Method for preparing metallic element doped La2Mo2O9 solid electrolyte

A solid electrolyte, la2mo2o9 technology, applied in circuits, fuel cells, electrical components, etc., can solve problems such as phase transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (La 1-x Pb x ) 2 Mo 2 o 9-δ The preparation method of solid electrolyte, the steps are as follows:

[0035] ① There are 4 groups in the experiment, and x is taken from 0, 0.2, 0.4, 0.6 respectively. According to the target sample (La 1-x Pb x ) 2 Mo 2 o 9-δ The stoichiometric ratio of La(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 O, Pb(NO 3 ) 2 In a beaker, add an appropriate amount of distilled water and stir to dissolve.

[0036] ②, then add citric acid to the beaker (the molar amount of citric acid is 1.5 times the amount of metal ions contained in the components), and adjust the pH value to neutral with ammonia water, transfer to CS-BA type digital display ultrasonic water bath for oscillation Ultrasonic in the container for 1h, after uniform dispersion, put into WBFY201 microwave chemical reactor at 80°C for 2h microwave reaction, and evaporate to obtain wet gel.

[0037] ③. Put the obtained wet gel sample into a drying oven and dry it at 120°C...

Embodiment 2

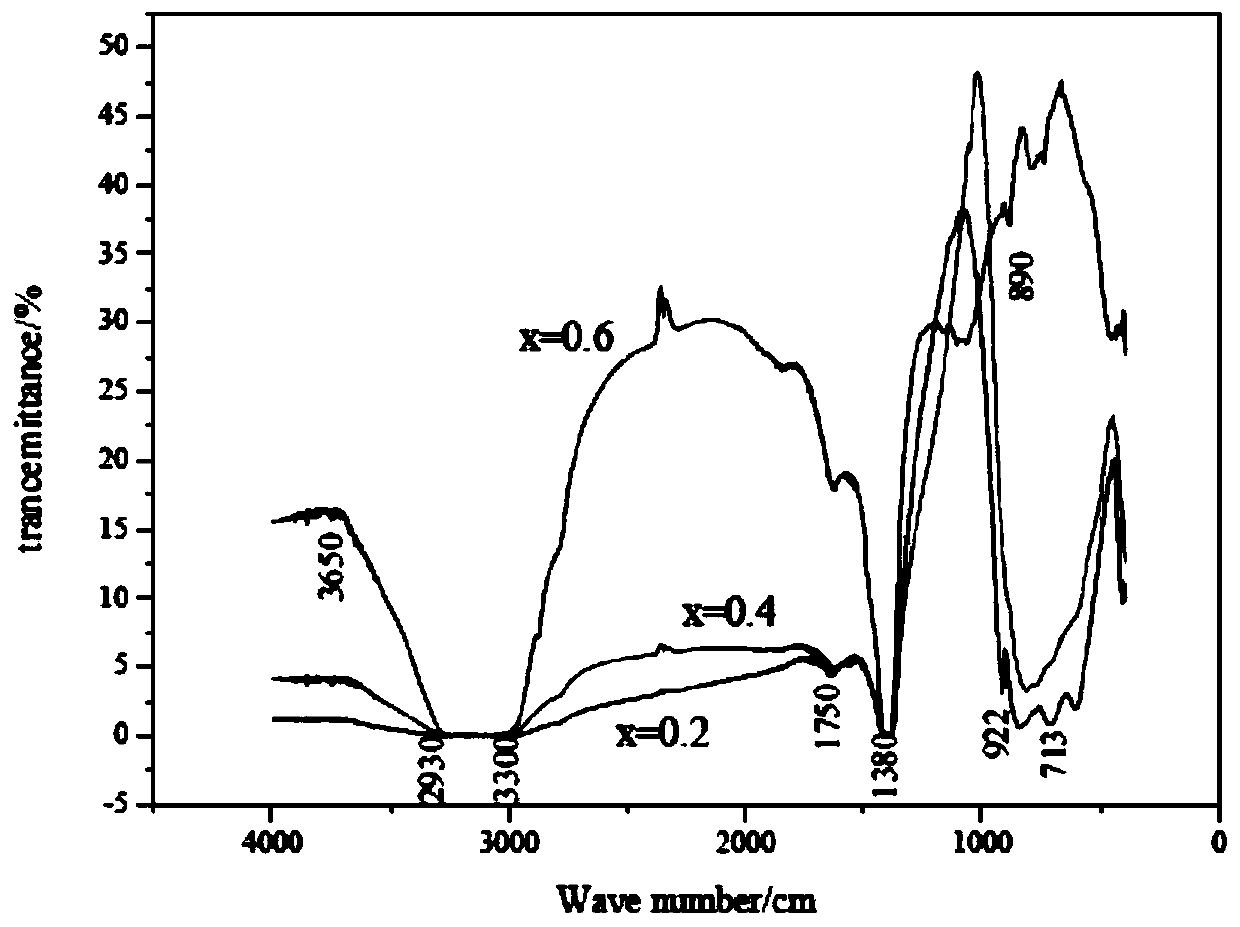

[0041] (La 1-x Pb x ) 2 Mo 2 o 9-δ Performance Characterization of Solid Electrolyte

