Experimental method for quickly measuring wheel-track adhesion-creeping curve

An experimental method and technology of measuring wheels, which are applied in measurement devices, railway vehicle testing, instruments, etc., to achieve the effect of reducing experimental time, avoiding errors, and having a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

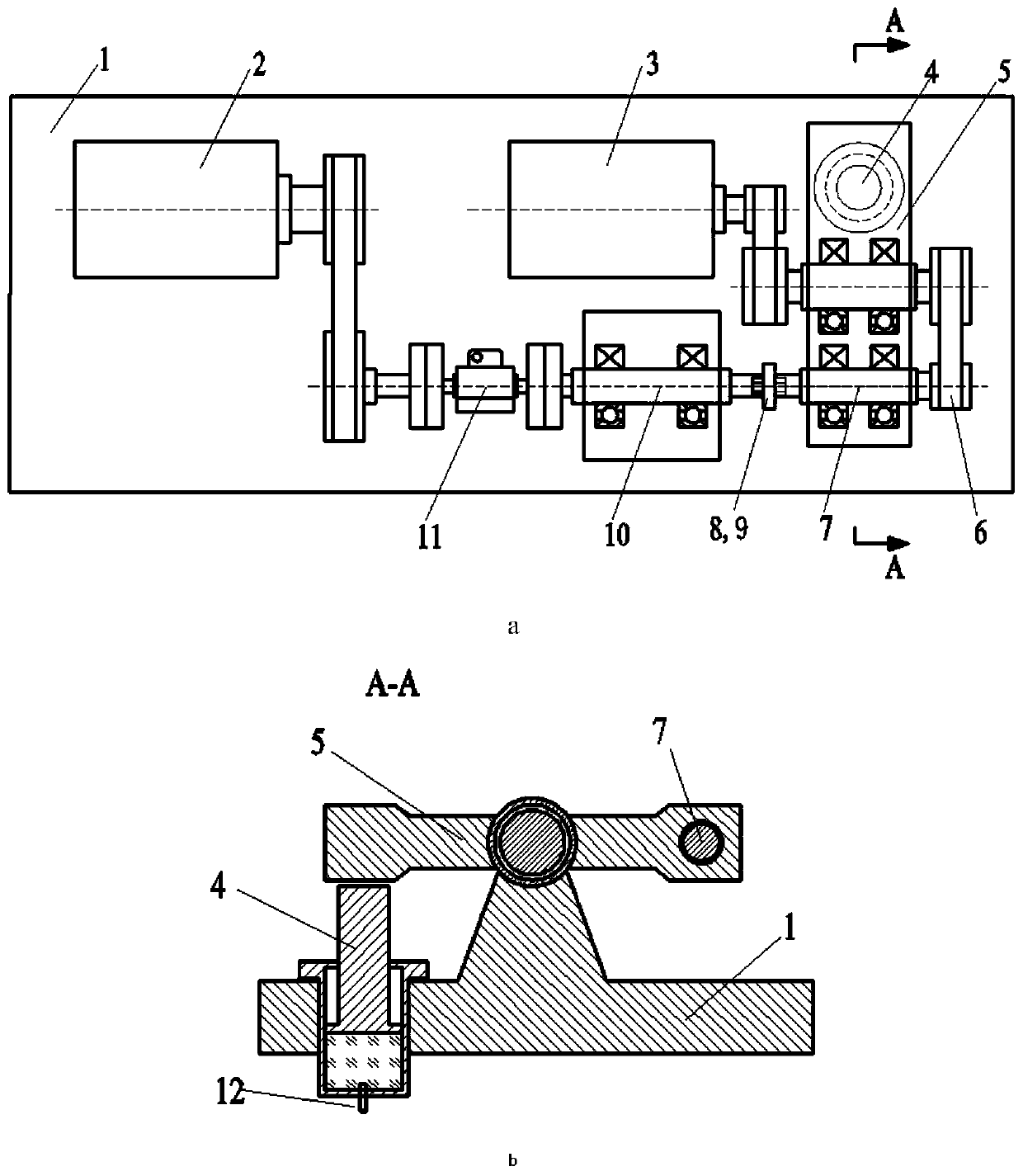

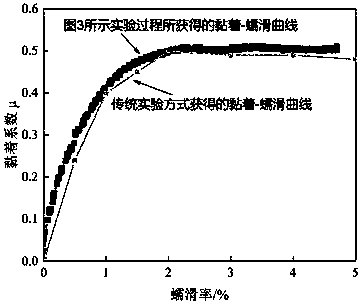

[0037] A kind of embodiment of the inventive method is:

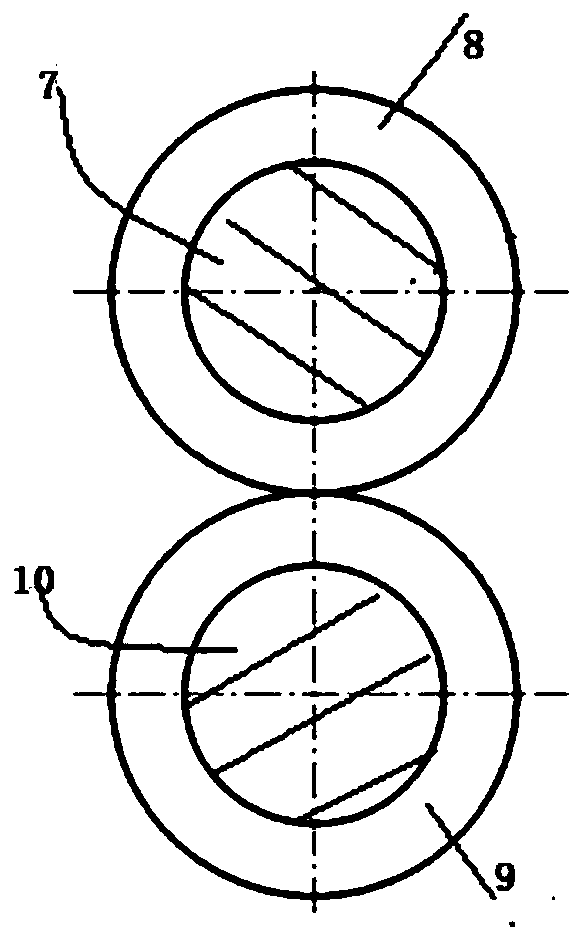

[0038] The wheel and rail samples are processed, the wheel samples are taken from the CL60 wheel tread, and the rail samples are taken from the U71Mn rail head. The two samples were respectively processed into disc samples with an outer diameter of 52 mm, an inner diameter of 32 mm, and a rolling contact surface width of 10 mm. The surface of the sample is polished, and the surface roughness Ra is less than 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com