Prosthetic socket having deformation adjusting and controlling function and 4D printing forming method of prosthetic socket

A technology of receiving cavity and prosthesis, applied in the field of medical rehabilitation equipment, can solve the problems of inability to dynamically adjust, waste of manpower and material resources, environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

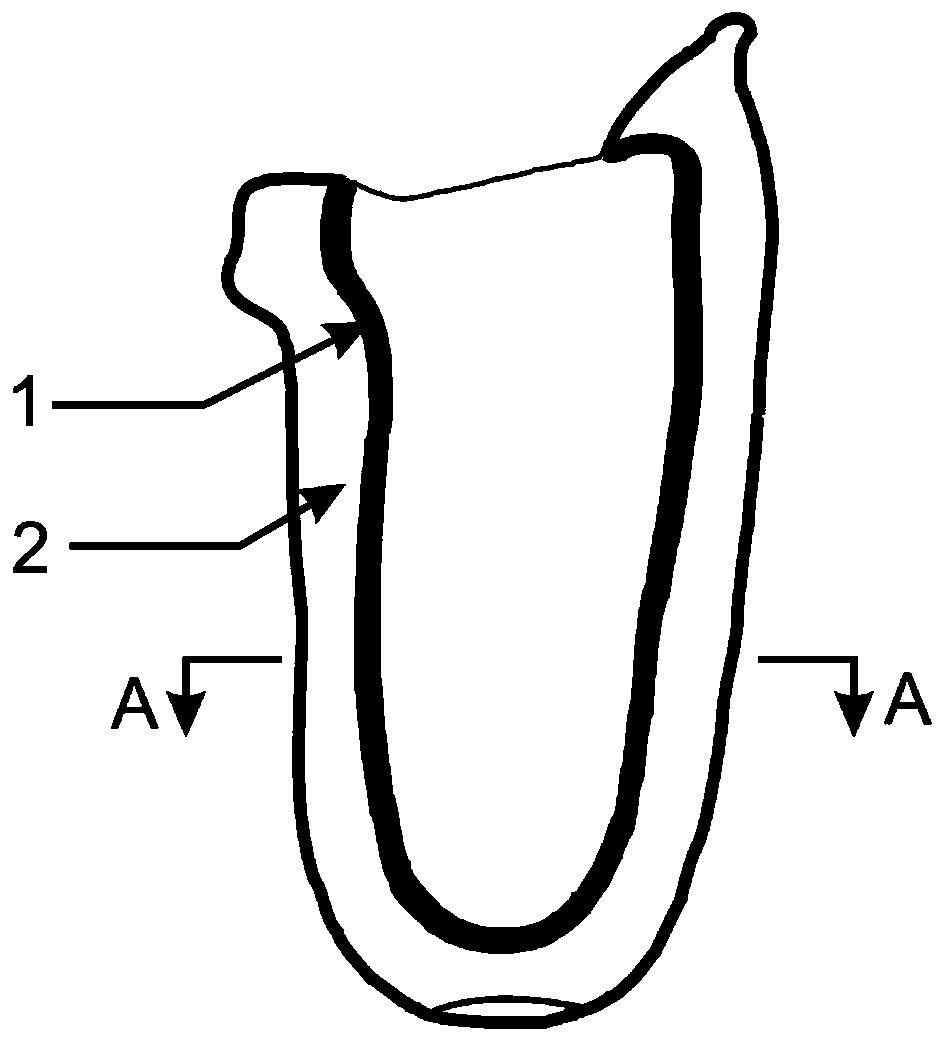

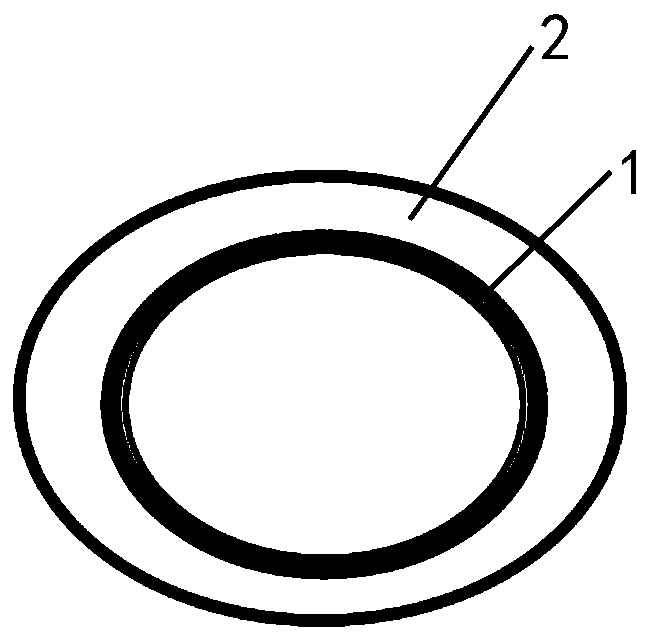

[0035]The structure and features of the present invention will be described in detail below in conjunction with the drawings and embodiments. It should be noted that various modifications can be made to the embodiments disclosed herein, therefore, the embodiments disclosed in the specification should not be regarded as limitations on the present invention, but only as examples of embodiments, and its purpose is to make the present invention The features of the invention are self-evident.

