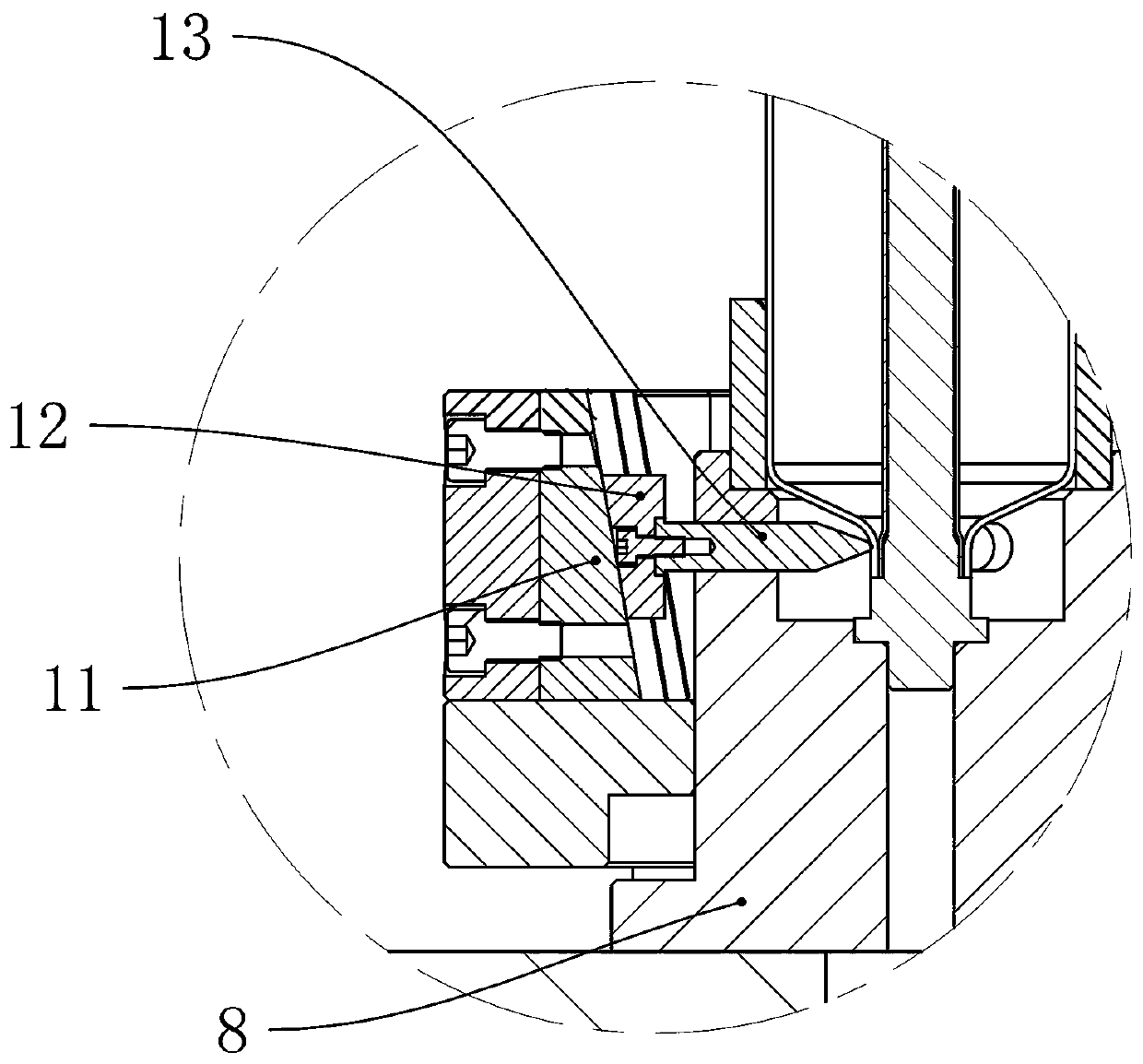

[0020] The clamping part refers to the mold core 8 fixedly installed on the connection base plate 18; the upper cavity of the mold core is provided with a ring sleeve outside the cylinder 15, a cylinder positioning sleeve 16 for positioning, and a cylinder positioning sleeve 16 inserted into the steel A steel pipe positioning mandrel 17 for supporting in the pipe 14;

[0021] The power mechanism is driven by a cylinder 3, the cylinder 3 is fixed on the cylinder fixed plate 4, the connecting base plate 18 is arranged in parallel with the cylinder fixed plate 4, and the connection support is realized by fixing the connecting rod 5 between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com