Semiconductor combustible gas sensor based on MEMS technology and preparation method thereof

A gas sensor and semiconductor technology, applied in the direction of air quality improvement, material resistance, etc., can solve the problems of increased energy consumption of gas sensors, difficulty in ensuring product consistency, increased heat loss, etc., to achieve simple and easy preparation process and avoid warping , increase the binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

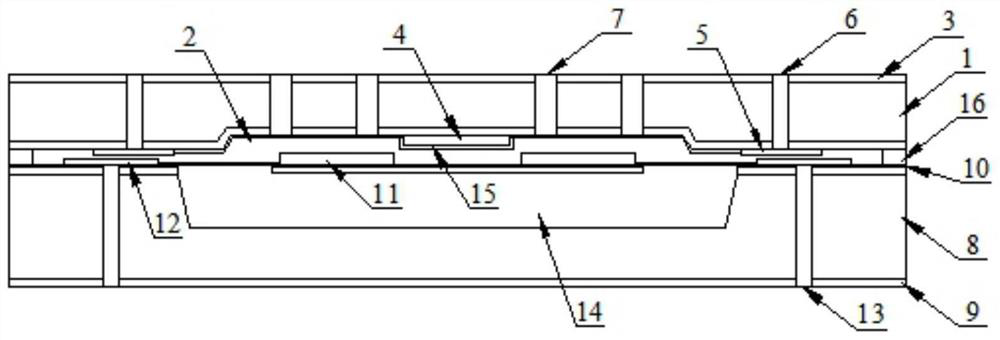

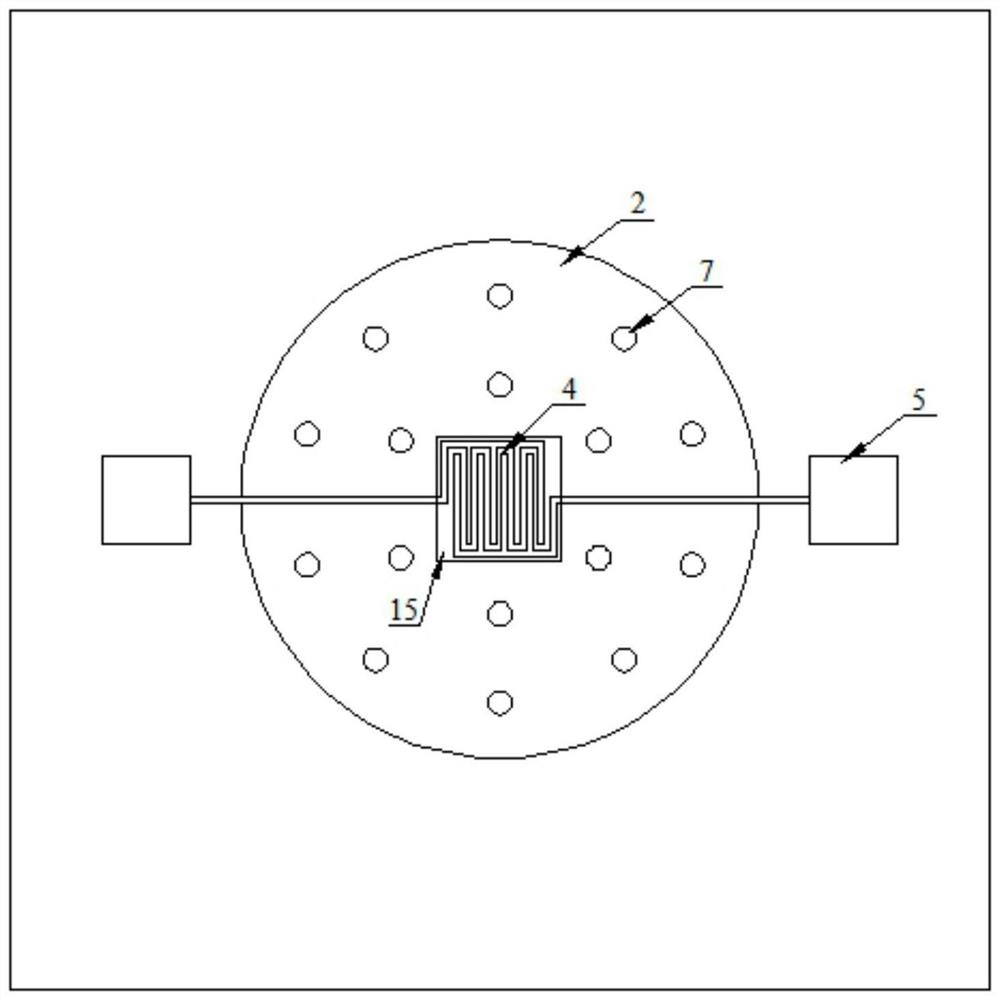

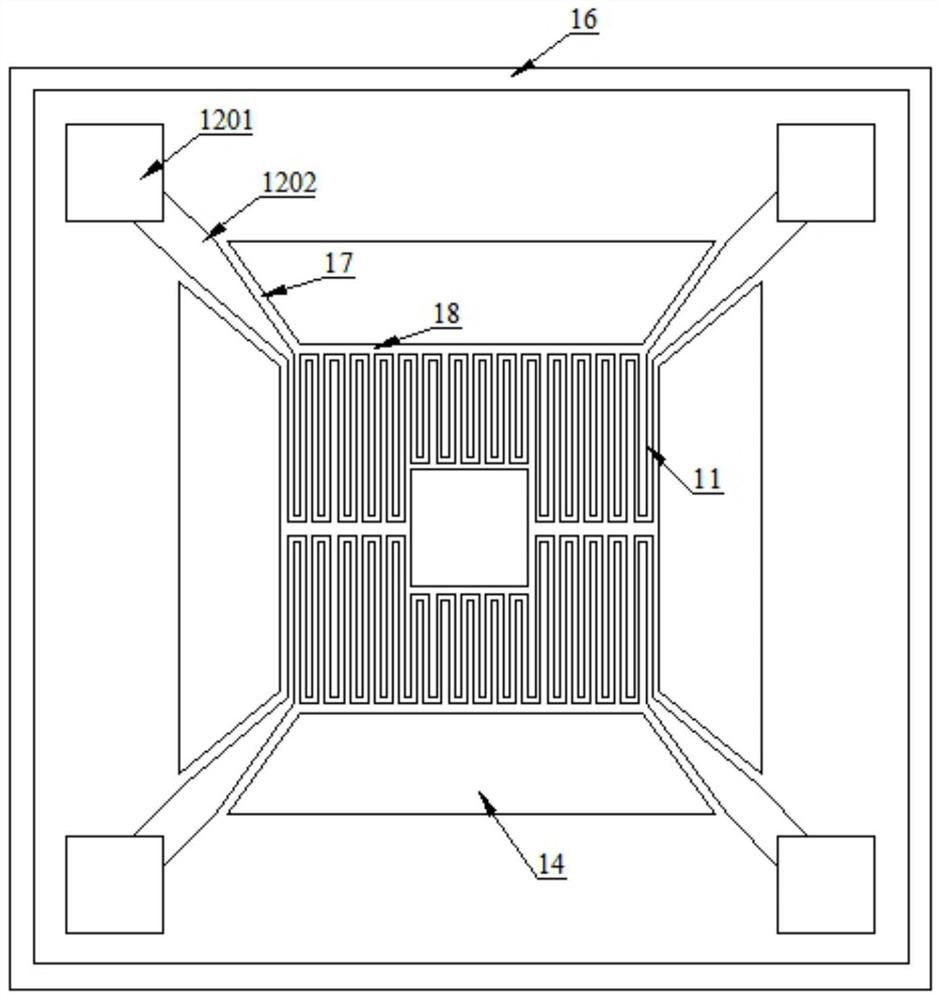

[0022] like Figures 1 to 3 As shown, a semiconductor combustible gas sensor based on MEMS technology includes a gas sensing module and a heating module arranged oppositely, and the gas sensing module and the heating module are bonded and connected. The outer edge of the upper surface of the heating module is provided with a gasket 16, and the gasket 16 is connected between the heating module and the gas sensing module.

[0023] The gas sensor module includes a silicon substrate 1, a groove 2 is provided on the lower side of the silicon substrate 1, and a first insulating layer 3 is formed on the upper and lower sides of the silicon substrate 1, and the first insulating layer on the lower side is formed. 3, a test electrode 4 and a test conductive strip 5 are sputtered on the test electrode 4, and a gas-sensitive coating 15 is coated on the test electrode 4, and the gas-sensitive coating 15 contains semiconductor metal oxides, precious metal catalysts, catalyst carriers and ac...

Embodiment 2

