Cleaning device for columnar supporting part of above water drilling platform

A drilling platform and cleaning device technology, which is applied in the fields of petroleum engineering drilling and foundation engineering drilling, and can solve the problems of corrosion of support parts, potential safety hazards, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

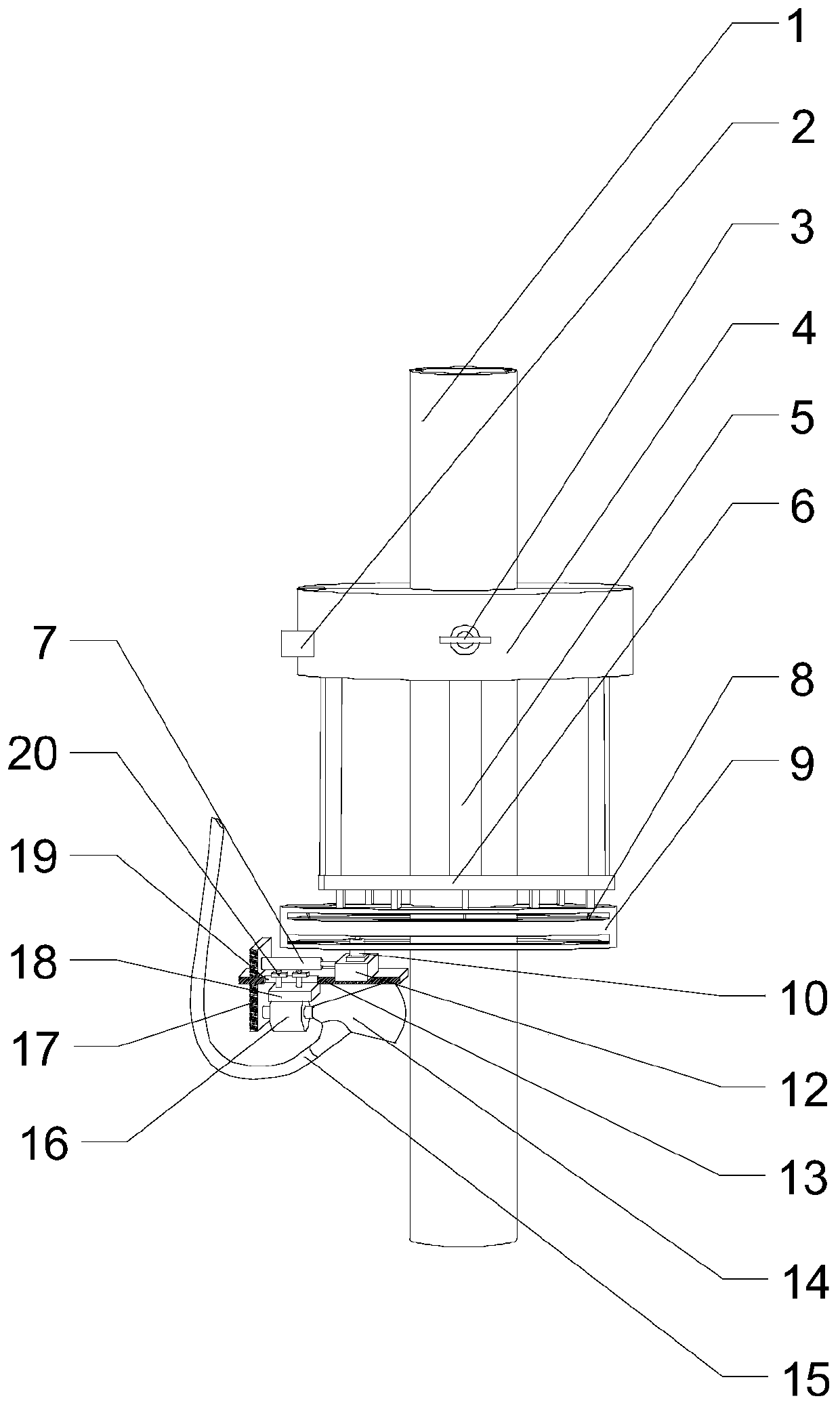

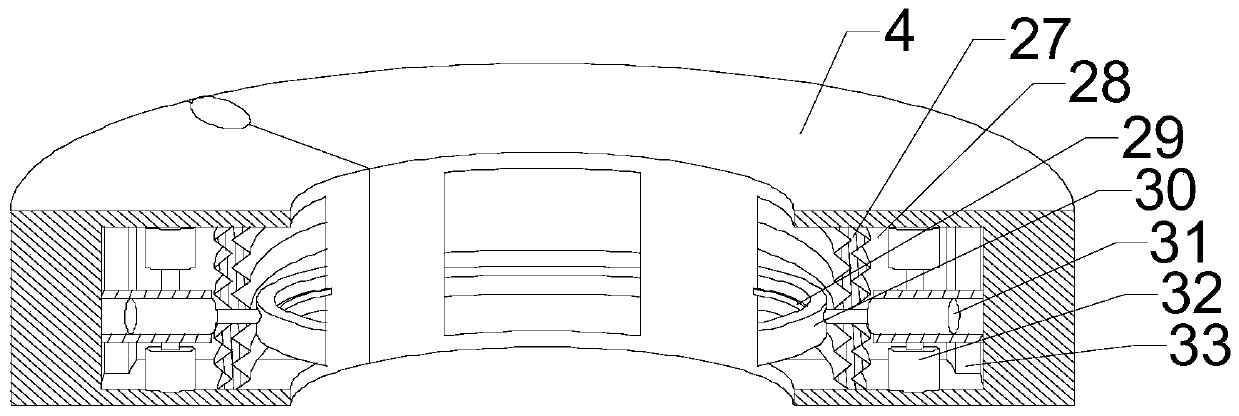

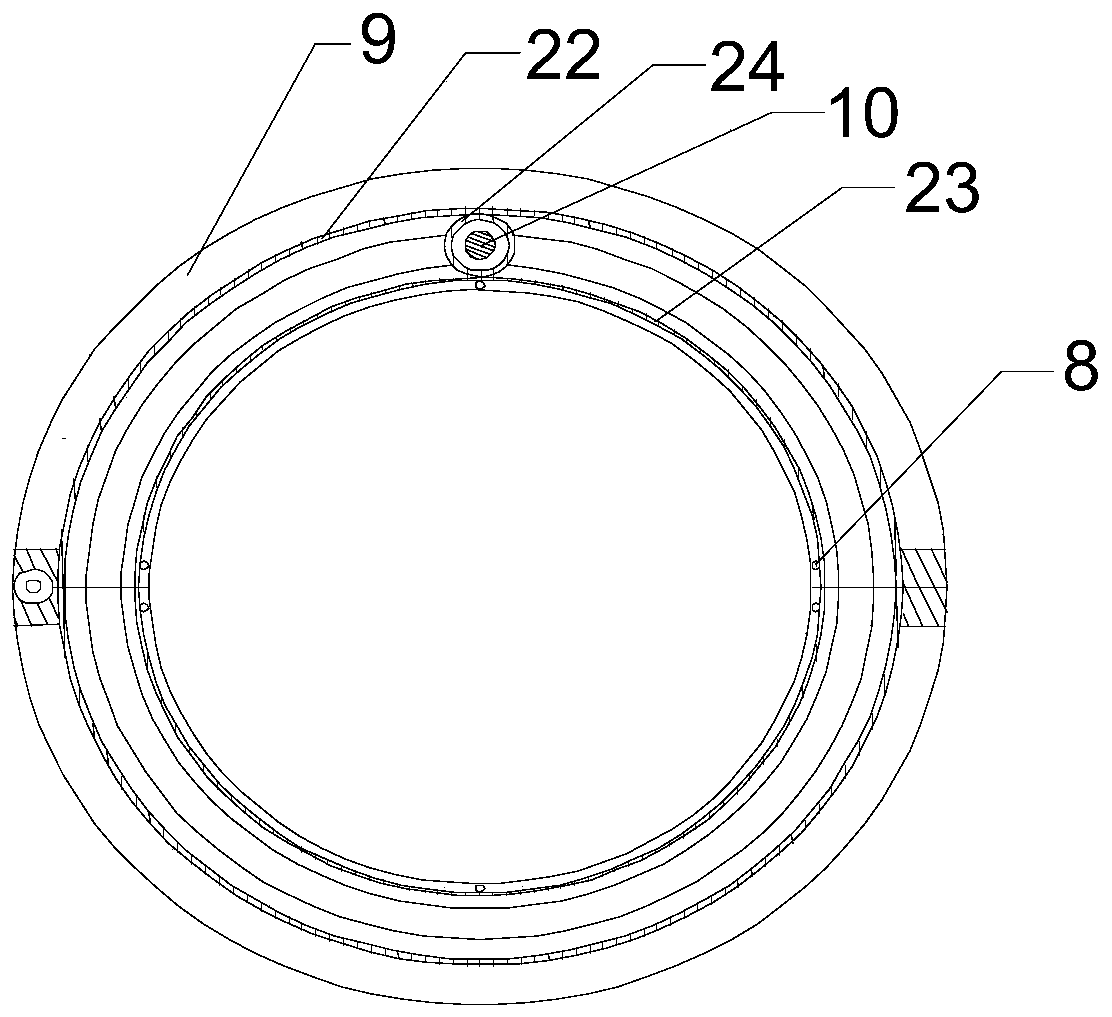

[0030] Such as Figure 1-5 As shown, this embodiment includes clamping units sleeved on the outer peripheral wall of the support 1, and each clamping unit includes a semicircular traveling cylinder 4 and an orbital ring 9, and the orbital ring 9 is fixed on the traveling cylinder 4 The lower end surface of the track ring 9 is provided with a semicircular flange on its inner peripheral wall along the circumferential direction of the orbit ring 9. An external toothed belt 22 is installed on the upper end surface of the flange. Circular inner ring, and the radius of the circle corresponding to the inner ring is smaller than the radius of the circle corresponding to the flange, an