Induction heating coil applied to hot-charging knife handle

A technology of induction heating coils and coils, applied in induction heating, induction heating control, induction heating devices, etc., can solve the problems of high price and achieve the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

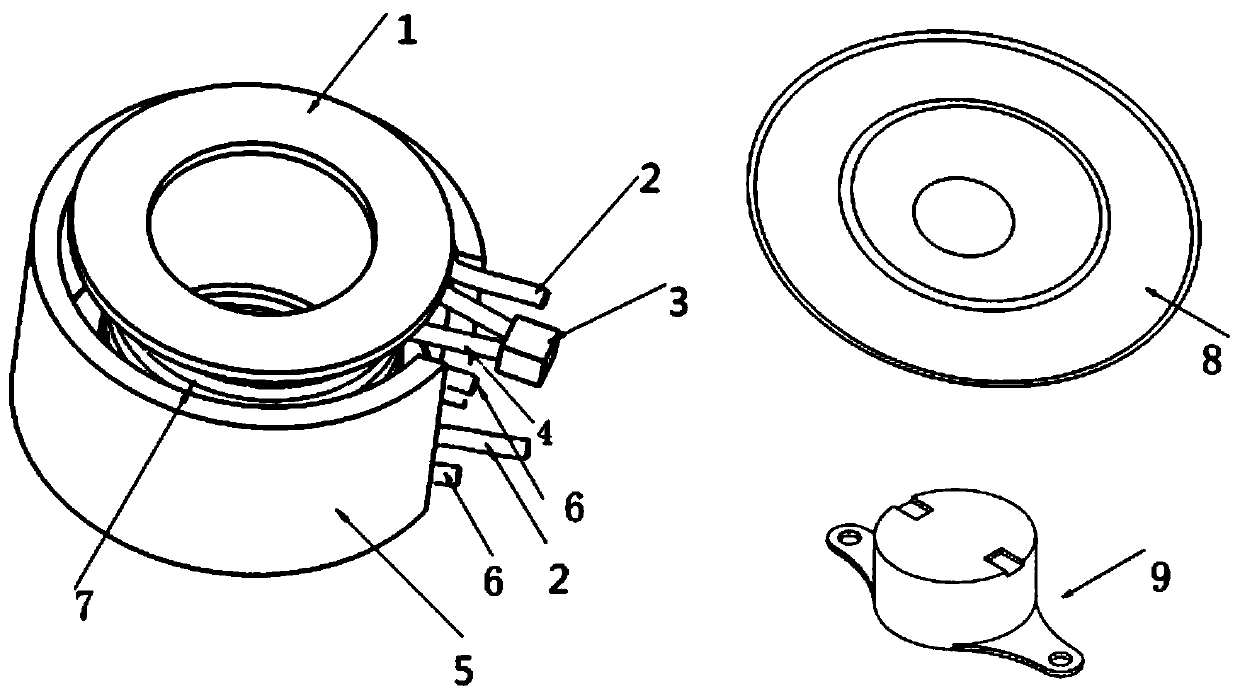

[0033] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] like figure 1As shown, the present invention is applied to the induction heating coil of the hot-fit tool handle, including the winding column 1, the coil 2, the working indicator light 3, the ordinary wire 4, the bimetal thermostat 9 and the lead wire 6 of the temperature control circuit, the magnetic field Gathering tank 5, magnetic field gathering cover 8, silicone potting glue 7 is added in the gap between coil 2 and magnetic field gathering tank 5, magnetic field gathering cover 8 is placed on the top of winding post 1, bimetallic thermostat 9 passes through silicone The potting glue adheres to the surface of the coil 2, and the coil 2 adopts multiple strands of polyurethane round copper strands.

