Steel ladle side-blowing powder-spraying molten steel refining device and method

A powder spraying and ladle technology, applied in the field of steel refining, can solve the problems of exposure to molten steel, production uncertainty, and reduced life of powder pipes, and achieve the effects of reducing labor intensity, increasing life, and reducing kinetic energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

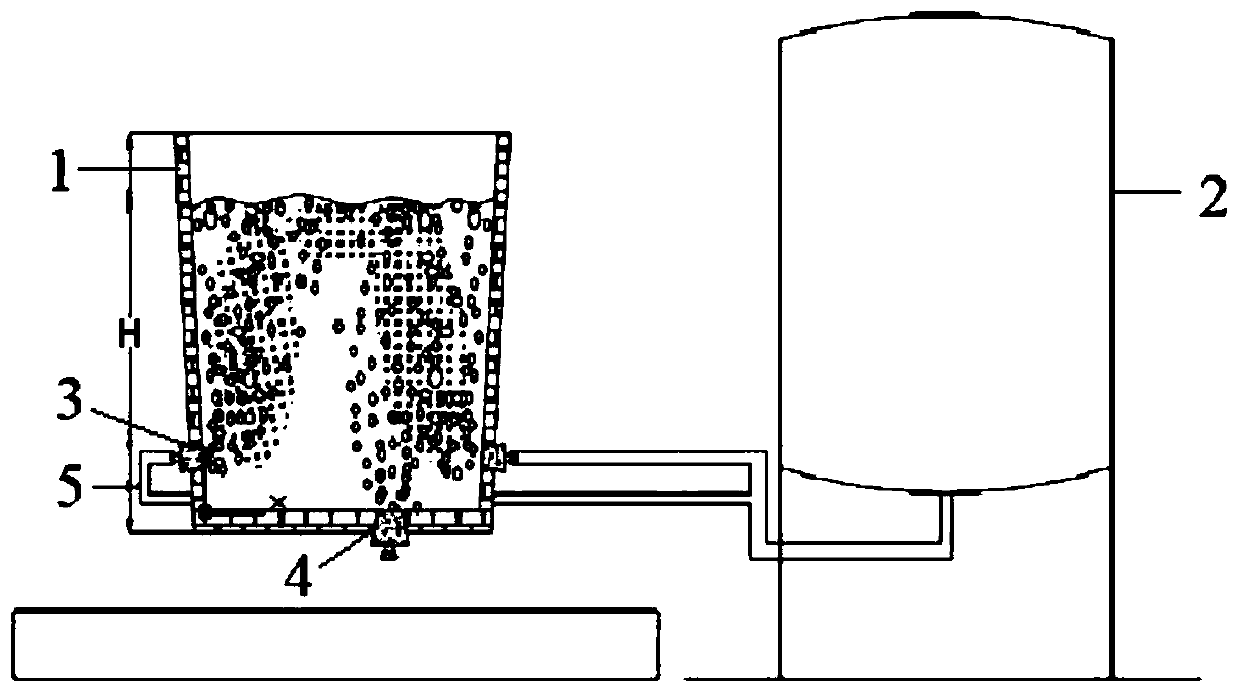

[0033] Such as figure 1 As shown, a ladle side blowing powder injection device for refining molten steel includes a ladle used for refining molten steel 1, a powder spraying tank used for powder spraying and air supply 2, used for injecting powder into the ladle 1 and The side-blown powder-spraying air-permeable brick 3 for gas and the bottom-blown air-permeable brick 4 for blowing and stirring molten steel. The ladle 1 includes the side wall of the ladle and the bottom of the ladle. The side-blown powder-injecting ventilating brick 3 is embedded in the side wall of the ladle, the bottom-blowing ventilating brick 4 is embedded in the bottom of the ladle, and the side-blowing powder-injecting ventilating brick 3 and the powder spraying tank 2 are sprayed The short tube 5 is connected.

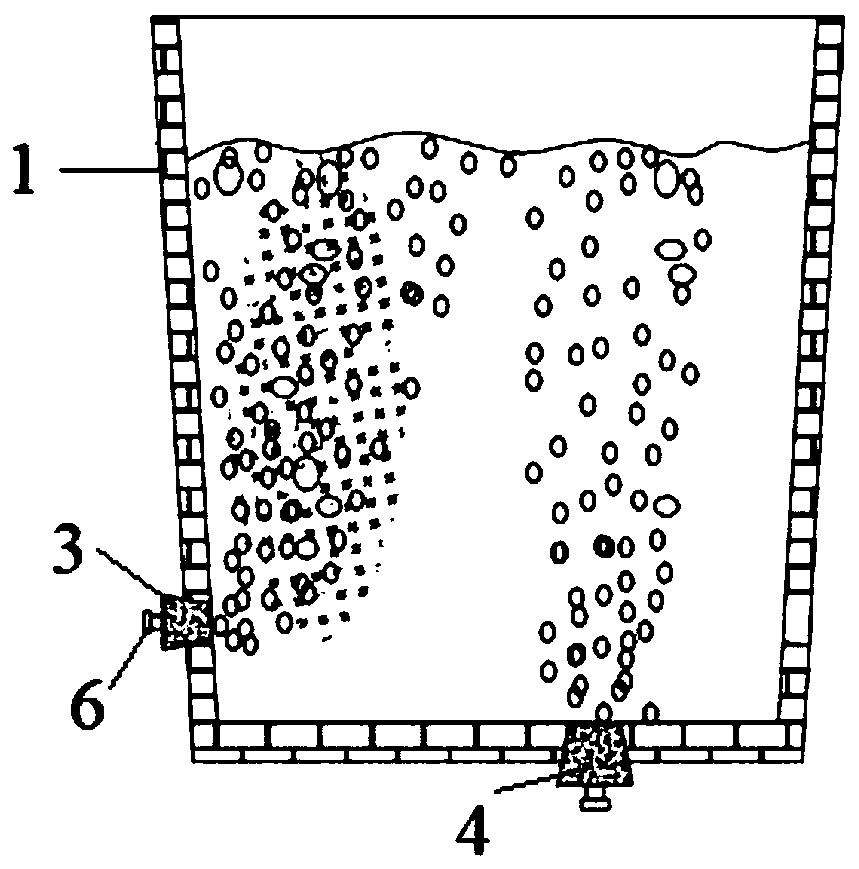

[0034] Such as figure 2 As shown, the device of this embodiment includes a side-blown powder-spraying air-permeable brick 3. The side-blown powder-injected air-permeable brick 3 is cylindrical, a...