inner toothed belt 23 is provided on the upper surface of the inner ring, and a support seat 12 is provided under the track ring 9, and the rotating motor 10 is arranged on the supporting seat 12, the output end of the rotating electrical machine 10 extends upwards after passing through the gap between t...

Embodiment 2

[0037] Such as Figure 1~3 As shown, in this embodiment, on the basis of Embodiment 1, a guide groove 33 perpendicular to the axis of the support member 1 is formed on the inner wall of each arc-shaped groove 28, and the end of the rectangular cylinder is slidably arranged In the guide groove 33; on the inner peripheral wall of each snap ring 30, a matching arc-shaped rubber corrugated strip 29 is provided; on the lower end surface of each traveling cylinder 4, a plurality of support rods are provided 5. The semicircular bottom ring 6 is connected to the lower ends of a plurality of support rods 5, the upper end surface of the track ring 9 is connected to the bottom ring 6 through a connecting rod, and a semicircular fixing ring is provided on the outer wall of the connecting rod , the inner ring is connected with the fixed ring through the connecting rod 8 .

[0038] In this embodiment, during the linear movement of the lifting unit, the rectangular cylinder in the arc-shape...

Embodiment 3

[0042] Such as Figure 1-5 Shown, present embodiment is on the basis of embodiment 2, and described cleaning assembly comprises movable plate 13, vertical plate 17 and hanging plate 18, is fixed with propelling cylinder 21 on the side wall of vertical plate 17, and propelling cylinder 21 The output end is connected with the supporting seat 12, and a through hole is opened in the middle part of the vertical plate 17, and one end of the movable plate 13 extends outward after moving through the through hole, and the other end of the movable plate 13 faces the support member 1, and the The lower surface of the supporting seat 12 is connected with the upper surface of the movable plate 13, a rectangular hole 19 is provided on the movable plate 13, and at least one strut is provided at the bottom of the propelling cylinder 21, and the clamping plate 7 is installed on the strut, and the clamping plate 7 Place on the upper surface of the movable plate 13 and the width of the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com