Rice-planting machine

A technology of rice transplanter and fuselage, which is applied to seeder parts, control devices, agricultural vehicles, etc., and can solve problems such as stopping the fuselage, poor maintenance performance, and complicated assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiment of the invention

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

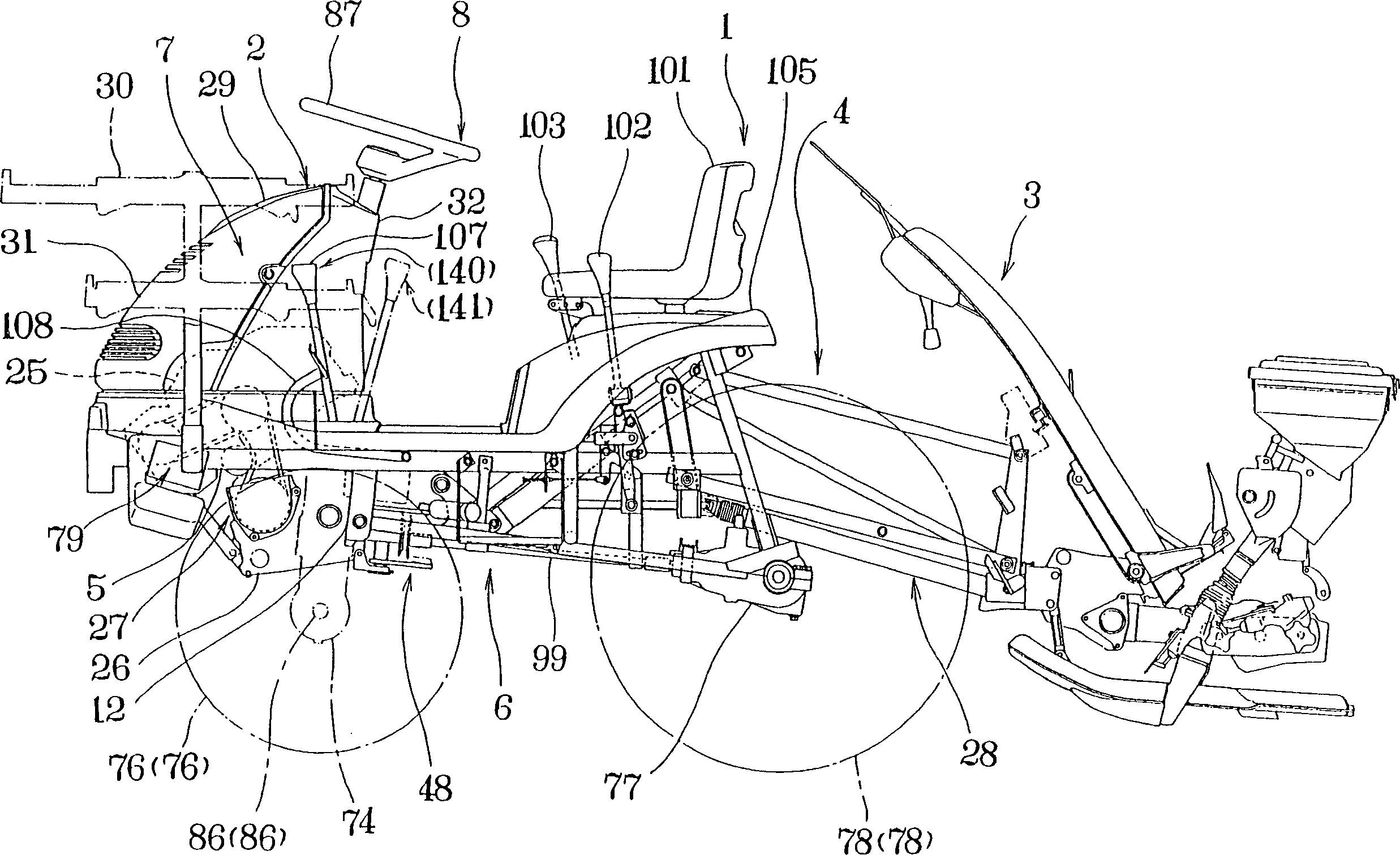

[0038] Riding rice transplanter 1 of the present invention is as figure 1 As shown, the transplanting machine 3 is connected and arranged on the rear portion of the traveling body 2 that can walk automatically by the lifting mechanism 4 in a liftable manner.

