Large-clamping-force machining device for hole in gate valve

A processing device and clamping force technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large processing volume, long processing cycle, and many processes, so as to improve work efficiency and workpiece processing accuracy High, high machine efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

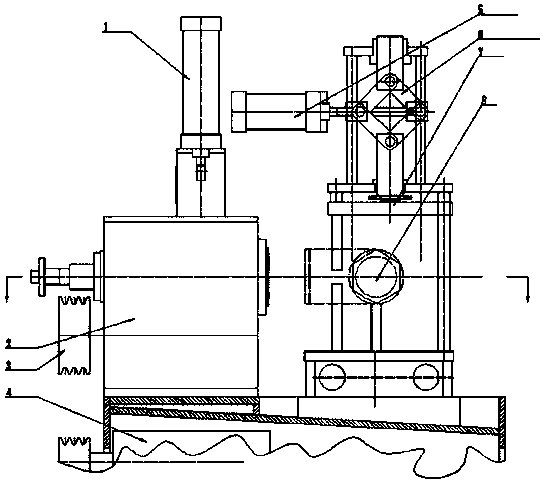

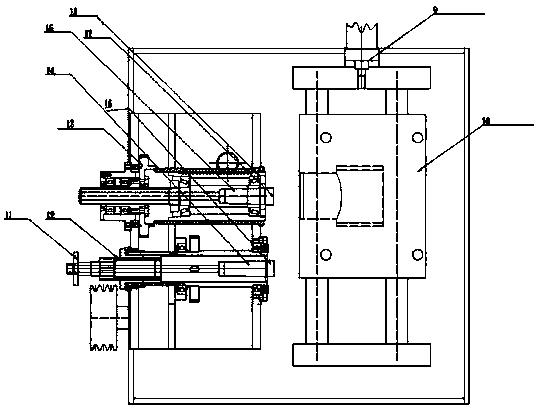

[0020] The reference signs shown in Fig. 1 and Fig. 2 are as follows: cylinder one 1, spindle box 2, pulley 3, motor 4, workpiece clamping cylinder 5, parallelogram booster mechanism 6, fixture 7, workpiece 8, cylinder two 9 , Two-station workpiece carriage 10, pawl 11, screw nut 12, gear 13, reaming spindle 14, reaming tap 15, milling cutter spindle 16, milling cutter 17, rack 18. Concrete implementation: a processing device with a large clamping force in the middle of a gate valve, mainly comprising a reaming wire spindle 14, a milling cutter spindle 16, a workpiece clamping cylinder 5, a parallelogram booster mechanism 6, 1 two-station workpiece carriage 10; the workpiece clamping cylinder 5 is in the middle of the machine tool; there is a parallelogram booster 6 on the right side of the workpiece clamping cylinder 5; the parallelogram booster can enlarge the cylinder The clamping force ranges from 2 tons to 5 tons, which solves the problem of increasing the pneumatic clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com