Novel noise reduction worm tongue structure for centrifugation

A volute tongue and a new type of technology are applied in the field of new noise reduction volute and tongue structures for centrifugal use, which can solve the problems of structural improvement of the outer layer and inner layer, limited noise reduction effect of centrifugal fans, and high manufacturing cost, and achieve uniform pressure and reduce The effect of pressure pulsation, reduction of rotating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

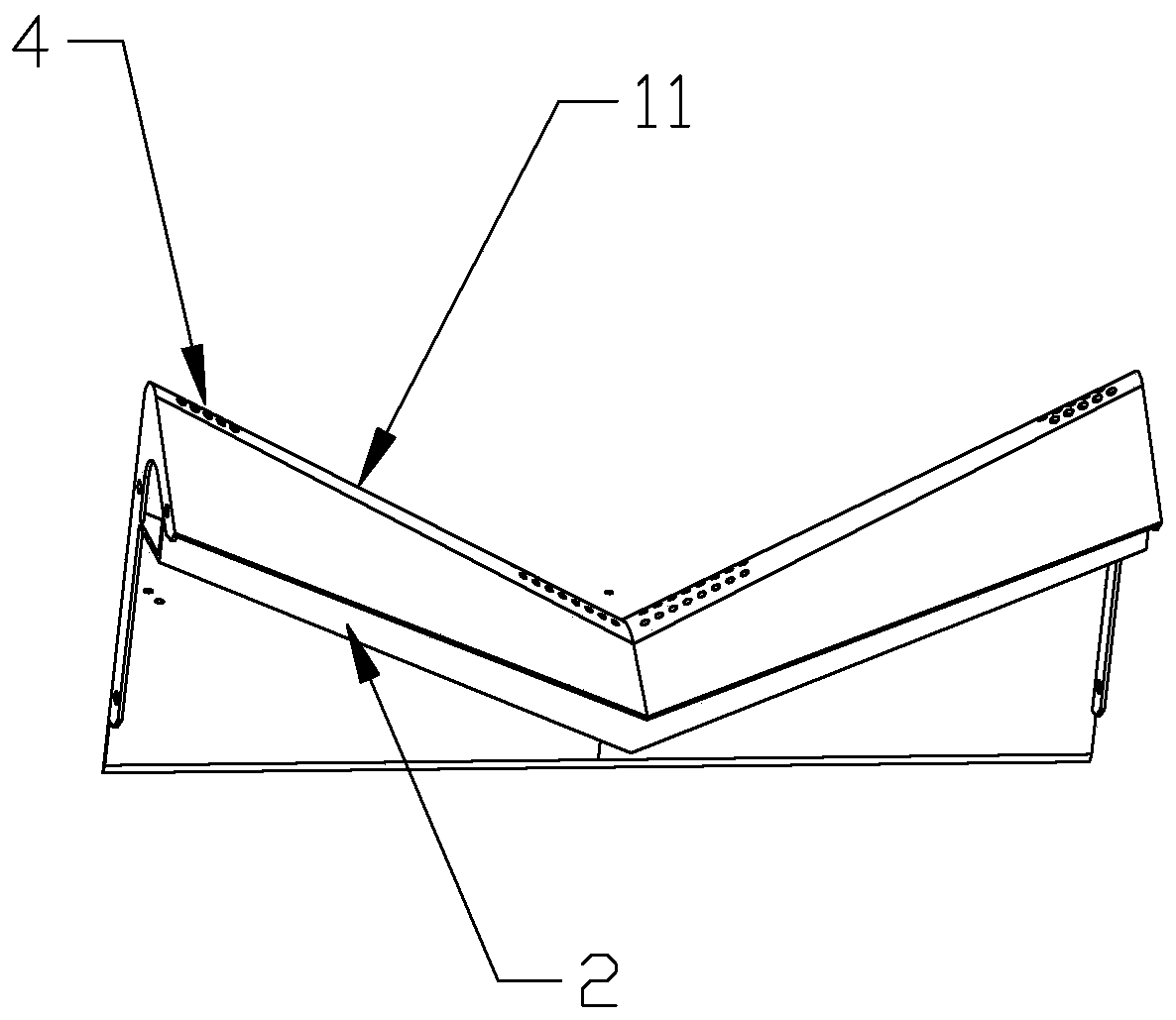

