Heavy oil viscosity reducer

A viscosity reducer and initiator technology, applied in the field of viscosity reducer and its preparation, can solve the problems of poor temperature resistance, achieve good temperature resistance, improve salt and temperature resistance, and good viscosity reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

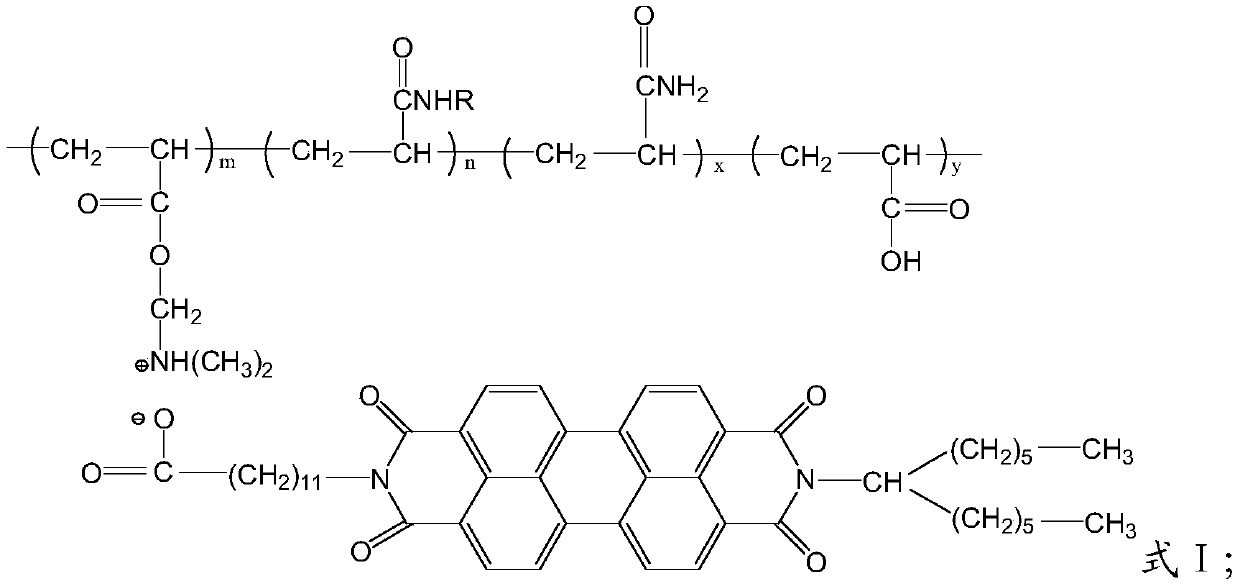

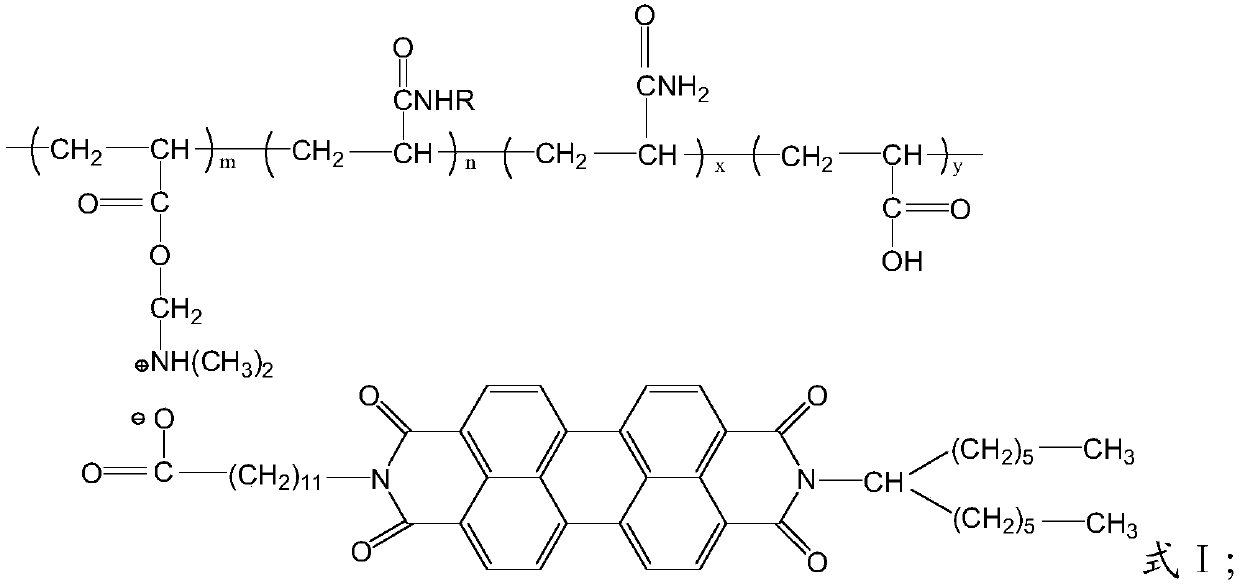

[0027] The present invention also provides a preparation method of the viscosity reducer, comprising the following steps:

