Expandable small-sized chassis type battery swap station applying transfer trolley

A technology of changing power stations and trolleys, which is applied in the field of changing stations, which can solve the problems of not being able to fully automatically change batteries, low expansion, and large floor space, and achieve the effects of improving power changing effects, flexible transportation, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

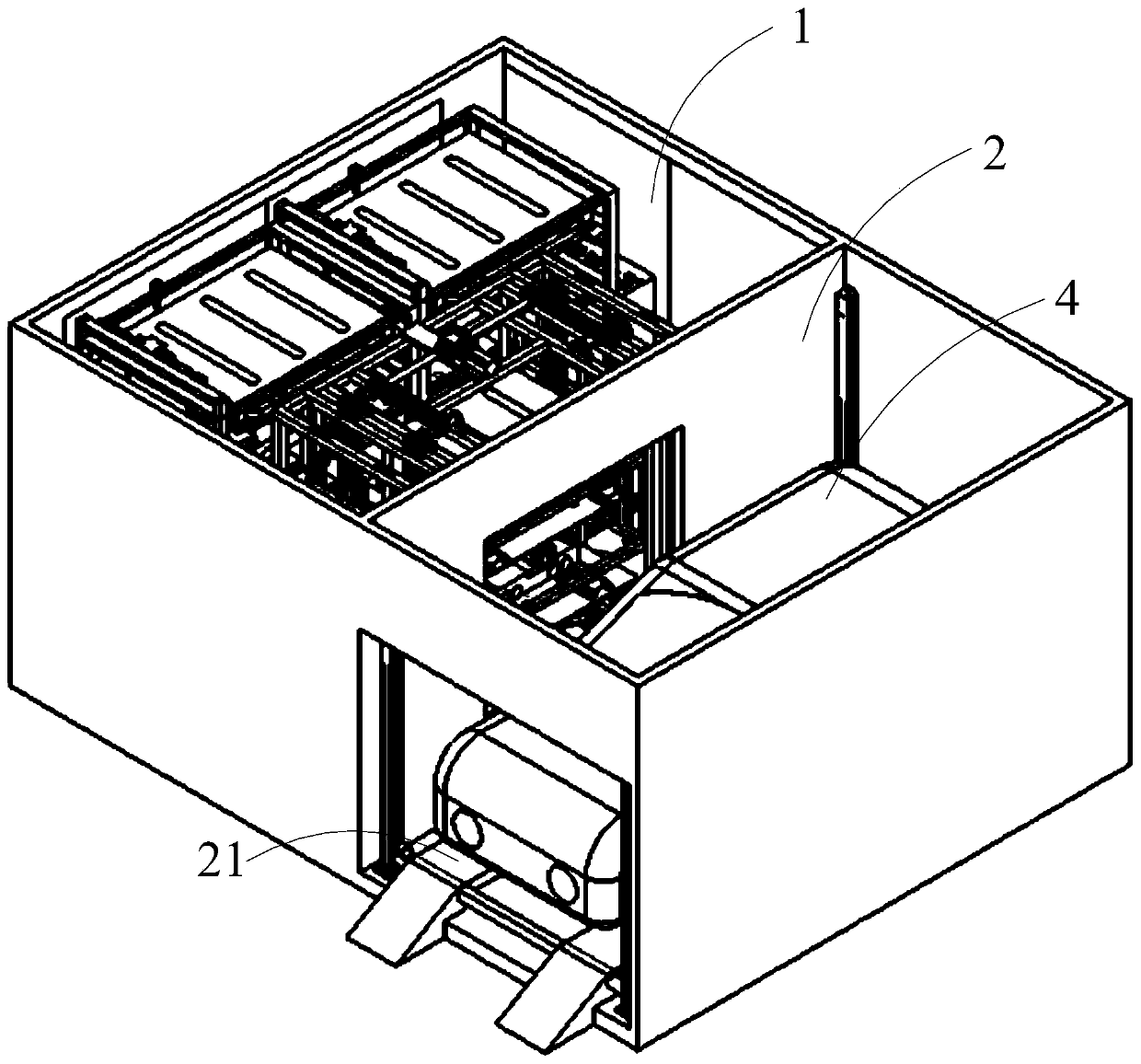

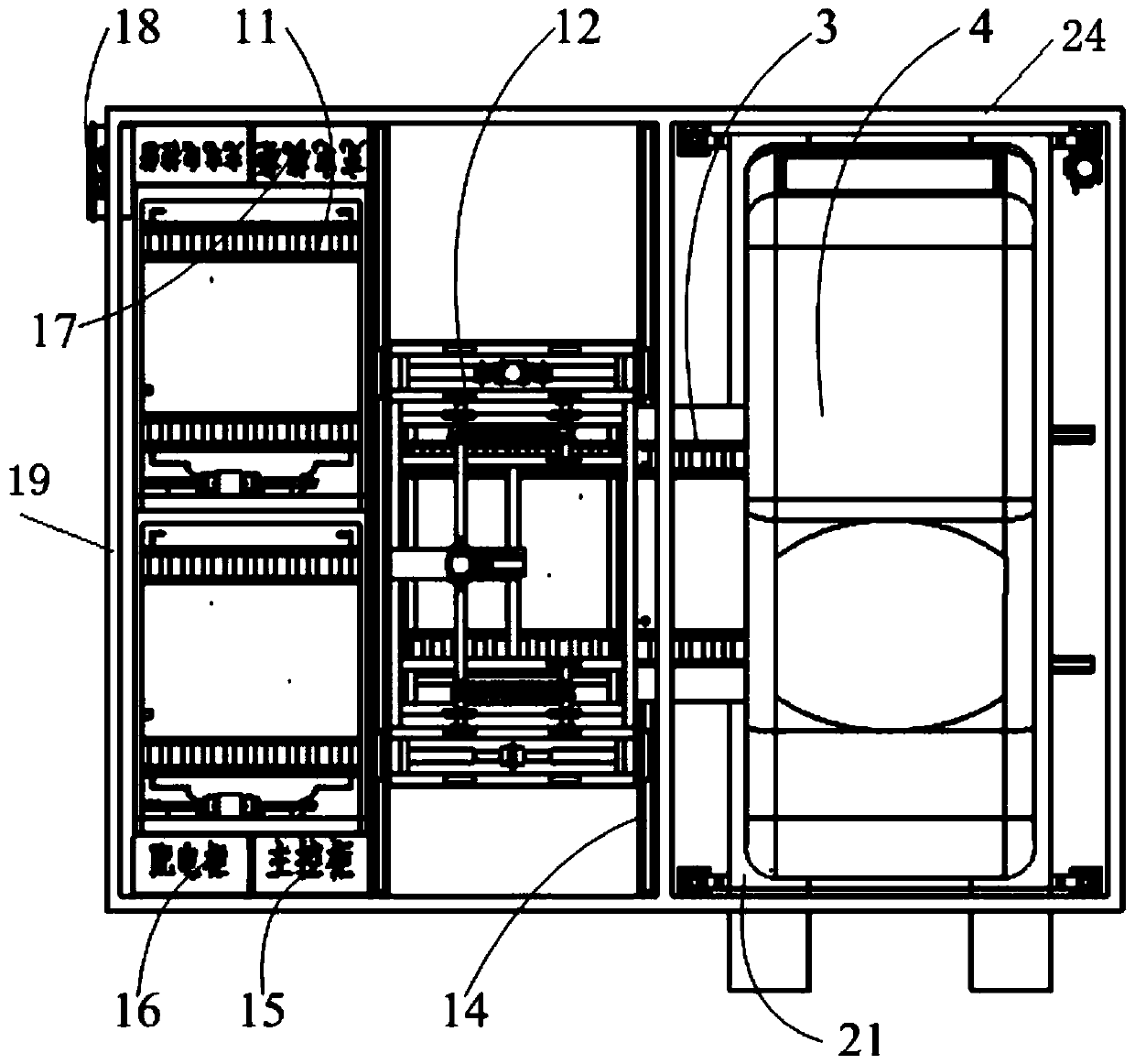

[0036] see figure 1 with figure 2 , an expandable small chassis-type battery-swapping station using a transfer trolley, including a charging container 1, a battery-swapping container 2, and an RGV battery-swapping trolley 3 reciprocating between the charging container 1 and the battery-swapping container 2. The RGV battery exchange trolley 3 can move back and forth between the charging container 1 and the battery exchange container 2, and transports the battery 5 in the electric vehicle 4 back and forth between the electric vehicle 4 and the hoist 12 .