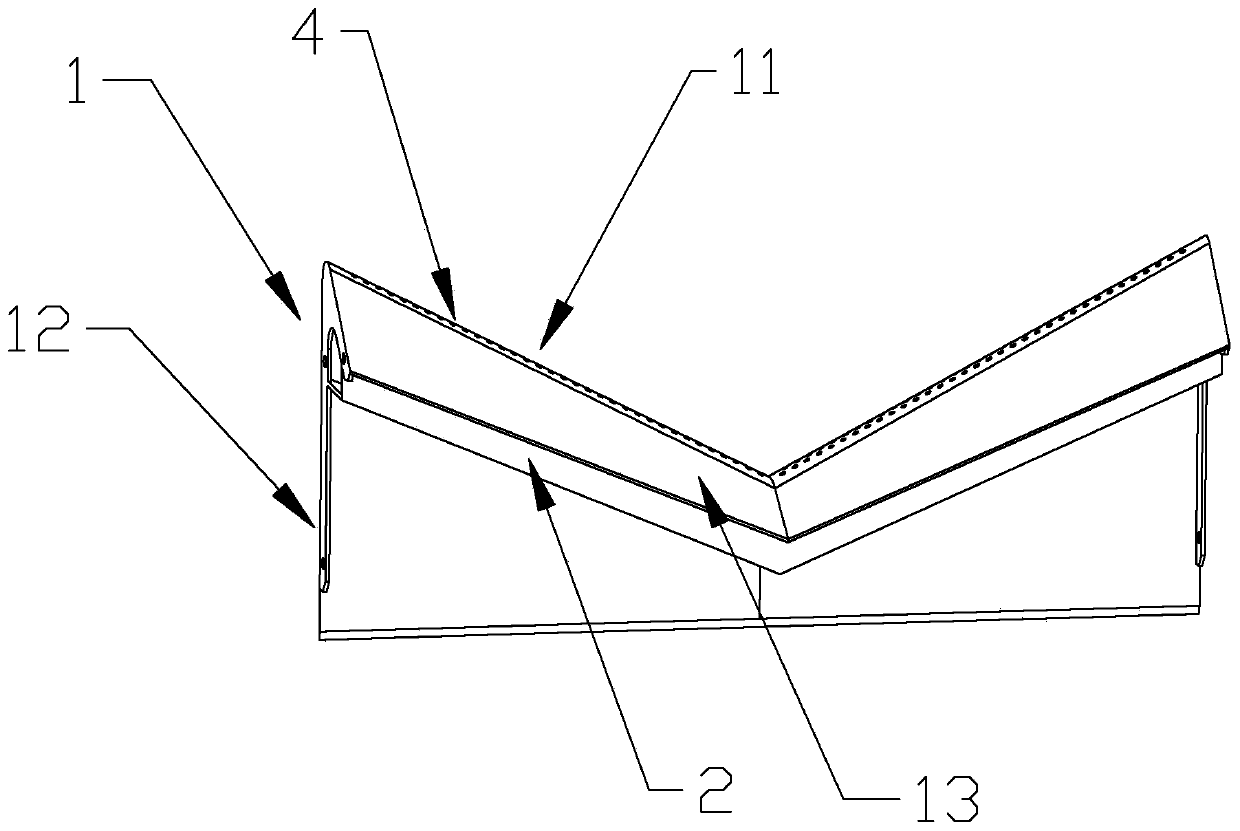

[0050] Such as figure 2 As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. In this embodiment, the through-holes 4 are distributed continuously and equidistantly from the left end to the right end of the bent portion 1 . The position and shape of the through hole 4 are designed differently according to different fans. The design is combined with the gas flow conditions near the volute tongue and the shape of the cavity to optimize the design. When the optimal design is obtained, the acoustic performance of the fan will be the best. aerodynamic performance.