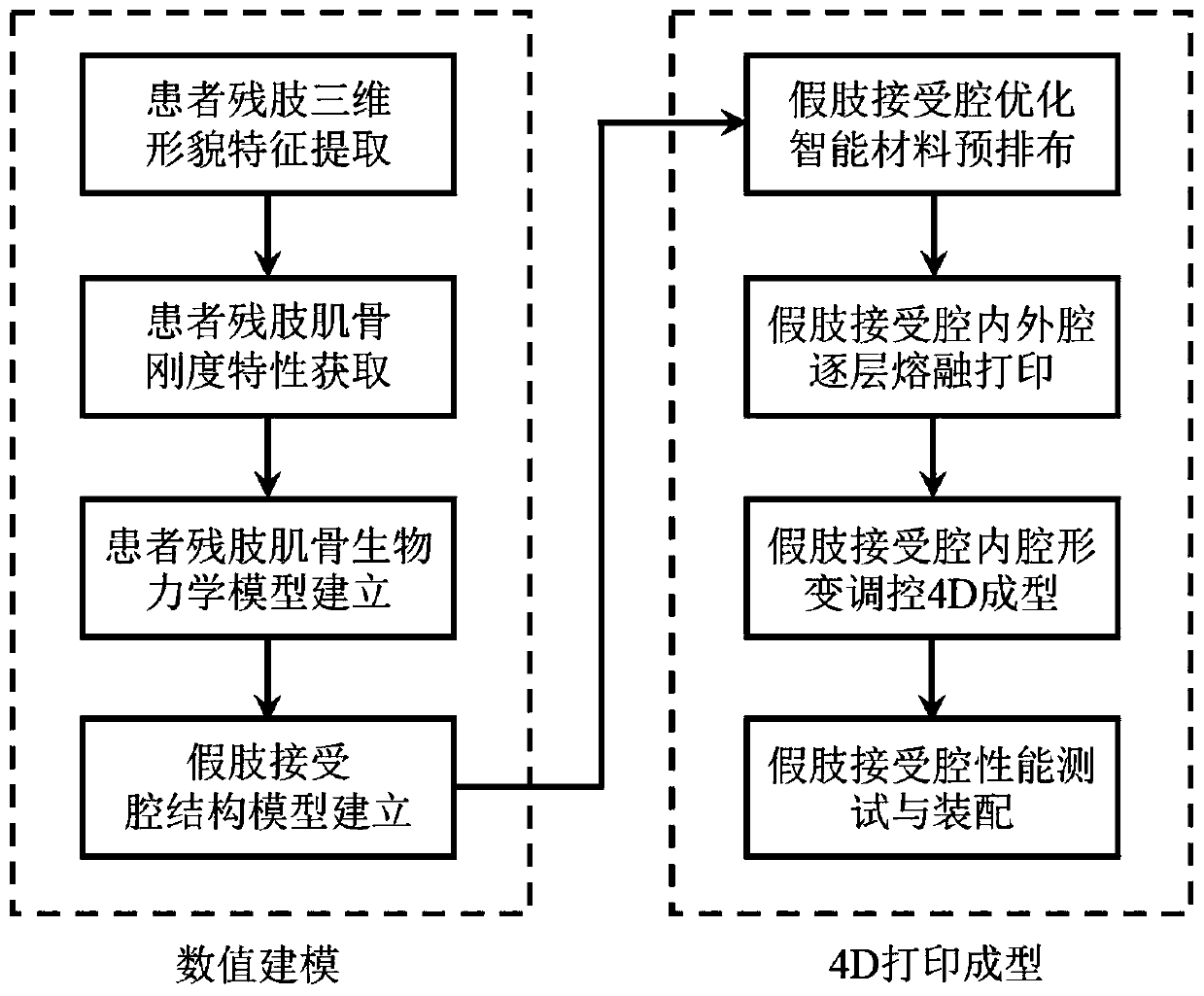

[0036] Such as figure 1 As shown, the present invention discloses a prosthetic socket 4D printing molding method with deformation control function, comprising the following steps:

[0037] 1) Use the human body 3D scanning system to obtain the 3D shape feature data of the wearer's residual limb, and establish a 3D point cloud model of the wearer's residual limb;

[0038] 2) Use the human musculoskeletal stiffness measurement equipment to sequentially record the stiffness characteristic dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com