Container and biogas installation

A biogas and container technology, applied in the field of containers, can solve the problems of equipment consumption, high investment costs and high operating costs, and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

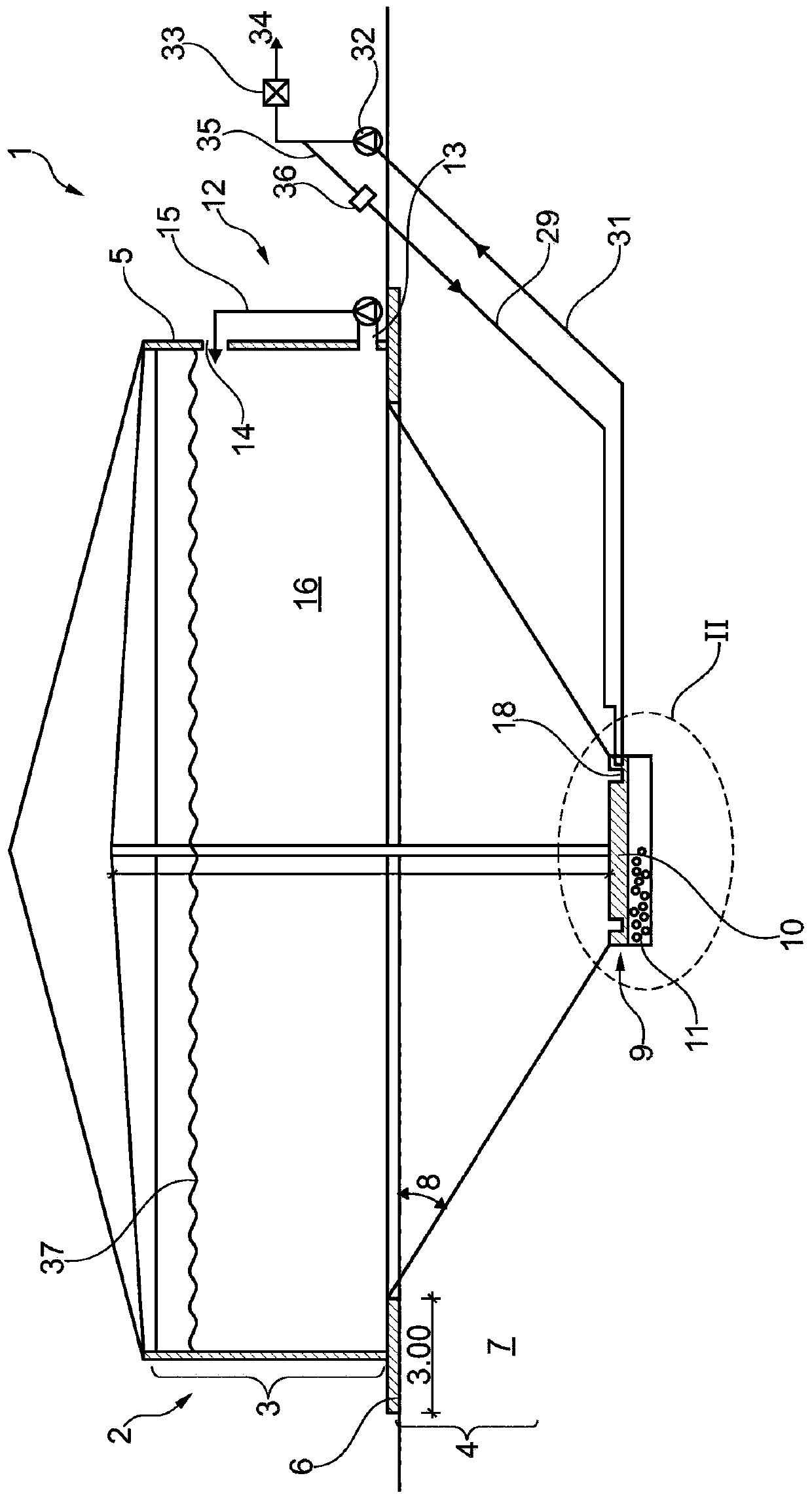

[0030] figure 1 A preferred embodiment of a biogas plant 1 according to the invention is shown in longitudinal section, which has an embodiment of the container 2 according to the invention. like infigure 1 As can be seen in , the container 2 has a cylindrical main section 3 to which a conical tapering section 4 is attached downwards. The cylindrical main section 3 has a wall 5 made of reinforced concrete. The wall 5 rests on an annular base 6 .