[0039] Walking fuselage 2 such as figure 1 Walking part 6 is arranged on the bottom of frame 5 as shown, on the other hand, it is arranged on the front side upper part of frame 5 with prime mover part 7, and operation control part 8 is arranged on the rear of prime mover part 7.

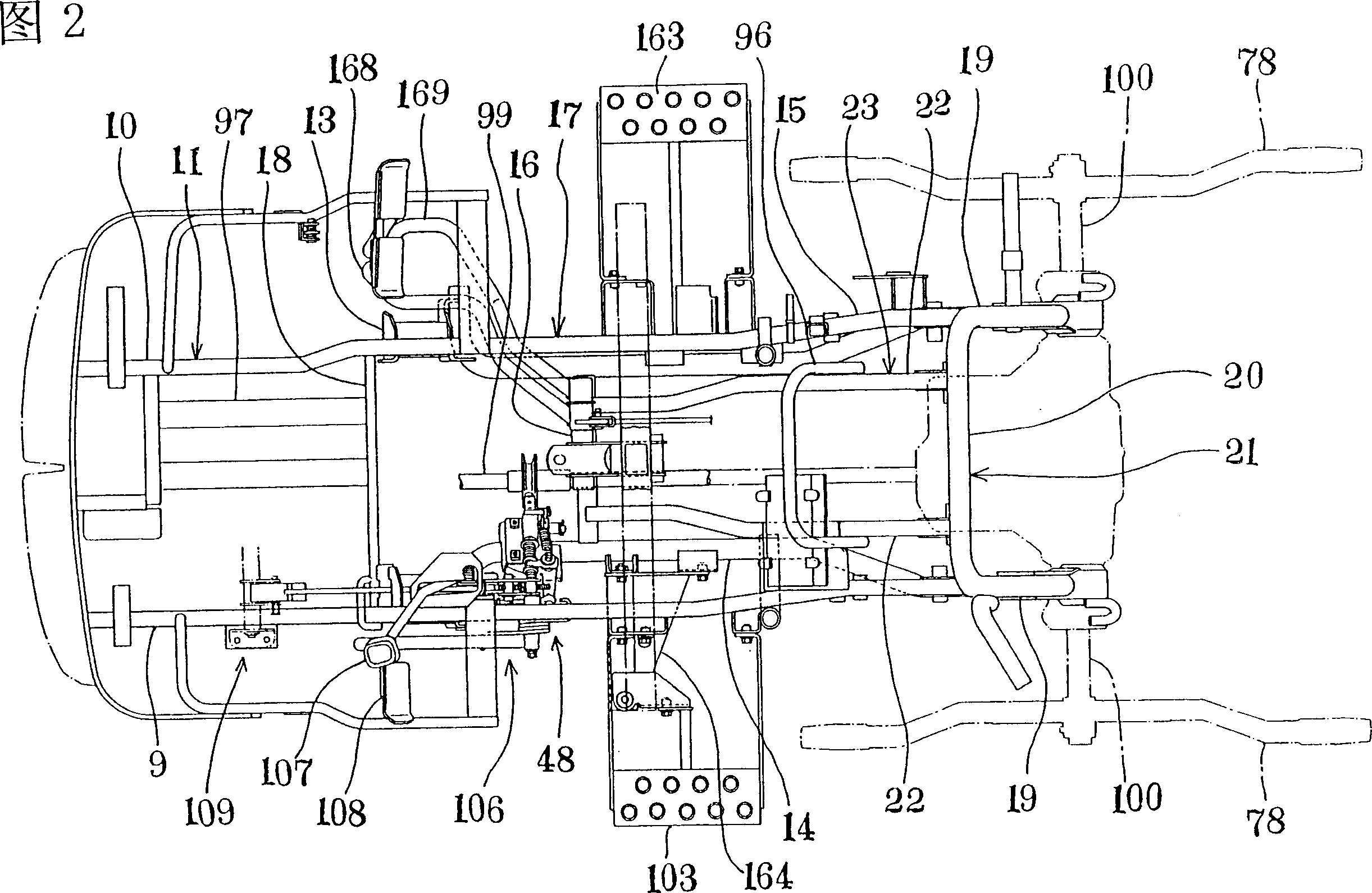

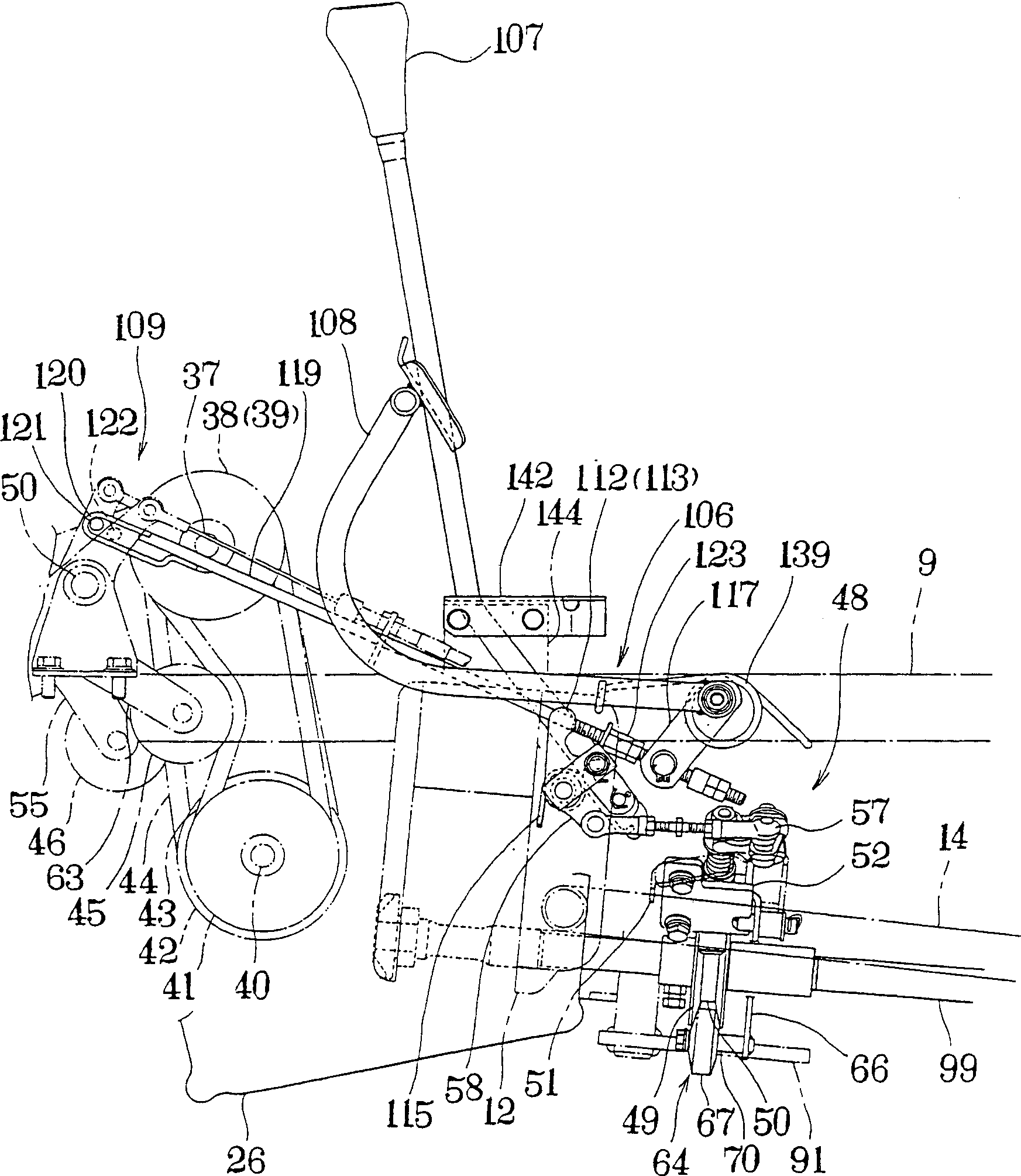

[0040] rack 5 as figure 1 As shown in , 2, a pair of rectangular cross-section main pipes 9,10 extending front and rear and a front pipe (not shown) that is erected between the front ends of the main pipes 9,10 and has a rectangular cross-section form a plane view. Become on the U-shaped main fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com