Device and method for operating variable speed work device

A technology of working equipment and speed, which is applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., can solve problems such as increased investment requirements, limitations in application fields, and decreased efficiency of speed/power control, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

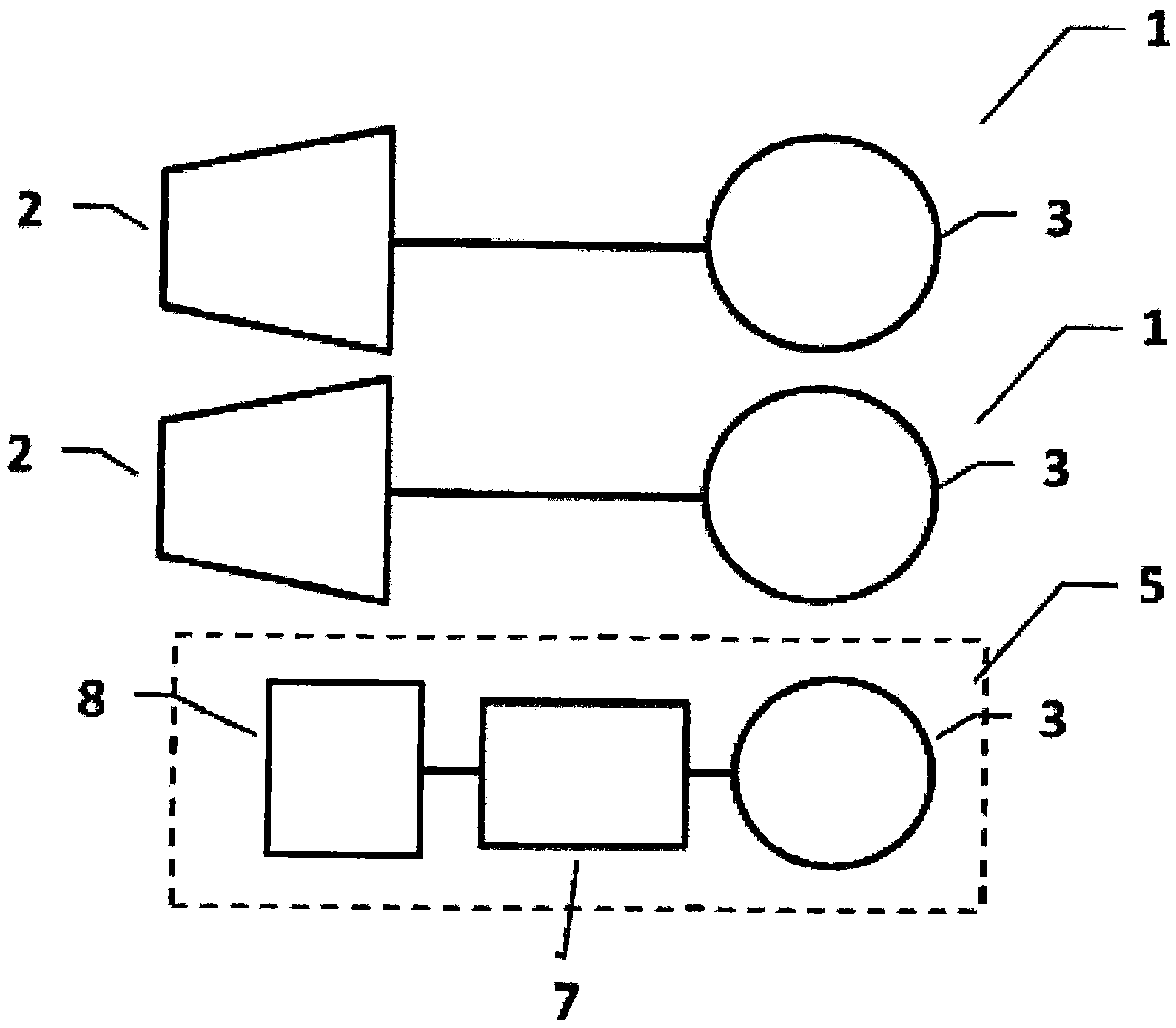

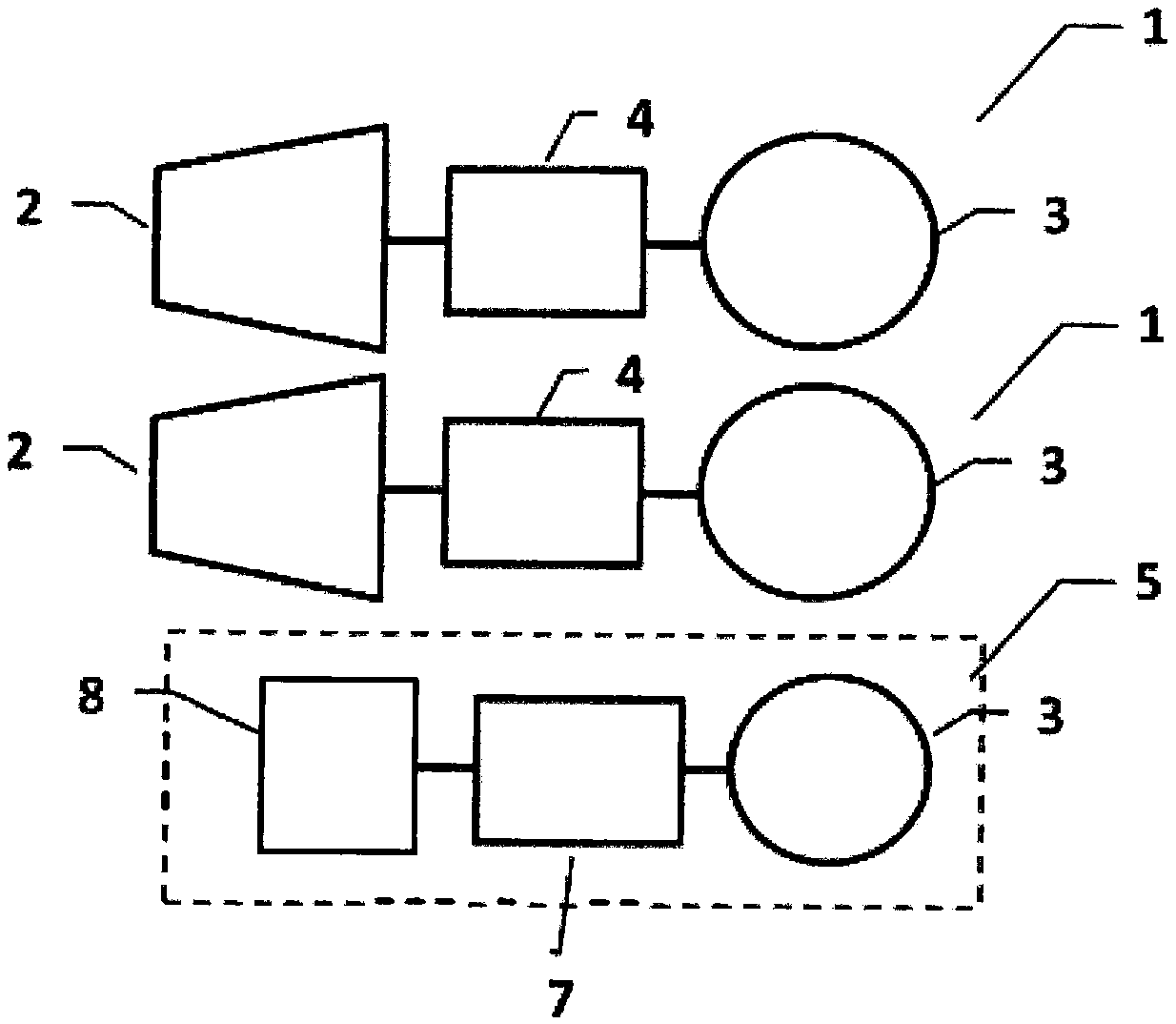

[0032] figure 1 and figure 2 The diagram shown illustrates the prior art, such as in a power plant, with two drive trains 1 that are in figure 1 Include a driver 2 and a working device 3 in the shown embodiment, and in figure 2 In the exemplary embodiment shown, the drive train has a drive 2 , an associated gearbox 4 and a working device 3 . Both exemplary embodiments require a drive 8 as a motor, a working device 3 and a starting device 5 with a gearbox 7 . The gearbox 7 can be a gearbox with a constant transmission ratio, or a transmission control clutch, or a superposition transmission of a hydraulic converter with a variable transmission ratio. Based on a total power of 100%, the power distribution of the main drive train 1 is 50% each.

