Method and system for calibrating gear position of electronic gear shifter

An electronic shifter and gear technology, which is applied to components with teeth, transmission control, belt/chain/gear, etc., can solve the problem of large impact noise between the shift lever and the base, and the electronic shifter cannot realize self-control Diagnosis and other problems to achieve the effect of improving accuracy, sensitivity, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

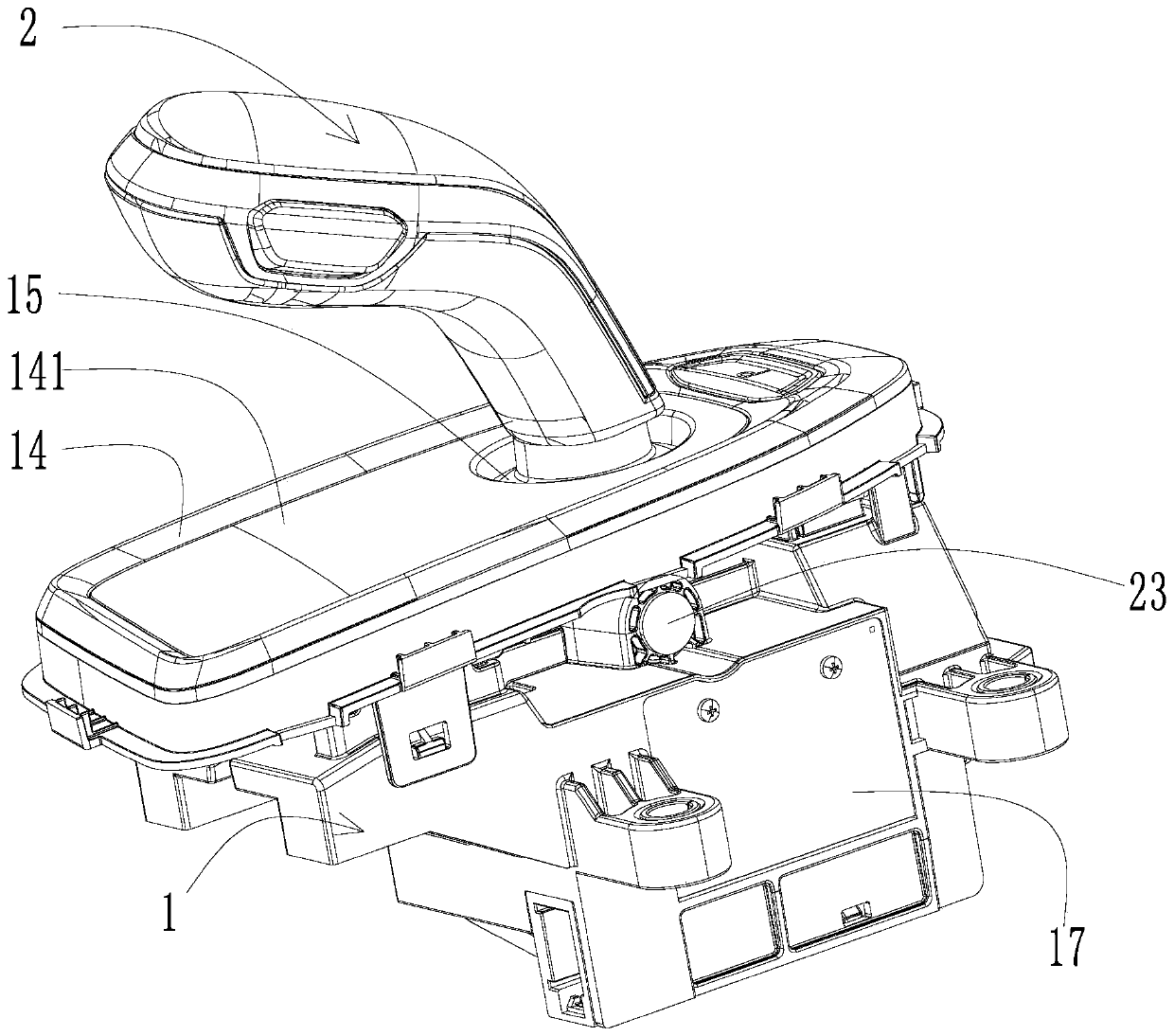

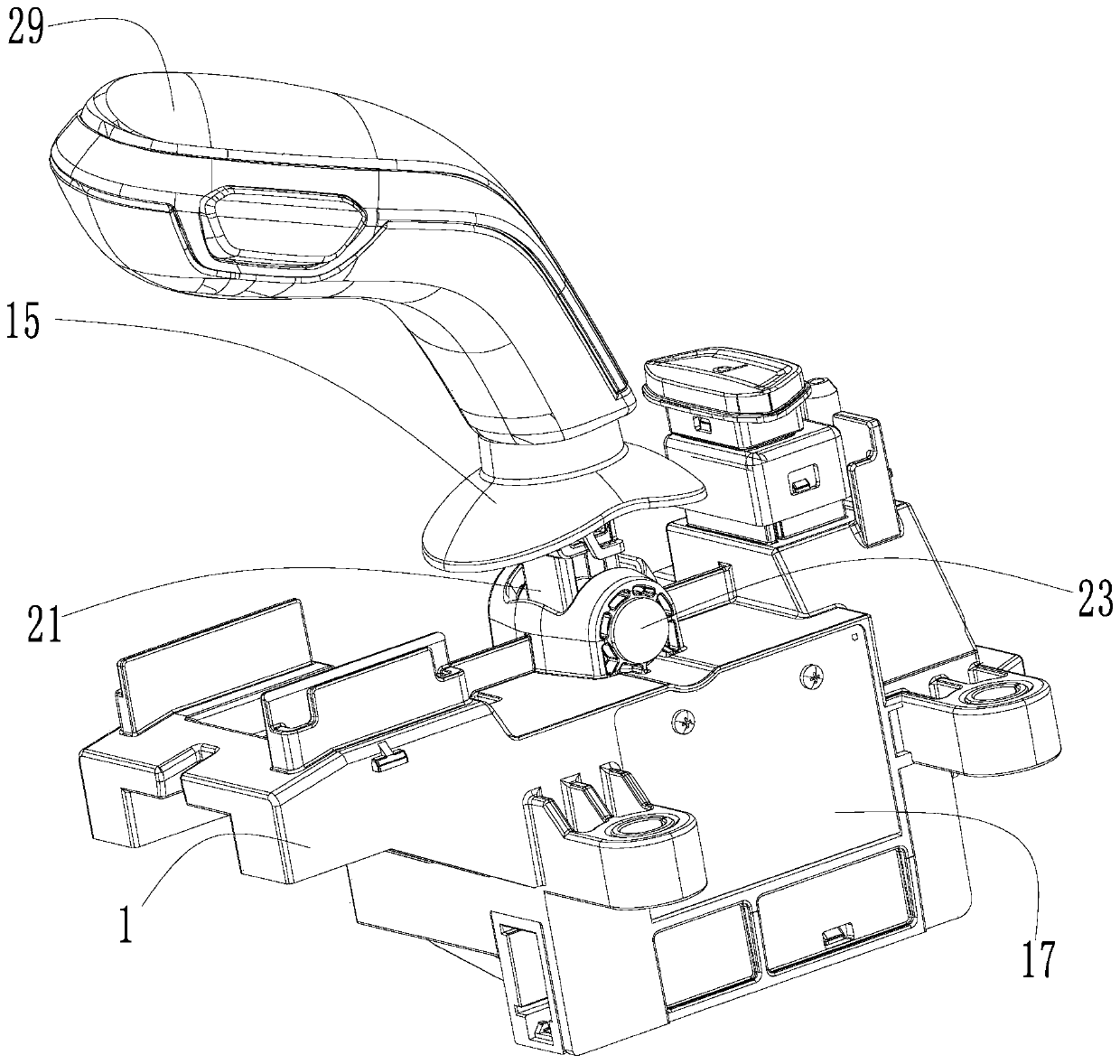

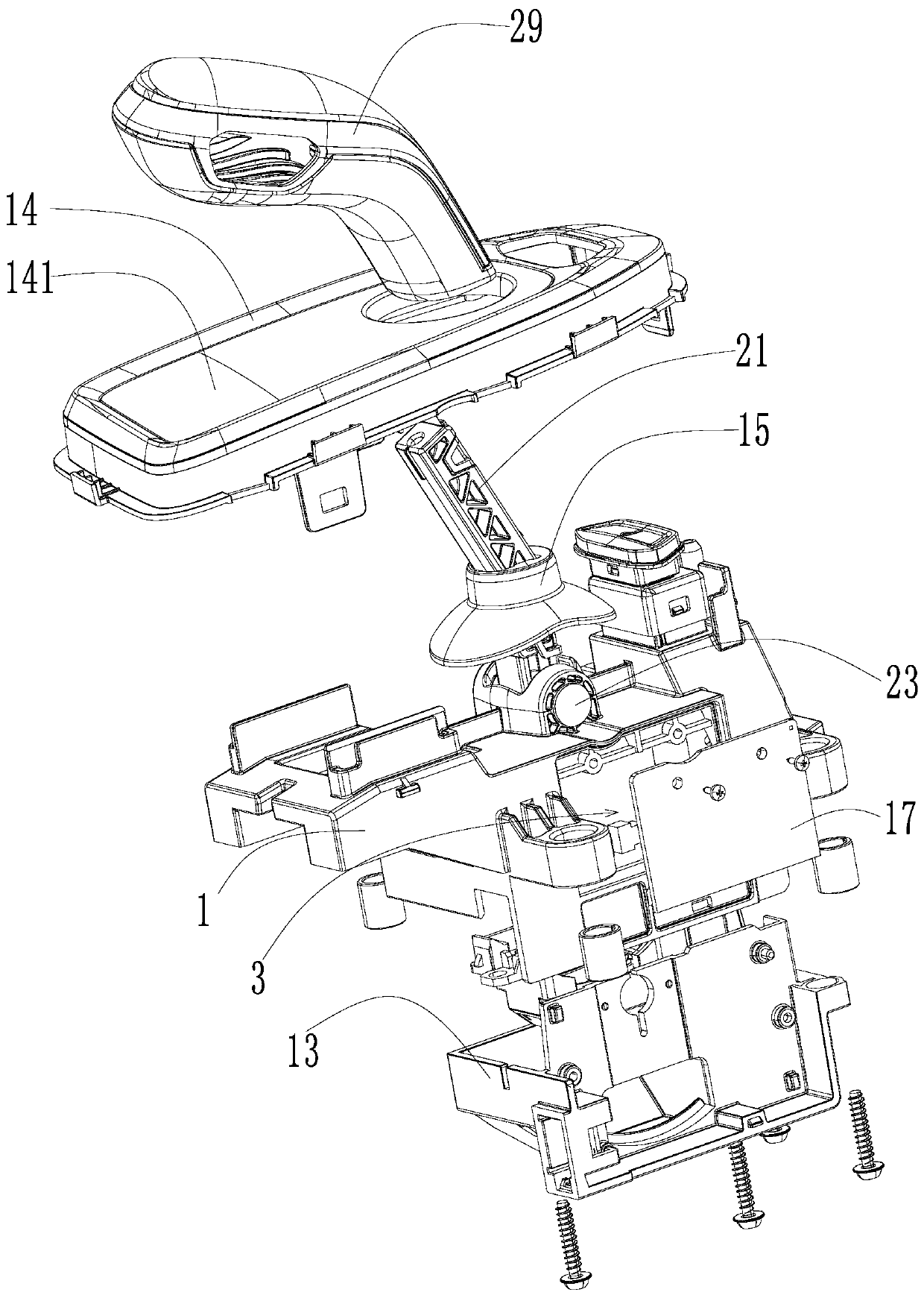

[0057] This embodiment provides an electronic shifter, such as Figure 1 to Figure 2 As shown, the electronic shifter includes: a base, a shifting assembly and a main board;

[0058] The base includes an internal operating cavity, a boss on the upper part, and a bottom cover on the lower part;

[0059] Base 1, base 1 is provided with an operating cavity 11, the upper part of the base 1 protrudes to form a boss 12, and the boss 12 is provided with an opening 121 and an installation cavity 122, and the opening 121 and the installation cavity 122 are both connected to the operation cavity 11 ; A bottom cover 13 is provided below the base 1 .