[0031] The conical tapering section 4 is located in the soil 7 in a lagoon-like manner. The tapering section 4 is made of PE-HD. The walls of the tapering section 4 form an angle 8 of 10°-45°, preferably 30°, with respect to the horizontal.

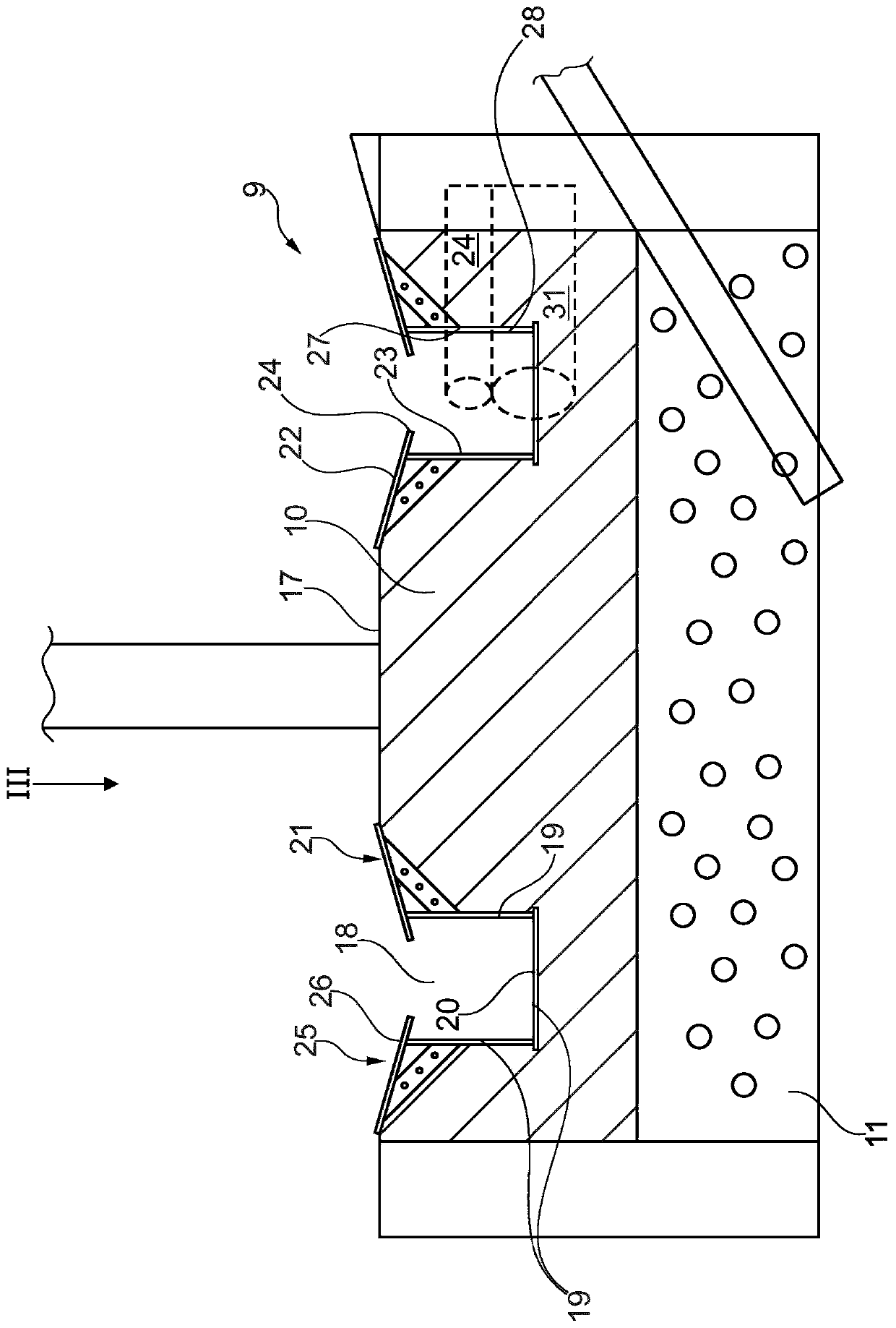

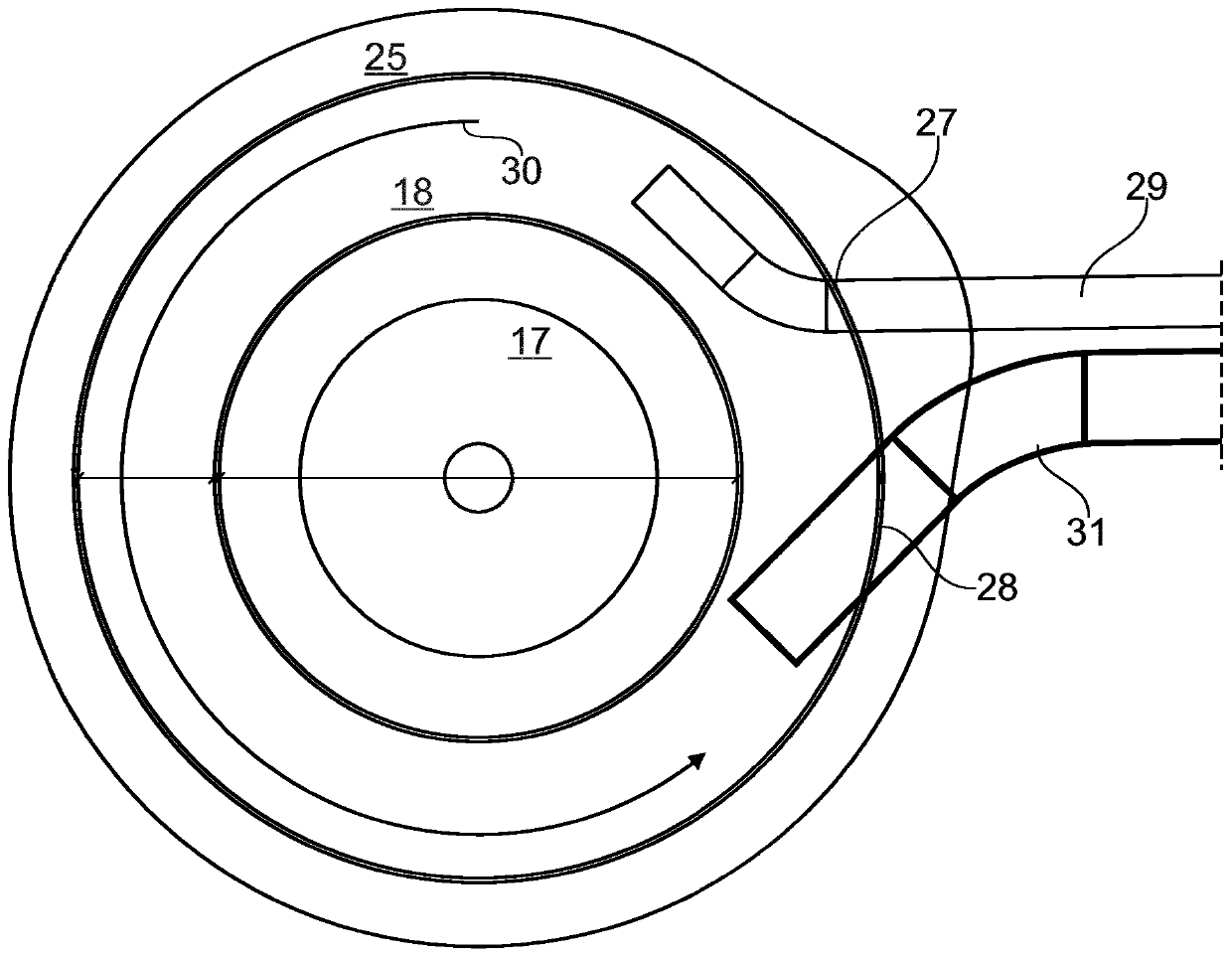

[0032] The tapering section 4 ends downwardly with a bottom section 9 . The bottom section 9 is substantially made of a floor 10 made of reinforced concrete. The floor 10 is installed on a gravel bed 11 in the soil 7 in the region of the floor 10 in order to possibly pump out groundwater. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com