Method and system for suppressing torque ripple of brushless DC motor

A technology of brush DC motor and torque ripple, which is applied in the direction of torque ripple control, etc., can solve the problems of high cost, low control efficiency, and inconspicuous torque ripple suppression, and achieve better suppression of torque ripple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

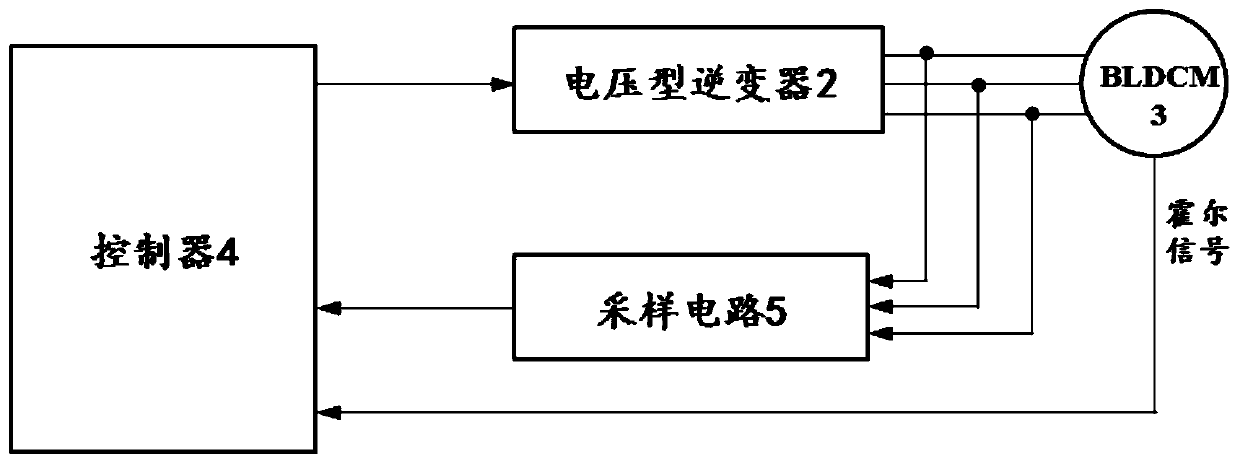

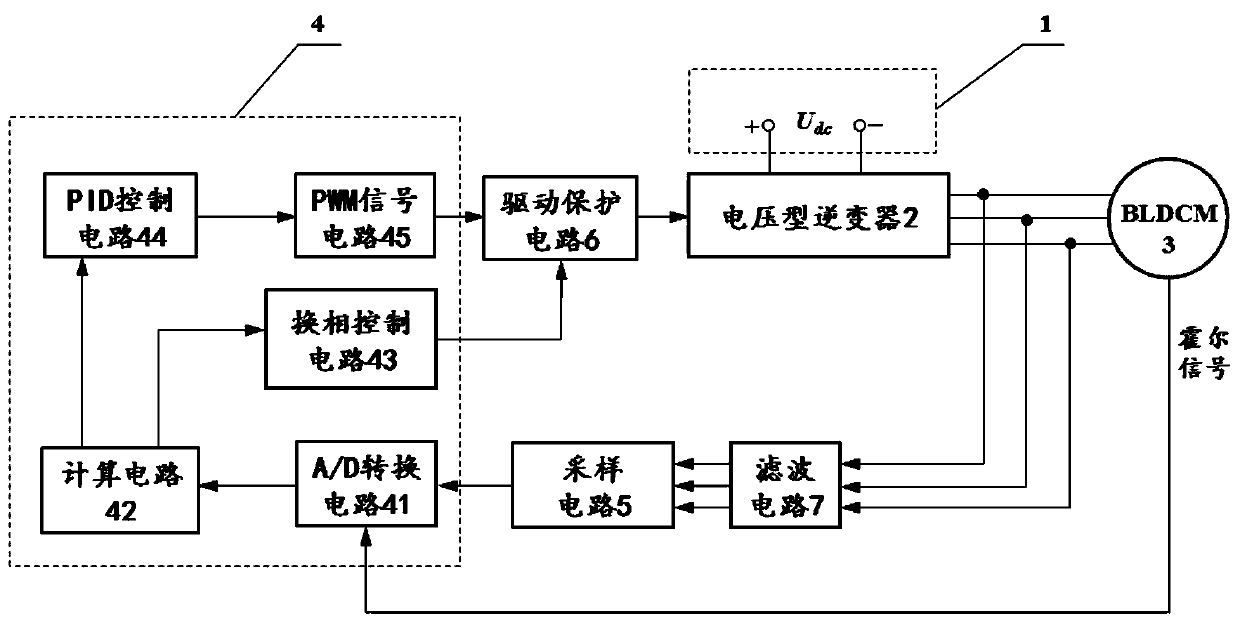

[0070] Embodiment one, as figure 1 As shown, a brushless DC motor torque ripple suppression system includes a voltage source inverter 2, a controller 4 and a sampling circuit 5;

[0071] The voltage-type inverter 2 is used to control the opening and closing of each phase of the brushless DC motor 3;

[0072] The sampling circuit 5 is used to collect the three-phase phase current during the operation of the brushless DC motor 3, and send the collected three-phase phase current to the controller 4;

[0073] The controller 4 is used to receive the three-phase phase current and the Hall signal collected by the Hall sensor of the brushless DC motor 3; Whether the brushless DC motor 3 is in the commutation state, when the judgment result is no, adopt the two-two conduction control mode to control the voltage type inverter, and when the judgment result is yes, use the two-two conduction and three-three The conduction switching control mode controls the voltage source inverter.

[...

Embodiment 2

[0140] Embodiment two, such as Figure 7 Shown, a kind of suppression method of brushless DC motor torque ripple, it adopts the suppression system of brushless DC motor torque ripple of the present invention, comprises the following steps:

[0141] S1: Obtain the Hall signal collected by the Hall sensor in the brushless DC motor and the three-phase phase current during the operation of the brushless DC motor, and according to the Hall signal and the The three-phase phase current determines whether the brushless DC motor is in the commutation state, if not, enters S2, and if so, enters S3;

[0142] S2: controlling the voltage source inverter by using the pairwise conduction control method;

[0143] S3: Controlling the voltage source inverter by using the two-two conduction and three-three conduction switching control mode.

[0144] In the commutation stage, the two-two conduction control method is adopted first. Since the current of the inductance cannot change suddenly in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com