Speckle preparation method for prefabricated deformed pure titanium and pure titanium detwinning characterization method

A prefabricated deformation, pure titanium technology, applied in surface reaction electrolytic coating, electrolytic coating, coating and other directions, can solve the problem of low calibration rate of EBSD pattern, and achieve the effect of reducing influence and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The speckle preparation method of prefabricated deformed pure titanium of the present invention comprises the following steps:

[0047] (1) Preparation of prefabricated deformed pure titanium with twins;

[0048] The prefabricated deformed pure titanium is obtained by compressively loading the original sample of pure titanium; the engineering strain of the original sample of pure titanium is 0.08-0.1, and the compressive strain rate is 10 -3 the s -1 . The grain size of the original sample pure titanium is 40-60 μm.

[0049] (2) Prepare characteristic speckles on the surface of the prefabricated deformed pure titanium, and then perform EBSD characterization;

[0050] Using an electrolytic cell, prefabricated deformed pure titanium is used as the anode, and the cathode is made of copper, titanium, stainless steel or Ni-Ti alloy, which is composed of perchloric acid and methanol. The volume ratio of perchloric acid to methanol is 1: (8~10), and the voltage The voltage...

Embodiment 1

[0052] The voltage of embodiment 1 is 12V, the voltage of embodiment 2 is 14V, the voltage of embodiment 3 is 15V, the voltage of embodiment 4 is 16V, the voltage of embodiment 5 is 18V, and the voltage of embodiment 6 is 19V. Other parameters of Examples 1 to 6 are as follows: the engineering strain of the original sample pure titanium is 0.09, the grain size of the original sample pure titanium is 50 μm, the cathode is copper, and the volume ratio of perchloric acid to methanol is 1 :9, the current is 0.95~1.05A, the electrolysis time is 3min, and the electrolyte temperature is -32°.

[0053] The characterization results of Examples 1-6 are as follows:

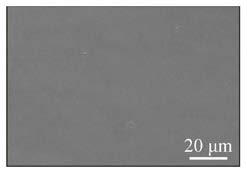

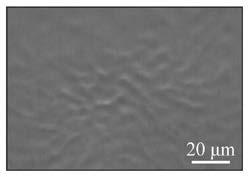

[0054] The SEM photo of the prefabricated deformed pure titanium after the electrolysis of embodiment 1 is as follows figure 1 shown, from figure 1 It can be seen that the surface of the prefabricated deformed pure titanium after electrolysis is very smooth, and the image gray values in different regions are almost the s...

Embodiment 7

[0055] The current of Example 7 is 0.75-0.85A, the current of Example 8 is 0.85-0.95A, and the current of Example 9 is 1.05-1.15A. Other parameters of Examples 7 to 9 are as follows: the engineering strain of the original sample pure titanium is 0.09, the grain size of the original sample pure titanium is 50 μm, the cathode is copper, and the volume ratio of perchloric acid to methanol is 1 :9, the voltage is 16V, the electrolysis time is 3min, and the electrolyte temperature is -32°.

[0056] The characterization result of embodiment 7~9 is as follows:

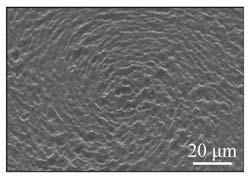

[0057] Figure 7-9 These are the SEM photos of the prefabricated deformed pure titanium in Examples 7-9, respectively. From Figure 7 It can be seen that the surface of the prefabricated deformed pure titanium after electrolysis is smooth and has no characteristic speckles. Compared image 3 , Figure 7-9 It can be seen that with the increase of current, the surface of the prefabricated deformed pure titanium after elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com