[0042] 1. Characterization method

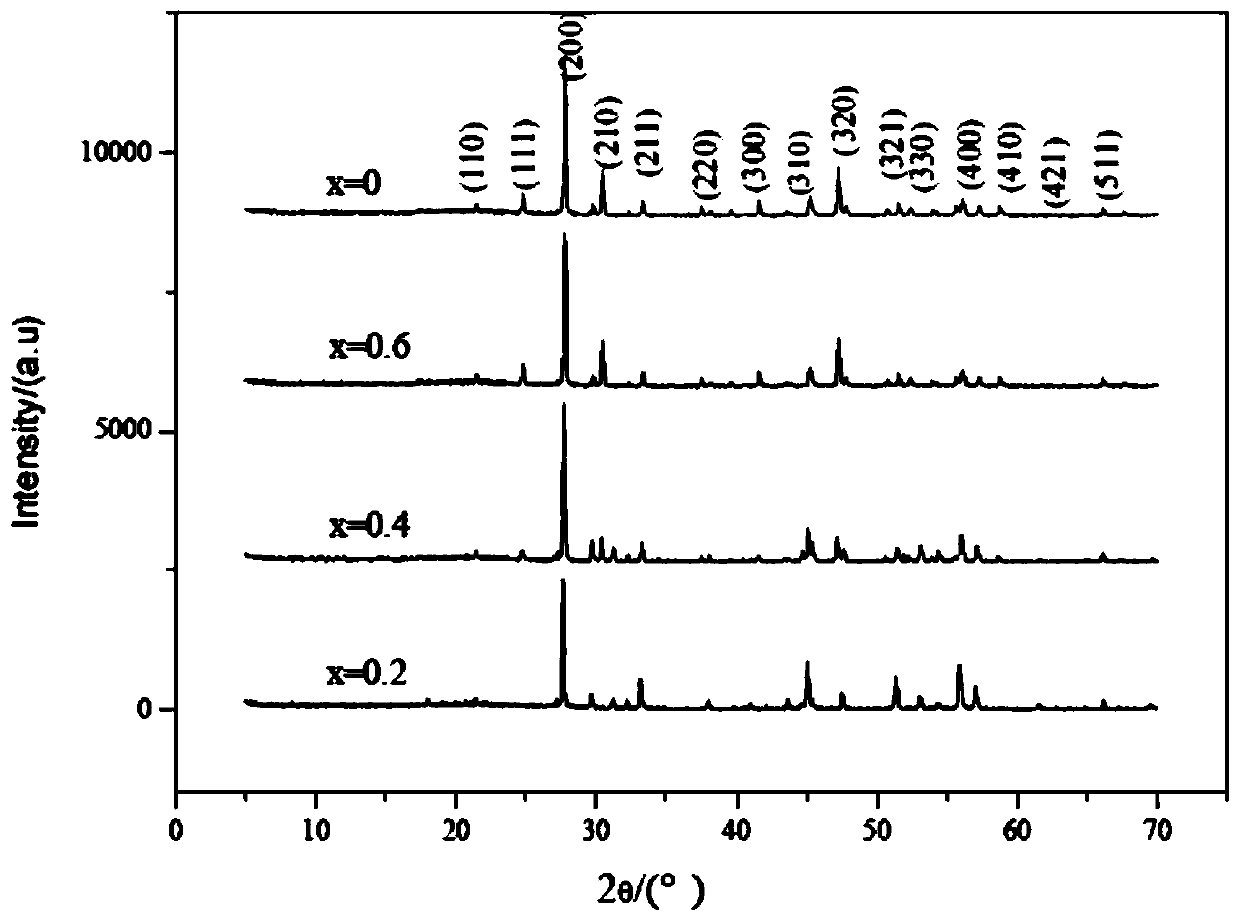

[0043] 1.1. Principle of XRD test method

[0044] XRD pattern analysis is a very common material analysis method. It uses the diffraction of X-rays received by the sample to produce different absorption peaks. a research tool. The powder obtained after calcination at different temperatures was tested by X-ray diffraction (XRD). The test parameters used in this experiment were the wavelength (λ) of 0.1542nm, the scan rate (V) of 35 / min, and the scan range (2θ) of 5 °~80°. XRD analysis is based on the characteristic that X-rays have specific energies for different elements. After drawing them into spectra with oring software, the corresponding elements can be found according to the magnitude of different energies.

[0045] 1.2. Principle of SEM-EDS test method

[0046] The SEM-EDS combination is the most widely used microscopic analysis instrument ...

Embodiment 3

[0092] (La 1-x Ti x ) 2 Mo 2 o 9-δ The preparation method of solid electrolyte, the steps are as follows:

[0093] ① There are 3 groups in the experiment, and x is taken from 0.2, 0.3, and 0.4 respectively. According to the target sample (La 1-x Ti x ) 2 Mo 2 o 9-δ The stoichiometric ratio of La(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 O. Put tetrabutyl titanate in a beaker, add appropriate amount of distilled water and fully stir to dissolve.

[0094] ②, then add citric acid to the beaker (the molar amount of citric acid is 1.5 times the amount of metal ions contained in the components), and adjust the pH value to neutral with ammonia water, transfer to CS-BA type digital display ultrasonic water bath for oscillation Ultrasonic in the container for 1h, after uniform dispersion, put into WBFY201 microwave chemical reactor at 80°C for 2h microwave reaction, and evaporate to obtain wet gel.

[0095] ③. Put the obtained wet gel sample into a drying oven and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com