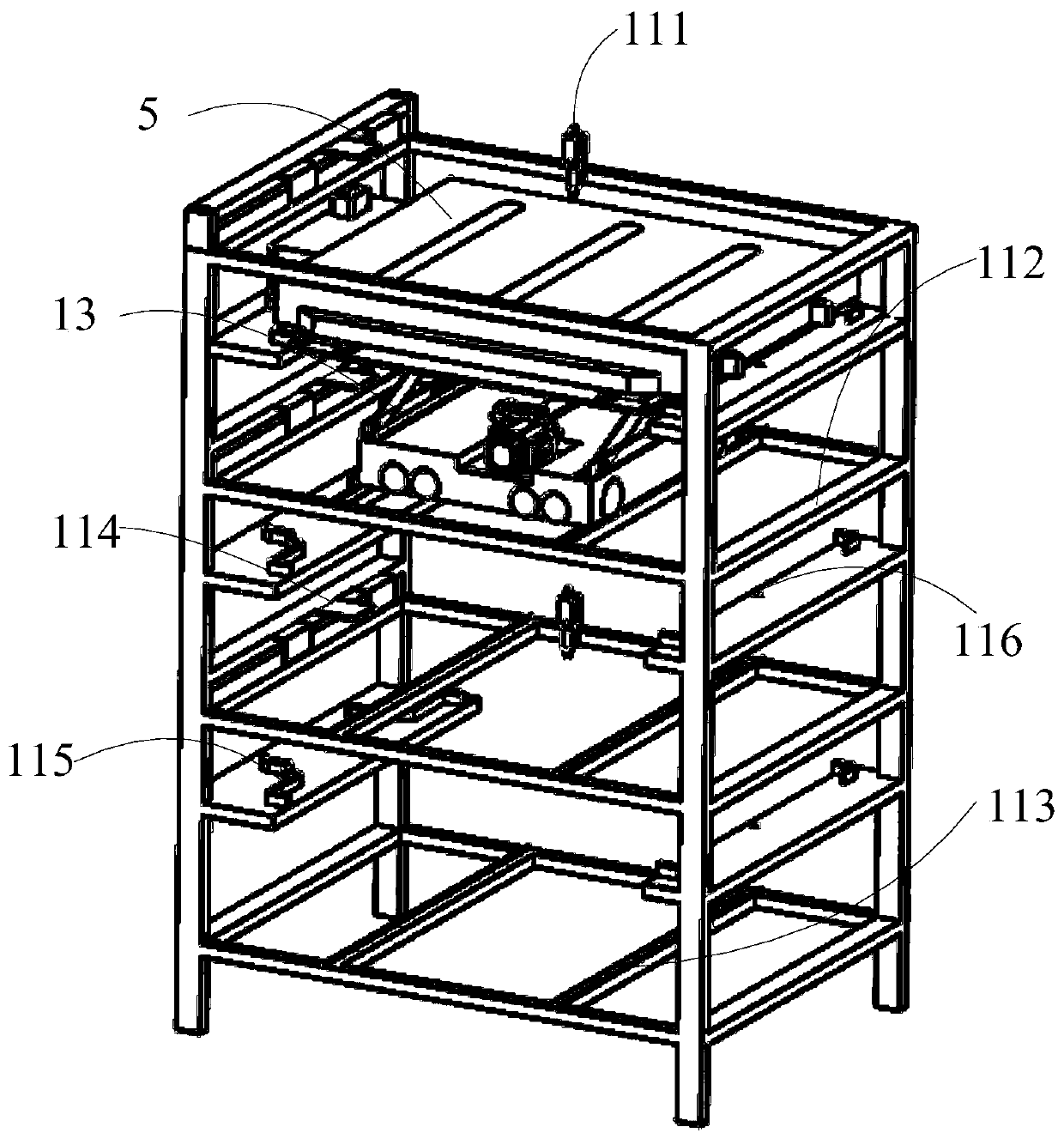

[0037] The charging container 1 includes a first box body 19 and a hoist 12 arranged inside the first box body 19, a transfer trolley 13, a hoist rail 14, a main control cabinet 15, a power distribution cabinet 16, a charging system 17 and a plurality of battery racks 11. A plurality of battery racks 11 are arranged side by side along the length direction of the first box body 19; the hoist track 14 is embedded in the botto...

Embodiment 2

[0050] see Figure 9 , the structure of embodiment 2 is similar to that of embodiment 1, the only difference is that expansion containers 6 are arranged side by side on the outside of charging container 1, and expansion container 6 includes a third box body 62 and extended battery racks arranged side by side in the third box body 62 63 and transition battery rack 61.

[0051] The extension container 6 adopts the transitional battery rack 61 instead of the hoist 12, which can realize the overall flexible expansion of the battery swapping station to meet more battery swapping vehicles. Among them, the transitional battery rack 61 is used for the transfer car 13 to and fro, and the four-way transport battery 5 is between the charging container 1 and the expansion container 6, which realizes the unlimited expansion capability of one transfer car 13 and saves the expansion cost. The structure of the extended battery rack 63 is the same as that of the battery rack 11 .

[0052] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com