Samarium cobalt magnet and method for producing same

A manufacturing method, the technology of samarium-cobalt magnets, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve the problems of increasing production costs, and achieve low production costs, large residual magnetism, and high coercive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

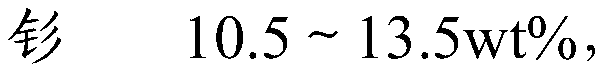

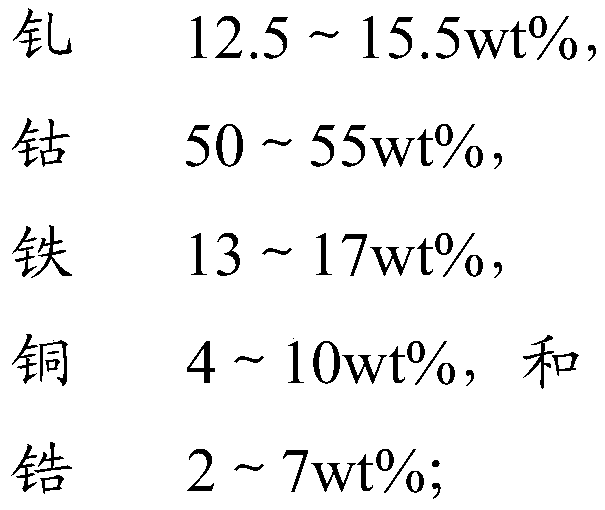

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~2

[0072] Smelting: According to the formula in Table 1, the raw materials of samarium, gadolinium, cobalt, iron, copper and zirconium are smelted in a high-vacuum and high-frequency induction furnace. After the smelting is completed, the temperature is kept at 1460 ° C for 5 minutes, and then poured into the mold and cooled to obtain samarium. Cobalt alloy.

[0073] Pulverizing: The samarium cobalt alloy is mechanically crushed into coarse powder below 10mm (for example, 500μm) in a jaw crusher, and then subjected to high-pressure jet mill to obtain an alloy powder with an average particle size of 3.5μm.

[0074] Mixing: According to the formula in Table 1, the alloy powder was mixed with zirconium powder with an average particle size of 5 μm for 200 min to obtain a mixture.

[0075] Magnetic field forming and isostatic pressing: the mixture is oriented and formed in a magnetic field press, the magnetic field strength is 2T, the pressure is 5MPa, and the density is 4g / cm 3 's b...

Embodiment 1A~B and comparative example 1A~B

[0082] The addition amount of zirconium powder in the mixing step was changed, and the remaining conditions were the same as those in Example 1 to obtain a samarium cobalt magnet. The amount of samarium and gadolinium and the amount of zirconium powder added are shown in Table 2.

[0083] Table 2

[0084]

[0085] See Table 2 for the variation of remanence with temperature. It can be seen from the table that by controlling the amount of zirconium powder at 0.1-0.35wt%, the samarium cobalt magnet has a positive remanence temperature coefficient, and the remanence at high temperature is relatively large.

[0086] table 3

[0087]

[0088] See Table 3 for the variation of coercivity with temperature. It can be seen from the table that the samarium cobalt magnet has higher coercivity by controlling the amount of zirconium powder at 0.1-0.35wt%.

Embodiment 2A~B and comparative example 2A~B

[0090] The addition amount of zirconium powder in the mixing step was changed, and the remaining conditions were the same as those in Example 2 to obtain a samarium cobalt magnet. The amount of samarium and gadolinium and the amount of zirconium powder added are shown in Table 4.

[0091] Table 4

[0092]

[0093] See Table 4 for the variation of remanence with temperature. It can be seen from the table that by controlling the amount of zirconium powder at 0.1-0.35wt%, the samarium cobalt magnet has a positive remanence temperature coefficient, and the remanence at high temperature is relatively large.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com