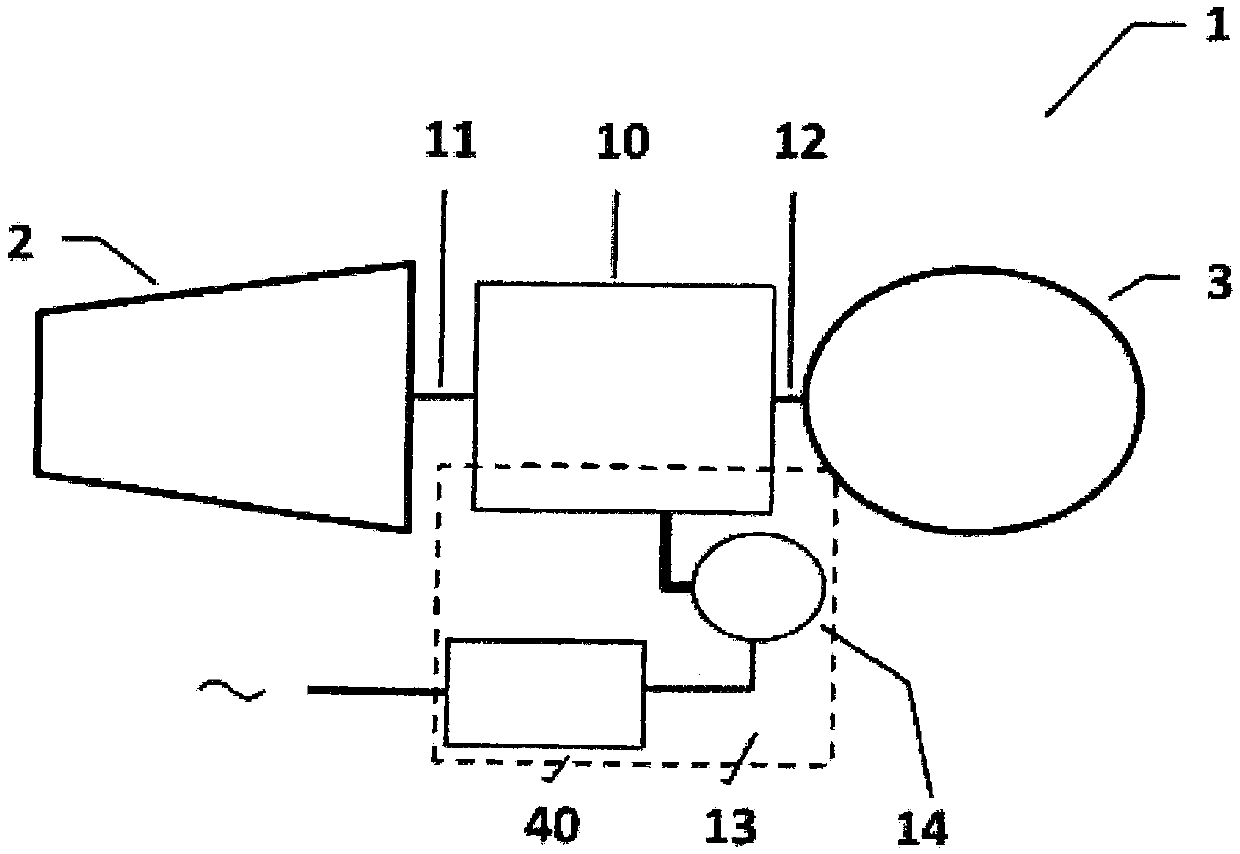

[0033] exist image 3 In, an arrangement of a drive train 1 according to the invention is illustrated, comprising a drive 2, a superposition transmission 10 with an input branch 11, an output branch 12 and a control branch 13 and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com