A wound dressing composite nanofibrous film and its preparation method

A technology of composite nanofibers and nanofiber membranes, applied in fiber treatment, pharmaceutical formulations, bandages, etc., can solve problems such as wound re-infection, and achieve the effects of low antigenicity, stability, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A wound dressing composite nanofibrous membrane, the preparation raw materials include polyvinylidene fluoride, pH responsive polymer, collagen;

[0031] The preparation method of this composite nanofiber membrane comprises the following steps:

[0032] 1) Preparation of the shell solution: adding the polyvinylidene fluoride: PH-responsive polymer PMMA mass ratio to 1:0.5 into hexafluoroisopropanol, stirring evenly, and preparing the mass volume ratio concentration of 8 % shell solution;

[0033] 2) Preparation of nuclear layer solution: dissolving collagen in hexafluoroisopropanol to prepare a solution with a mass-volume concentration of 10%, then adding drugs and growth factors, and stirring evenly to prepare a nuclear layer solution;

[0034] 3) Inject the shell solution in step 1) and the core layer solution in step 2) into the outer needle and the inner needle of the coaxial electrospinning needle respectively, wherein the inner diameter of the outer needle is 0.8...

Embodiment 2

[0036] The preparation method of this composite nanofiber membrane comprises the following steps:

[0037] 1) Preparation of the shell solution: add the polyvinylidene fluoride: PH responsive polymer PMMA mass ratio to 1:1 in hexafluoroisopropanol, stir evenly, and prepare the mass volume ratio concentration of 12 % shell solution;

[0038] 2) Preparation of nuclear layer solution: dissolving collagen in hexafluoroisopropanol to prepare a solution with a concentration of 12% by mass to volume, then adding drugs, growth factors, and proteins, and stirring evenly to prepare a nuclear layer solution;

[0039] 3) Inject the shell solution in step 1) and the core layer solution in step 2) into the outer needle and the inner needle of the coaxial electrospinning needle respectively, wherein the inner diameter of the outer needle is 1.0 mm, and the inner diameter of the inner needle is 0.4 mm, the electrospinning takes the accepting distance as 15cm, the liquid feeding speed of the ...

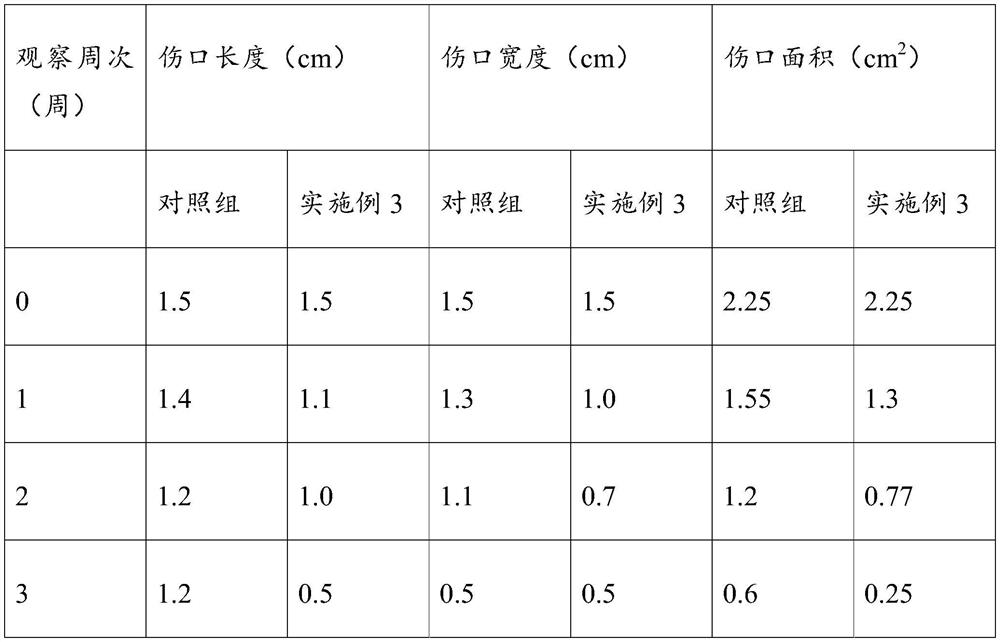

Embodiment 3

[0041] The preparation method of the composite nanofiber membrane of the present embodiment comprises the following steps:

[0042] 1) Preparation of the shell solution: add the polyvinylidene fluoride: PH responsive polymer PMMA mass ratio to 1:2 in hexafluoroisopropanol, stir evenly, and prepare the mass volume ratio concentration of 16 % shell solution;

[0043]2) Preparation of nuclear layer solution: dissolving collagen in hexafluoroisopropanol to prepare a solution with a mass-volume concentration of 15%, then adding drugs, growth factors, and proteins, and stirring evenly to prepare a nuclear layer solution;

[0044] 3) Inject the shell solution in step 1) and the core layer solution in step 2) into the outer needle and the inner needle of the coaxial electrospinning needle respectively, wherein the inner diameter of the outer needle is 0.9 mm, and the inner diameter of the inner needle is 0.5 mm. mm, the electrospinning takes the receiving distance as 18cm, the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com