Embodiment 3

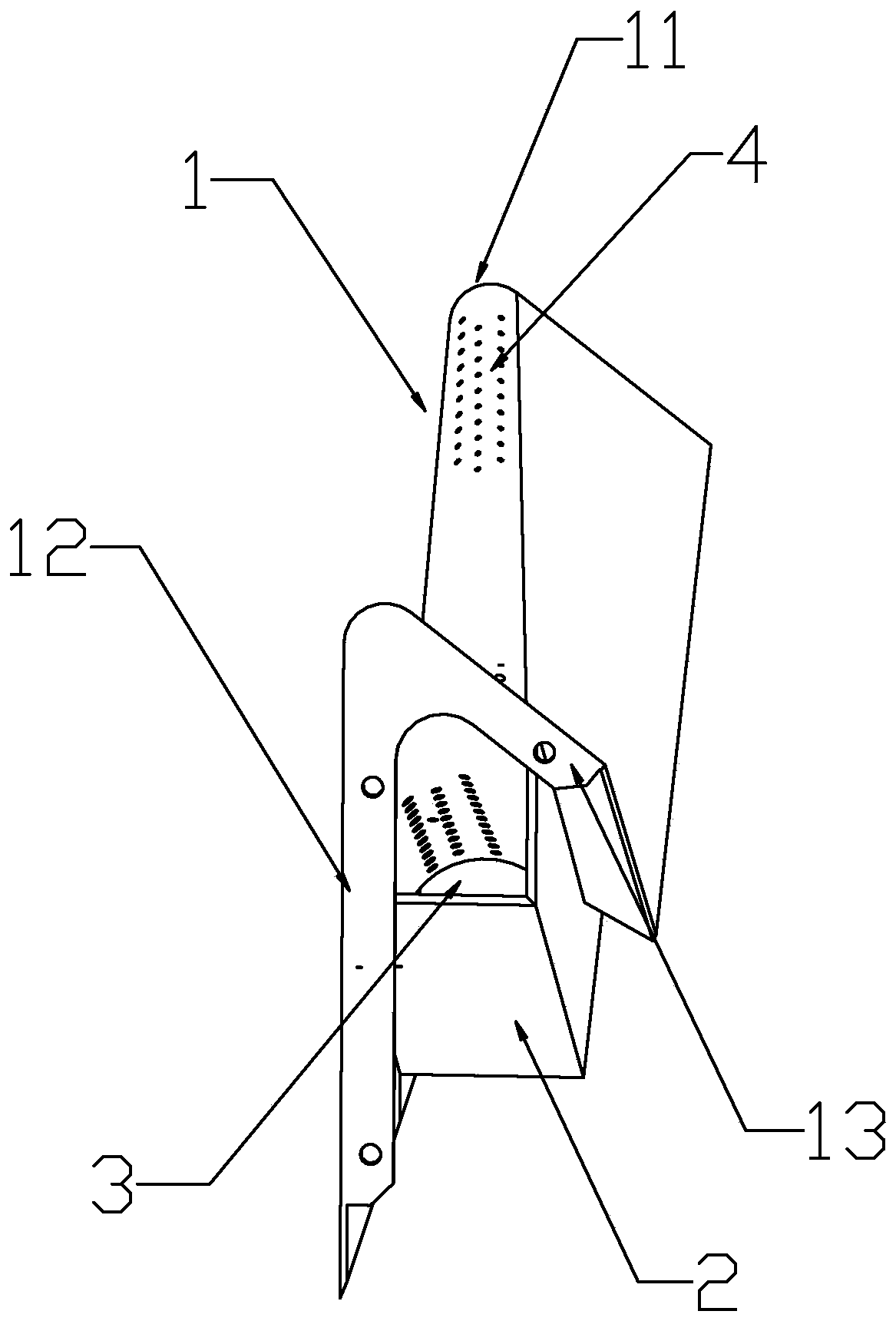

[0052] Such as Figure 4 As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. In this embodiment, the bottom of the cavity wall 2 is a corrugated structure 21 , and the corrugated structure 21 includes several crests and troughs arranged along the direction from the left end to the right end of the cavity wall 2 . When the air flow from the impeller flows to the position near the volute tongue, part of the air flow enters the cavity structure 3 from the through hole on the high pressure side of the volute tongue. After the air flow flows in the cavity structure 3 with a wave-shaped bottom, 3. The through holes on the low pressure side of the volute tongue on both sides flow out, and the wave-shaped cavity regulates the air intake state of the through hole 4 to a certain extent. The volute tongue with the through hole 4 absorbs part of the gas in the vicinity of the volute...

Embodiment 4

[0054] Such as Figure 5 As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. In this embodiment, the volute tongue structure is a flat tongue structure, and the bending part 1 of the flat tongue structure extends in a straight line from the left end to the right end, and the bending part 1 of the flat tongue structure is from the left end to the right end. Horizontal or inclined in one direction, the cavity wall 2 is a horizontal bottom wall or a bent wall, and the two end surfaces of the bent wall along the width direction are connected to the inner surface of the bent part 1 . The direction from left to right is the length direction of the bent wall, and the direction perpendicular to the length direction is the width direction. The horizontal bottom wall or the bottom of the bent wall is a wave-shaped structure or a horizontal structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com