Dirt detection method

A detection method and stain technology, applied in the field of visual inspection, can solve the problems of easy false detection, difficult parameter adjustment, low detection efficiency, etc., and achieve the effect of improving accuracy and reliability, improving detection efficiency, and avoiding object structure interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

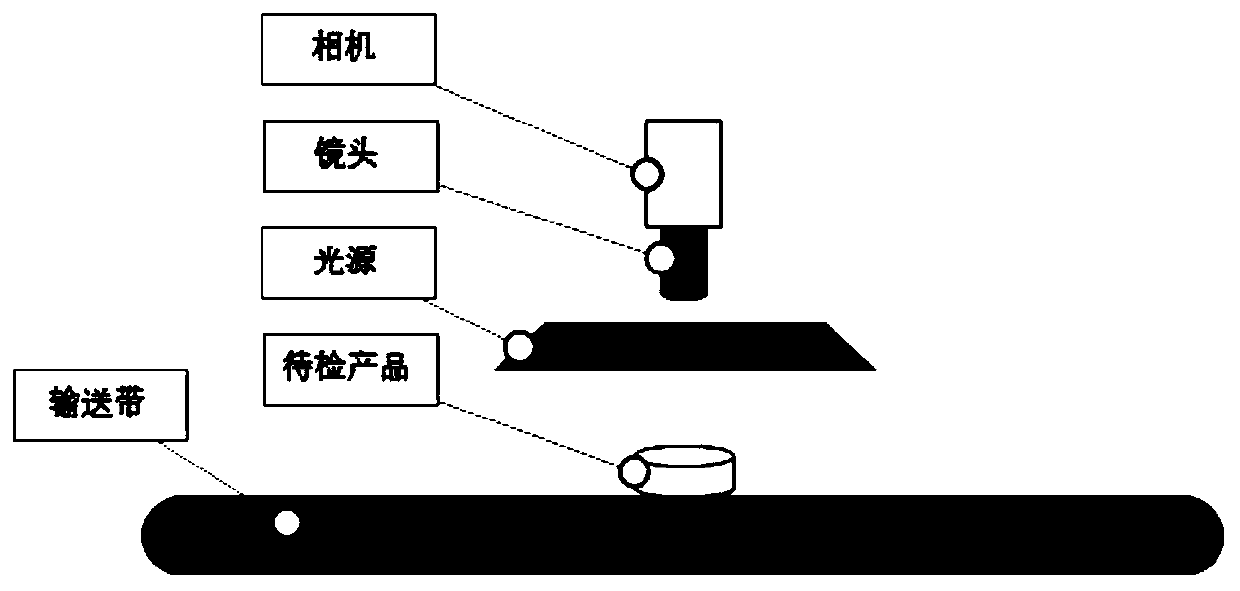

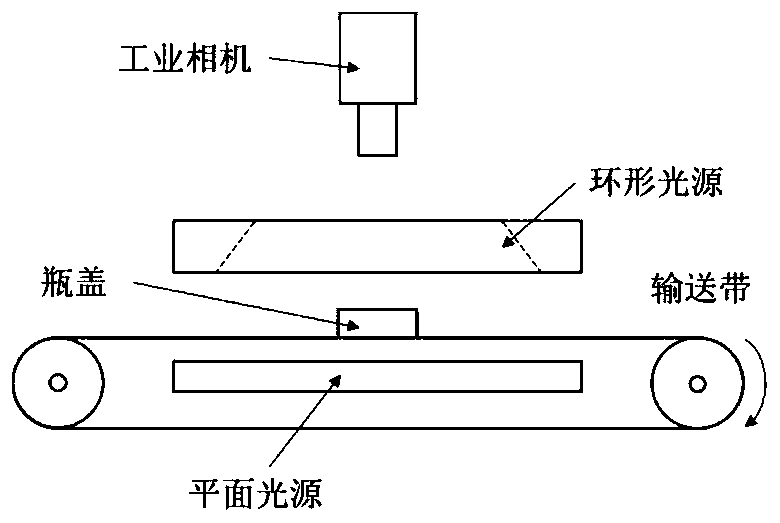

[0055] This embodiment provides a stain detection method, the method adopts such as figure 2 The detection device shown in the figure includes an industrial camera, a ring light source, an object to be tested and a plane light source; the detection device uses a set of front ring light sources to ensure the detection effect of the inner surface defects of the cover, and also adds a set of back plane light sources, Guarantee the detection effect of impurities and color difference inside the material in the cover. In this example, the object to be tested is a lid, which can be a bottle cap or a bucket lid; in other embodiments, we can also detect tableware such as plastic / paper bowls, plastic / paper cups, and plastic / paper plates.