Embodiment 2

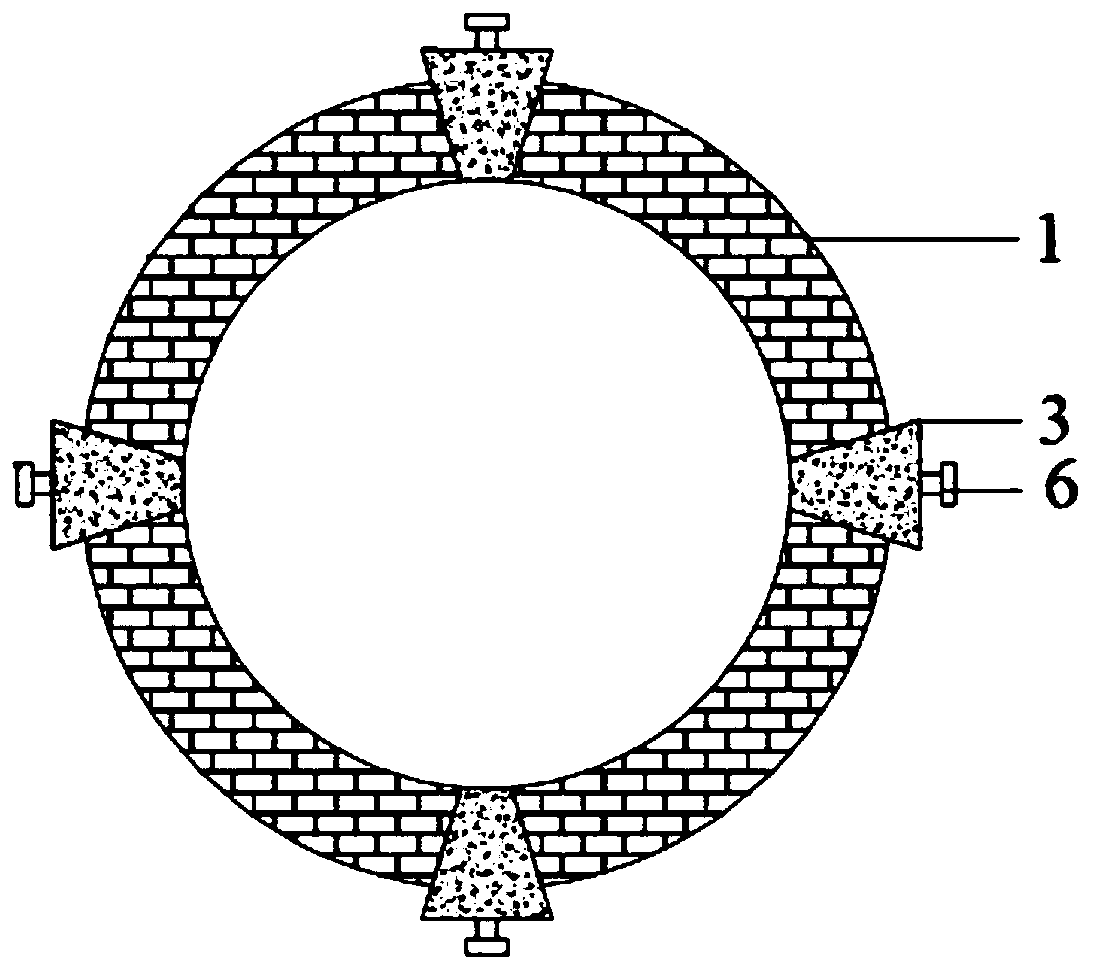

[0039] The difference between the ladle side blowing powder injection refining liquid steel device provided in this embodiment and the ladle side blowing powder injection refining liquid steel device provided in Example 1 is as follows: image 3 , 4 As shown, four side-blown powder-injected air-permeable bricks 3 are evenly embedded on the side wall of the ladle, and the side-blown powder-injected air-permeable brick 3 is in the shape of a truncated cone, and the upper mouth diameter of the circular cone is 120 mm. Such as Figure 5 As shown, each side-blown powder-injected air-permeable brick 3 includes pores 7 radially distributed on the side-blown powder-injected air-permeable brick 3, a total of 40 channels, each having a diameter of 0.2 mm. Preferably, the channel 7 can be divided into an inner channel and an outer channel according to the position relationship, the length of the inner channel is 40 mm, and the length of the outer channel is 50 mm.

[0040] In this embodimen...

Embodiment 3

[0042] The difference between the ladle side blowing powder injection refining molten steel device provided in this embodiment and the ladle side blowing powder injection refining molten steel device provided in Example 1 is that six side blowing powder injection devices are evenly embedded on the side wall of the ladle Breathable bricks, and the side-blown powder sprayed bricks are square. Each side-blown powder-injected air-permeable brick includes holes radially distributed on the side-blown powder-injected air-permeable brick. There are 10 holes in total, and the diameter of each hole is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com