[0028] Mix monomer Ⅰ, monomer Ⅱ, acrylamide, acrylic acid and initiator, and polymerize to obtain a viscosity reducer;

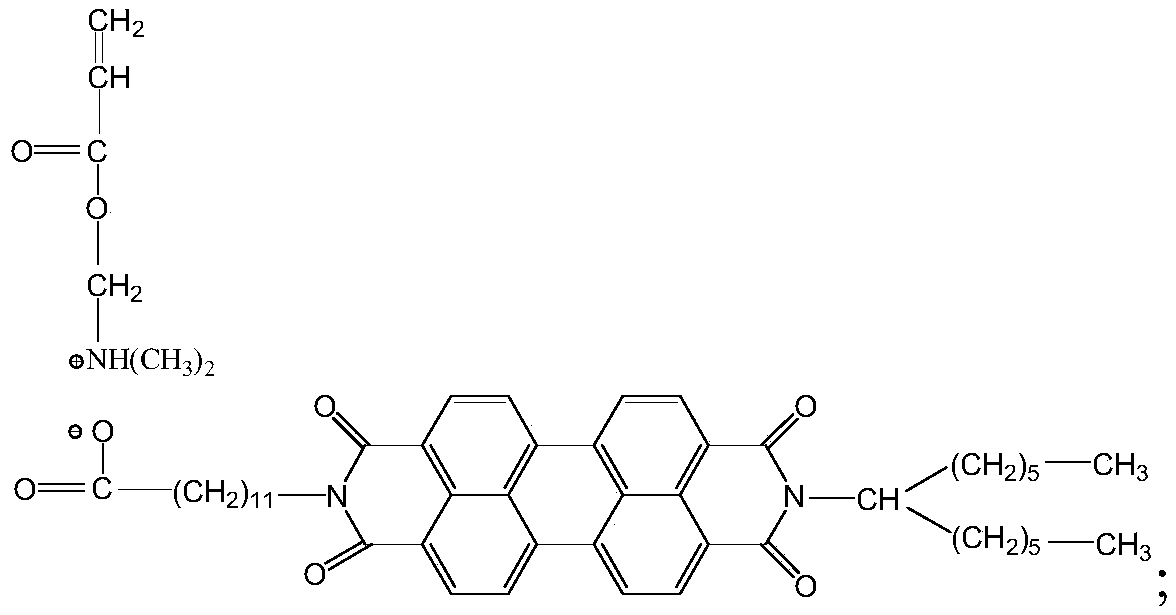

[0029] The monomer I is:

[0030]

[0031] The monomer II is: CH 2 =CH-CONHR, R is a C1-C20 alkyl group.

[0032] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0033] In the present invention, the initiator is preferably one or more of azobisisobutyronitrile, azobisisovaleronitrile and azobisisoheptanonitrile; When there are more than two kinds, the present invention does not have any special limitation on the ratio of the specific substances, and they can be mixed in any proportion.

[0034] In the present invention, the molar ratio of the initiator to acrylamide is preferably 1:(8000-12000), more preferably 1:(9000-...

Embodiment 1

[0053] According to the ratios of m, n, x, and y shown in Table 1, monomer I, monomer II (R is a C15 alkyl group), acrylamide, acrylic acid, and azobis in a molar ratio of 1:10000 to acrylamide Isobutyronitrile was mixed and reacted for 6 hours under stirring at 40°C and normal pressure; the resulting system was precipitated with methanol, purified, and dried in vacuum to obtain a viscosity reducer.

Embodiment 2

[0055] At 40°C, the viscosity reducer prepared in Example 1 was mixed with conventional heavy oil from Bohai Oilfield to test the viscosity of the heavy oil. The test results are shown in Table 1:

[0056] The viscosity reducing agent of table 1 embodiment 1 is to the viscosity reducing experiment result of heavy oil

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com