Injection molding process of plastic basin

A technology of plastics and craftsmanship, applied in the field of injection molding of plastic pots, can solve the problems of affecting the health of workers in the processing environment, the low fluidity of hot-melt plastics, and affecting the flow of plastics, so that it is not easy to break, improve hardness, and improve integrity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

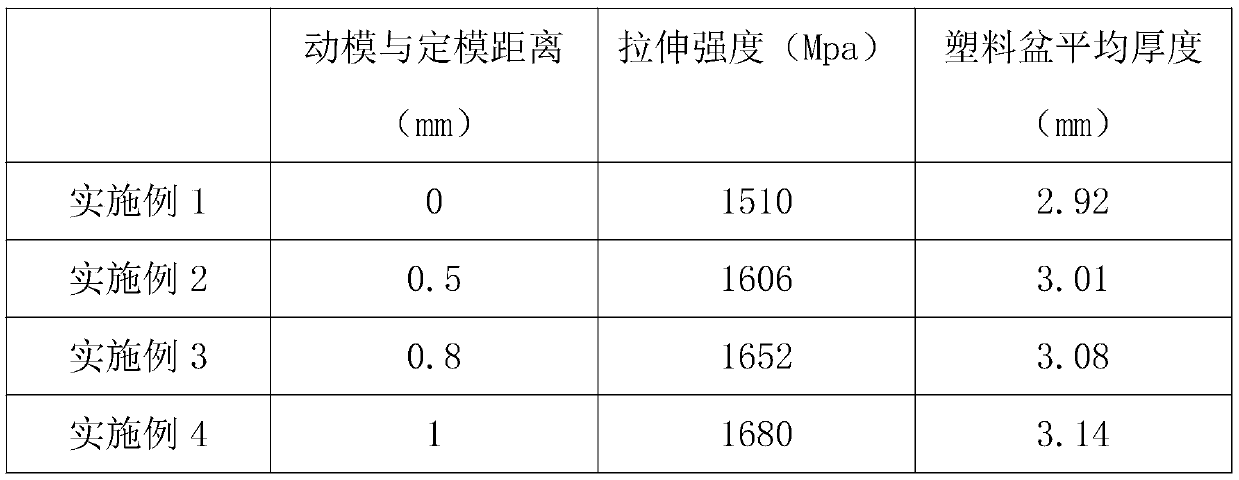

Examples

Embodiment 1

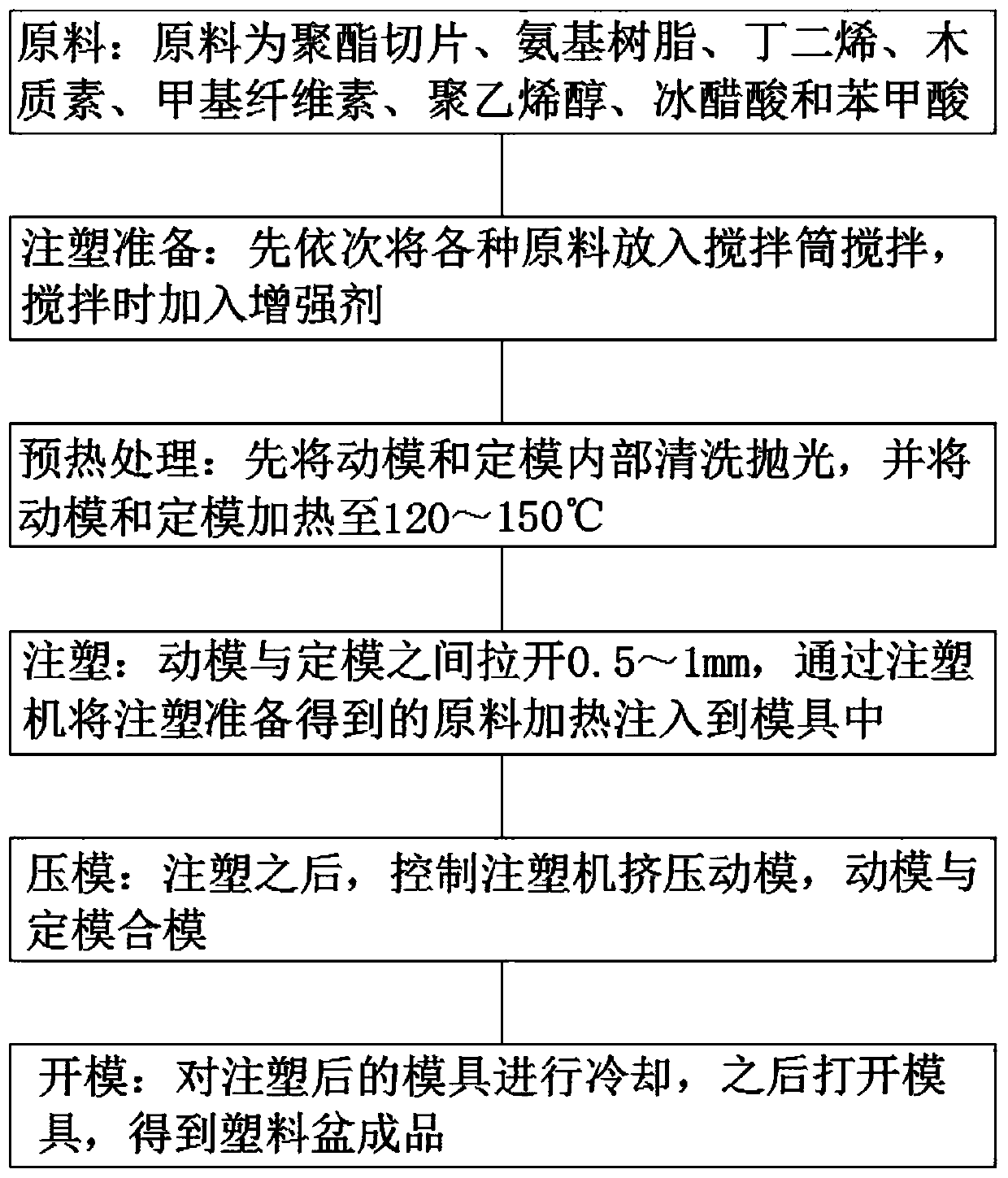

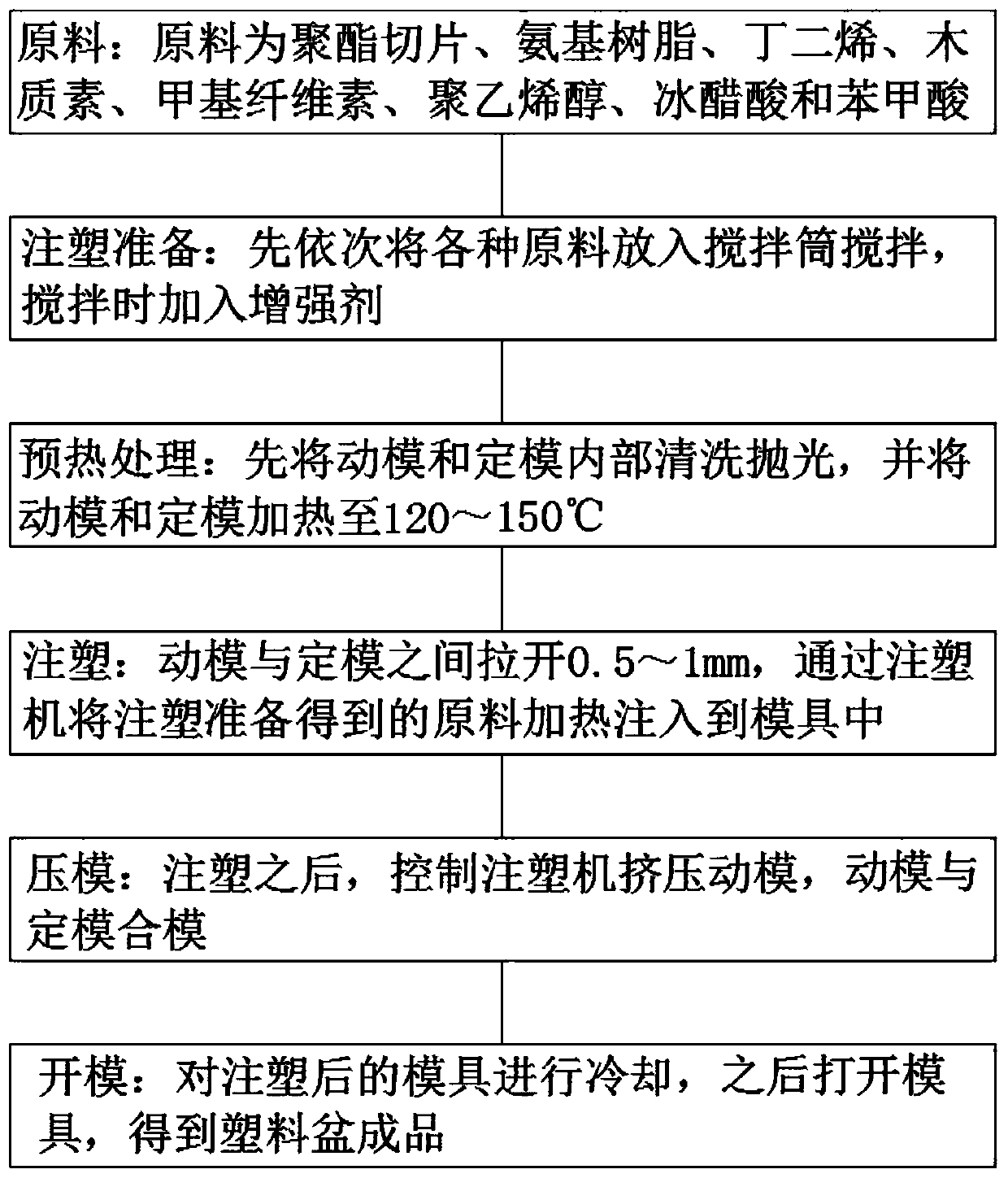

[0030] Such as figure 1 shown, including the following steps:

[0031] (1), raw material: raw material is polyester chips 32 parts, amino resin 5 parts, butadiene 3 parts, lignin part, methyl cellulose 1 part, polyvinyl alcohol 11 parts, glacial acetic acid 9 parts by weight parts and 7 parts of benzoic acid;

[0032] (2) Preparation for injection molding: First put polyester chips, amino resin, butadiene, lignin and methylcellulose into the mixing drum and stir in turn. Acetic acid and benzoic acid are put into glass dish, and use glass rod to stir, stir to obtain, stirring comprises the following steps:

[0033] (2.1), the first stage: when adding polyester chips, amino resin and butadiene, stir at a stirring speed of 130r / min;

[0034] (2.2), the second stage: adding lignin, stirring at a stirring speed of 190r / min;

[0035] (2.3), the third stage: add methyl cellulose, stir with the stirring speed of 55r / min;

[0036] (3) Preheating treatment: first clean and polish t...

Embodiment 2

[0041] Such as figure 1 shown, including the following steps:

[0042] (1), raw material: raw material is polyester chips 32 parts, amino resin 5 parts, butadiene 3 parts, lignin part, methyl cellulose 1 part, polyvinyl alcohol 11 parts, glacial acetic acid 9 parts by weight parts and 7 parts of benzoic acid;

[0043] (2) Preparation for injection molding: First put polyester chips, amino resin, butadiene, lignin and methylcellulose into the mixing drum and stir in turn. Acetic acid and benzoic acid are put into glass dish, and use glass rod to stir, stir to obtain, stirring comprises the following steps:

[0044] (2.1), the first stage: when adding polyester chips, amino resin and butadiene, stir at a stirring speed of 130r / min;

[0045] (2.2), the second stage: adding lignin, stirring at a stirring speed of 190r / min;

[0046] (2.3), the third stage: add methyl cellulose, stir with the stirring speed of 55r / min;

[0047] (3) Preheating treatment: first clean and polish t...

Embodiment 3

[0052] Such as figure 1 shown, including the following steps:

[0053] (1), raw material: raw material is polyester chips 32 parts, amino resin 5 parts, butadiene 3 parts, lignin part, methyl cellulose 1 part, polyvinyl alcohol 11 parts, glacial acetic acid 9 parts by weight parts and 7 parts of benzoic acid;

[0054] (2) Preparation for injection molding: First put polyester chips, amino resin, butadiene, lignin and methylcellulose into the mixing drum and stir in turn. Acetic acid and benzoic acid are put into glass dish, and use glass rod to stir, stir to obtain, stirring comprises the following steps:

[0055] (2.1), the first stage: when adding polyester chips, amino resin and butadiene, stir at a stirring speed of 130r / min;

[0056] (2.2), the second stage: adding lignin, stirring at a stirring speed of 190r / min;

[0057] (2.3), the third stage: add methyl cellulose, stir with the stirring speed of 55r / min;

[0058](3) Preheating treatment: first clean and polish th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com