[0041] like Figure 5 As shown, since the test conductive strip 5 does not overlap with the heating electrode 11 and the heating conductive strip 12, the first lead hole 6 can be arranged on the heating module, and the test electrode 4 can pass the test conductive strip 5, the first lead Holes 6 are routed to the bottom surface of the heating module, which helps further facilitate sensor packaging.

[0042] The difference between Example 2 and Example 1 is that the gasket 16 is no longer arranged between the heating module and the gas sensor module, the depth of the groove 2 in the gas sensor module is increased to 40 μm, and the first A lead hole 6 , a first lead hole 6 is provided at the portion of the heating module corresponding to the end of the test conductive strip 5 .

Embodiment 3

[0044] According to the structure of the semiconductor combustible gas sensor described in Embodiment 1, in order to improve the consistency and stability of the gas-sensitive coating 15, the specific coating steps are as follows:

[0045] (a) Prepare the raw materials for the mixed slurry:

[0046] 180-220 parts of tin oxide, 72-88 parts of stannous sulfate, 3.6-4.4 parts of pickled asbestos, 45-55 parts of alumina, 6.7-8.3 parts of precious metal catalyst, 6.3-7.7 parts of tungsten trioxide, 3.0-3.8 parts of magnesium oxide parts, 2.7-3.3 parts of vanadium pentoxide, 1.4-1.8 parts of antimony pentoxide, 250-310 parts of tetraethyl silicate, 330-400 parts of formic acid, 100-125 parts of ethylene glycol, 135 parts of N-methylpyrrolidone ~170 parts, 140-175 parts anhydrous ethanol, 180-220 parts pure water;

[0047] This example adopts the optimal formula, specifically: 2.0g of tin oxide, 0.8g of stannous sulfate, 0.04g of pickled asbestos, 0.5g of alumina, 0.06g of platinum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com