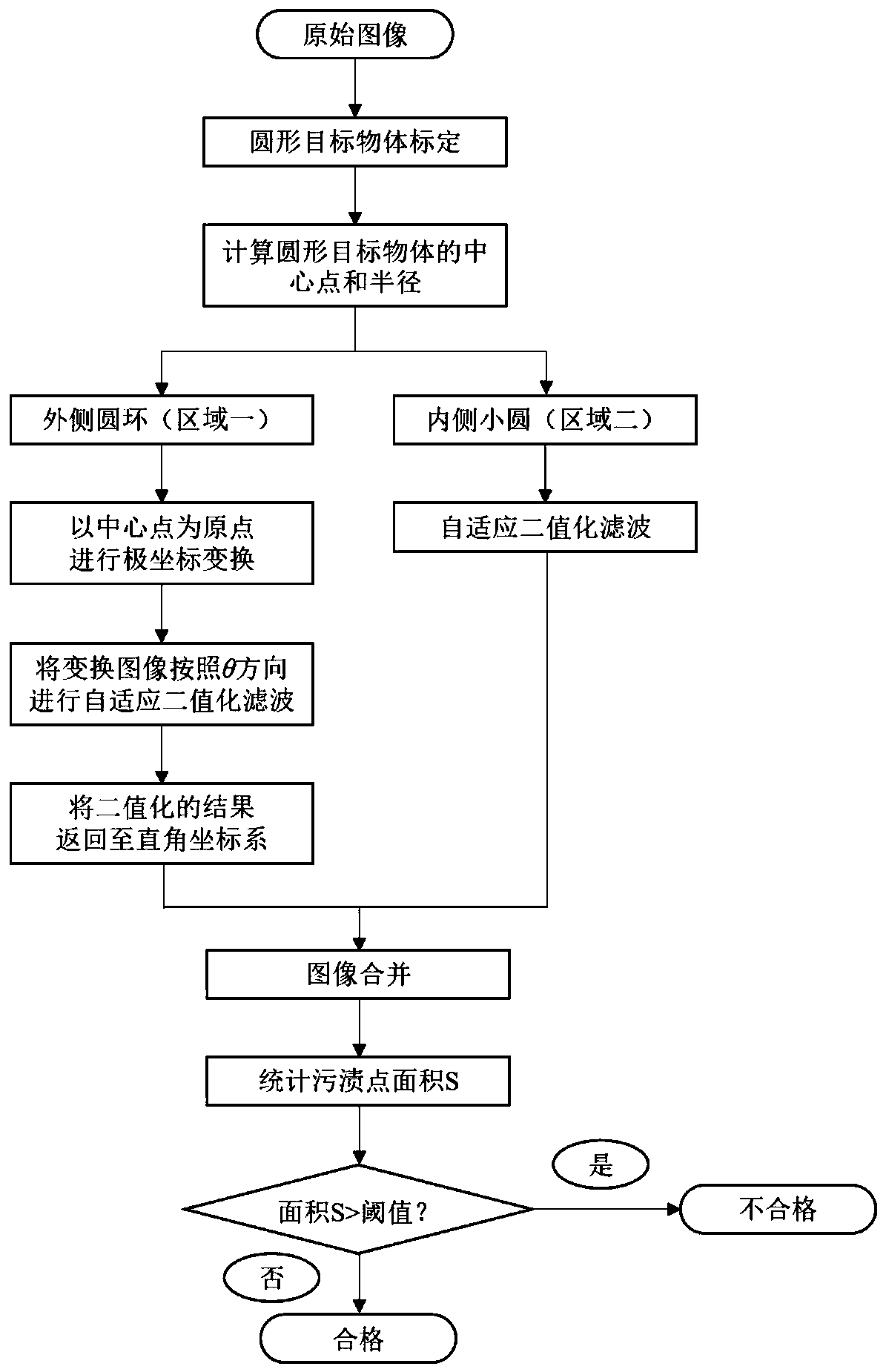

[0056] Such as image 3 As shown, the implementation process of the detection method is as follows:

[0057] Step 1. Using the above detection device to obtain the grayscale image src of the object to be tested 0 (x,y), such as Figure 4 shown. ...

Embodiment 2

[0110] This embodiment 2 respectively uses the existing image segmentation method and the image segmentation method described in listing embodiment 1 to carry out image segmentation on a certain product, and obtains the comparison diagram of the segmentation effect of the two, as Figure 10 As shown, among them, Figure 10 (Left) Image using existing image segmentation (divided into 4 regions), Figure 10 The (right) figure adopts the image segmentation method described in Example 1 (divided into two regions).

[0111] In this embodiment 2, a certain product is detected by using the existing detection method and the detection method described in the above-mentioned embodiment 1 respectively, and the detection results are obtained, and the detection results are compared, as Figure 11 As shown, among them, Figure 11 (Left) Figure using existing detection methods, Figure 11 The (right) figure adopts the detection method described in Example 1. As can be seen from the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com