Lutein-enriched candy and preparation method thereof

A technology of lutein and candy, which is applied in the fields of confectionery, confectionary industry, food science, etc., and can solve the problems of development and utilization without in-depth research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

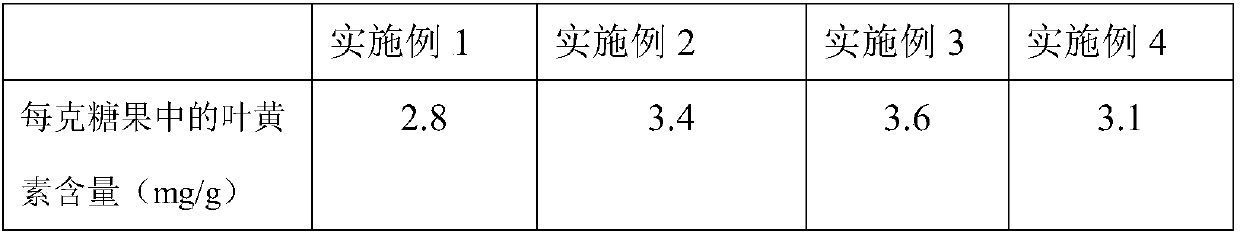

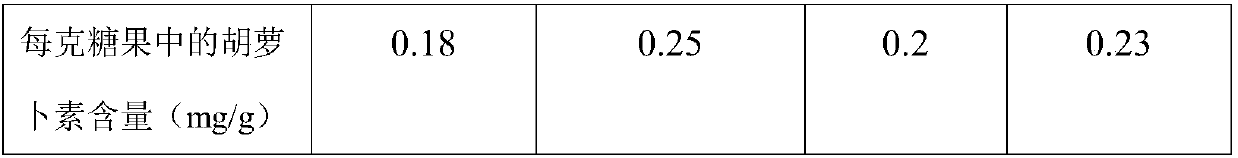

Examples

Embodiment 1

[0029] Preparation of Pumpkin Extract Sugar Sauce

[0030] (1) Dissolve the pumpkin powder in an aqueous ethanol solution with a volume concentration of 60%, the density of the pumpkin powder in the aqueous ethanol solution is 0.07g / mL, extract for 35 hours, and then centrifuge at 4000-5000r / min to obtain a supernatant , concentrating the supernatant under reduced pressure at 45°C to a soluble solid content of 20%, to obtain pumpkin extract;

[0031] (2) Dissolve 15 parts of sucrose in water, then add 10 parts of starch syrup, heat to 105°C, add 0.005 part of orange peel, boil the sugar in a vacuum at 140°C to reduce the water content to 94%; then add 13 parts of pumpkin extract, Stir well to get pumpkin extract sugar sauce.

[0032] Preparation of corn extract

[0033] Add an aqueous ethanol solution with a volume concentration of 75% to the corn kernels, the density of the corn kernels in the aqueous ethanol solution is 0.1g / mL, add sodium lauryl sulfate accounting for 1.2...

Embodiment 2

[0044] Preparation of Pumpkin Extract Sugar Sauce

[0045] (1) Dissolve the pumpkin powder in an aqueous ethanol solution with a volume concentration of 80%, the density of the pumpkin powder in the aqueous ethanol solution is 0.05g / mL, extract for 30h, and then centrifuge at 4000-5000r / min to obtain a supernatant , concentrating the supernatant under reduced pressure at 55°C to a soluble solid content of 30%, to obtain pumpkin extract;

[0046] (2) Dissolve 12 parts of sucrose in water, then add 12 parts of starch syrup, heat to 107°C, add 0.003 part of orange peel, boil the sugar in a vacuum at 130°C to reduce the water content to 97%; then add 15 parts of pumpkin extract, Stir well to get pumpkin extract sugar sauce.

[0047] Preparation of corn extract

[0048] Add an aqueous ethanol solution with a volume concentration of 85% to the corn kernels, the density of the corn kernels in the aqueous ethanol solution is 0.08g / mL, add sodium lauryl sulfate accounting for 1% of t...

Embodiment 3

[0059] Preparation of Pumpkin Extract Sugar Sauce

[0060] (1) Dissolve the pumpkin powder in an aqueous ethanol solution with a volume concentration of 70%, the density of the pumpkin powder in the aqueous ethanol solution is 0.06g / mL, extract for 40h, and then centrifuge at 4000-5000r / min to obtain a supernatant , concentrating the supernatant under reduced pressure at 50°C to a soluble solid content of 15%, to obtain pumpkin extract;

[0061] (2) Dissolve 18 parts of sucrose in water, then add 8 parts of starch syrup, heat to 106°C, add 0.01 part of orange peel, boil the sugar in a vacuum at 135°C to reduce the water content to 95%; then add 10 parts of pumpkin extract, Stir well to get pumpkin extract sugar sauce.

[0062] Preparation of corn extract

[0063] Add an aqueous ethanol solution with a volume concentration of 95% to the corn kernels, the density of the corn kernels in the aqueous ethanol solution is 0.06g / mL, add sodium lauryl sulfate accounting for 0.8% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com