A high-performance formaldehyde-free wood grain paper impregnation glue and its preparation method

A technology of wood grain paper and formaldehyde, applied in papermaking, paper, textiles and papermaking, etc., can solve the problems of environmental protection, performance and defects of melamine-impregnated film paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

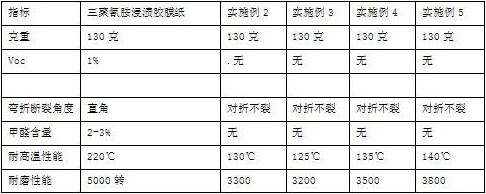

Examples

Embodiment 1

[0019] A high-performance formaldehyde-free impregnating glue for wood grain paper, comprising the following components in parts by mass: 50-70 parts of water-based 3-hydroxyacrylic acid emulsion, 3-5 parts of water-based epoxy resin, 10-20 parts of water-based amino resin, and water-based 3-5 parts of isocyanate crosslinking agent, 1-2 parts of water-based zirconia dispersion, 1-2 parts of water-based polytetrafluoroethylene dispersion, 3-5 parts of medium molecular weight methylsiloxane dispersion, 20-20 parts of deionized water 30 copies;

[0020] A preparation method for impregnating glue for high-performance formaldehyde-free wood grain paper, comprising the steps of:

[0021] Step 1: Mix the water-based zirconia dispersion, water-based polytetrafluoroethylene dispersion, and medium-molecular-weight methylsiloxane dispersion according to the above-mentioned component ratios, then add them to the water-based epoxy resin, stir at high speed for 5-8 minutes, and The rotatio...

Embodiment 2

[0025] A high-performance formaldehyde-free impregnating glue for wood grain paper, comprising the following components in parts by mass: 50 parts of water-based 3-hydroxyacrylic acid emulsion, 3 parts of water-based epoxy resin, 10 parts of water-based amino resin, and 3 parts of water-based isocyanate crosslinking agent , 1 part of water-based zirconia dispersion, 1 part of water-based polytetrafluoroethylene dispersion, 3 parts of medium molecular weight methylsiloxane dispersion, 20 parts of deionized water;

[0026] A preparation method for impregnating glue for high-performance formaldehyde-free wood grain paper, comprising the steps of:

[0027] Step 1: Mix the water-based zirconia dispersion, the water-based polytetrafluoroethylene dispersion, and the medium-molecular-weight methylsiloxane dispersion according to the above-mentioned component ratios, then add them to the water-based epoxy resin, stir at high speed for 6 minutes, and rotate at a speed of 600 rpm; at the...

Embodiment 3

[0031] A high-performance formaldehyde-free impregnating glue for wood grain paper, comprising the following components in parts by mass: 70 parts of water-based 3-hydroxyacrylic acid emulsion, 3 parts of water-based epoxy resin, 10 parts of water-based amino resin, and 3 parts of water-based isocyanate crosslinking agent , 1 part of water-based zirconia dispersion, 1 part of water-based polytetrafluoroethylene dispersion, 3 parts of medium molecular weight methylsiloxane dispersion, 20 parts of deionized water;

[0032] A preparation method for impregnating glue for high-performance formaldehyde-free wood grain paper, comprising the steps of:

[0033] Step 1: Mix the water-based zirconia dispersion, the water-based polytetrafluoroethylene dispersion, and the medium-molecular-weight methylsiloxane dispersion according to the above-mentioned component ratios, then add them to the water-based epoxy resin, stir at high speed for 6 minutes, and rotate at a speed of 600 rpm; at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com