Rotor liquid cooling system structure suitable for inner rotor motor

An internal rotor motor and system structure technology, applied in the field of motor cooling system and rotor liquid cooling system structure, can solve the problems of motor heating, temperature rise, damage insulation, narrow application range, etc., to improve power density, increase electromagnetic load, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in conjunction with the accompanying drawings.

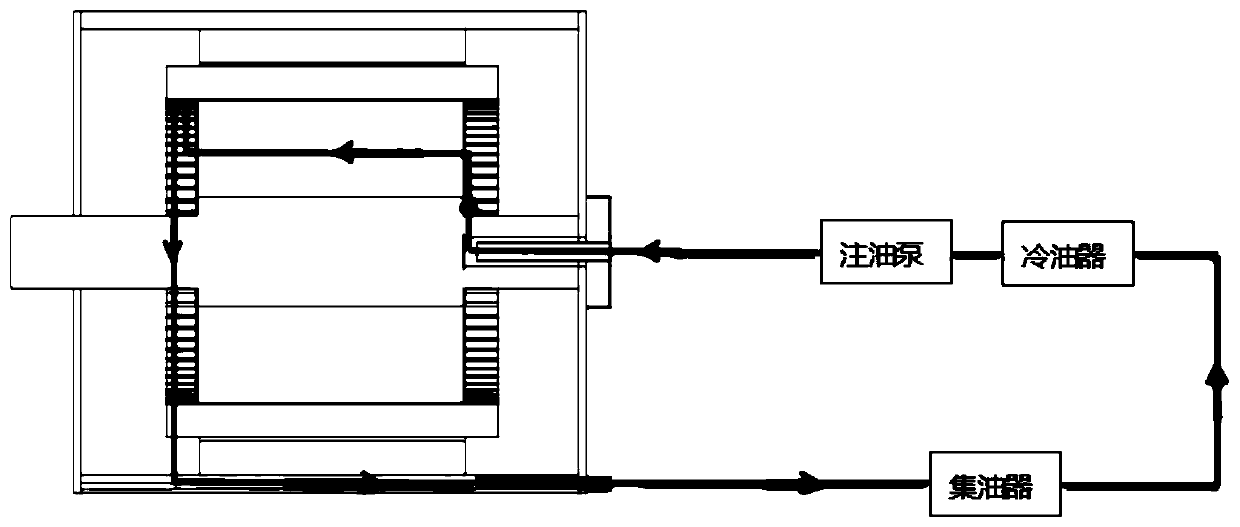

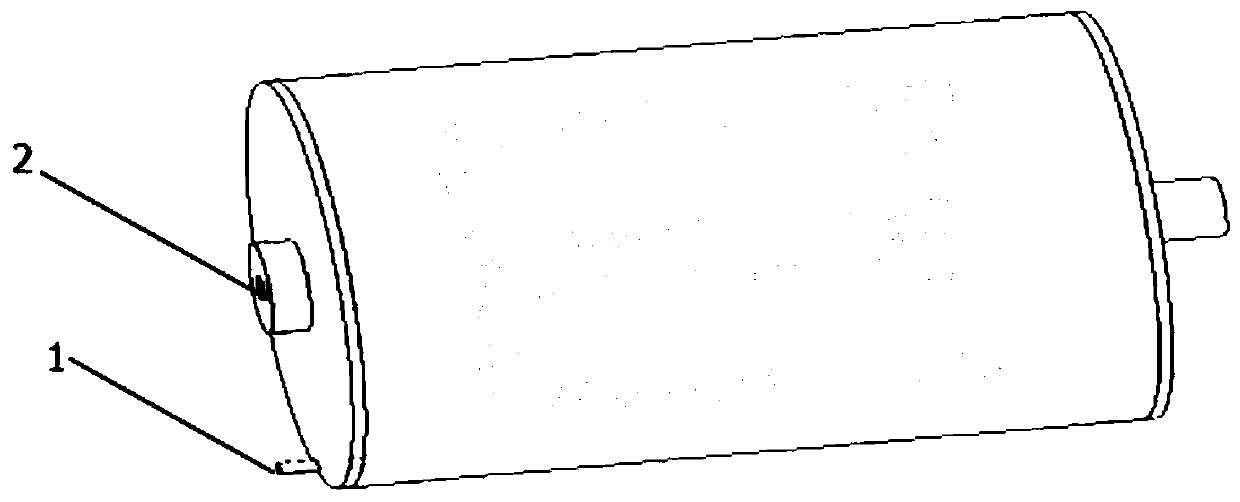

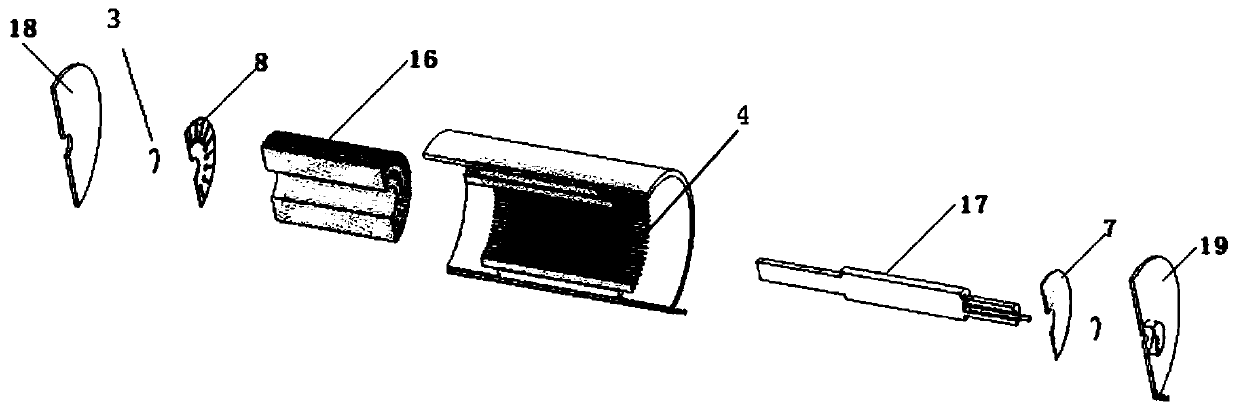

[0033] A rotor liquid cooling system structure suitable for an inner rotor motor in this embodiment includes an external circulation part and an inner cooling part. The inner rotor motor includes a rear end cover, an inner rotor 16 and a rotating shaft 17 inserted into the inner rotor, The rear end cover is provided with a rear end cover liquid inlet 2 and a rear end cover liquid outlet 1, and the two ends of the rotating shaft 17 extend outward to the outside of the inner rotor 16, one side of the rotating shaft 17 is the liquid inlet, and the other The side is the liquid outlet, and at least one liquid inlet channel 5 is opened on the rotating shaft 17 of the liquid inlet end, and a number of radial guide channels 10 are opened on the rotating shaft 17 inside the inner rotor 16, and a number of axial liquid passages are opened on the inner rotor 16. The hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com