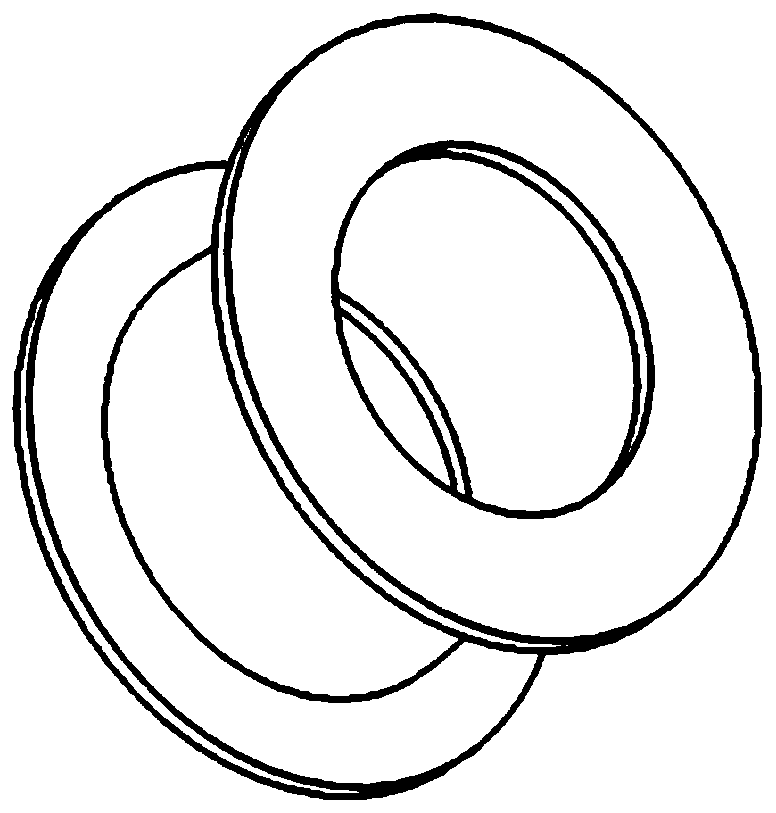

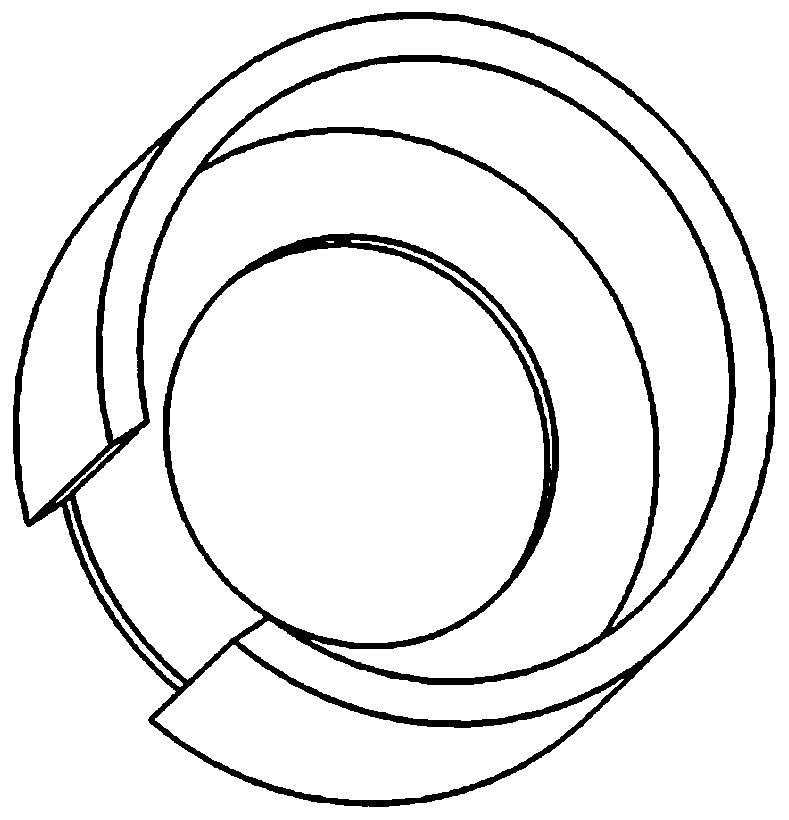

[0035] like figure 2 As shown, the winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com