[0060] The shift assembly includes a shift lever and a rocker arm, the shift lever is hinged on the boss through a pin, and a bush for shock absorption and noise reduction is arranged between the shift lever and the pin; One end of the shift lever passes through the boss and extends into the operating cavity; the rocker arm is arranged on...

Embodiment 2

[0069] This embodiment provides a method for calibrating the gear position of an electronic shifter, such as Figure 3 to Figure 4 As shown, the method includes the steps of:

[0070] Obtain the first release position where the rocker arm of the gear shift assembly reaches the limit position upwards;

[0071] Obtain the second release position where the rocker arm of the gear shift assembly reaches the limit position upwards;

[0072] By means of a preset mean value algorithm, the mean position after adding the first release position and the second release position is obtained; and the obtained mean value is set as the position angle of the intermediate gear.

[0073] Since the electronic shifter mechanism is a monostable state, the release position of the shift lever is the preset middle position, which is set as point Z in this embodiment. Since there is a certain gap at point Z in the actual structure, in order to reduce the error , so the calibration method of point Z fr...

Embodiment 3

[0098] This embodiment provides a system for determining the gear position of an electronic shifter, such as Figure 5 As shown, the system includes:

[0099] Two-way Hall sensor, used to obtain the rotation angle of the rocker arm of the current gear shift assembly;

[0100] The angle comparison module is used to compare the acquired rotation angle of the rocker arm of the current shift assembly with the preset gear position angle, and judge whether the rotation angle of the rocker arm of the current shift assembly is an effective rotation angle;

[0101] The angle confirmation module is used to start timing if the rotation angle of the rocker arm of the current shift assembly is an effective stroke angle, and when the time is the preset effective time, judge whether the rotation angle of the rocker arm of the current shift assembly changes; if it changes, Then the gear position signal is not sent; if it does not change, the gear position is sent as the gear position signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com