A protein crushing device

A technology for crushing equipment and proteins, which is applied in the fields of biochemical equipment and methods, biomass post-processing, peptide preparation methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

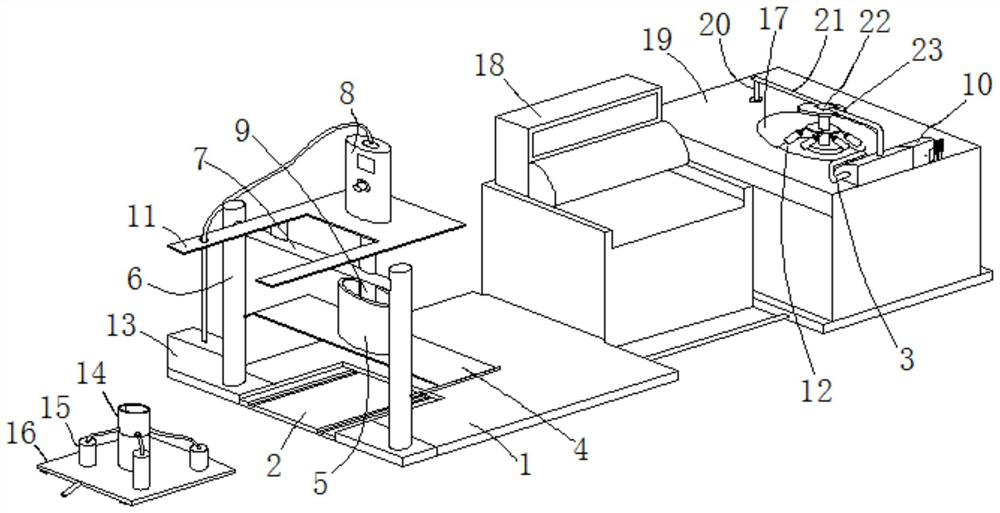

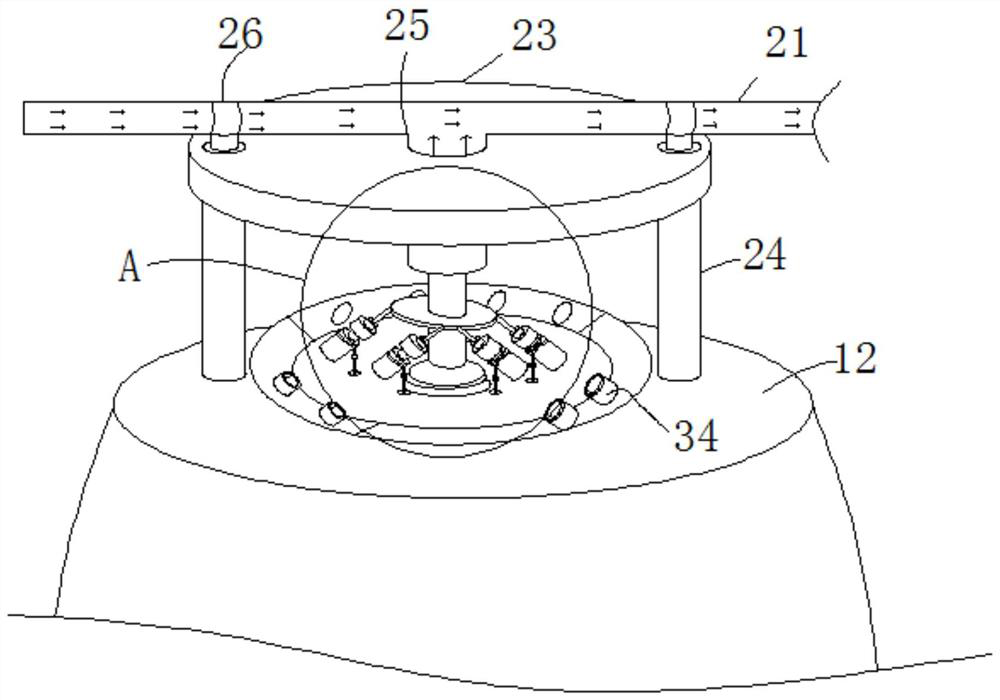

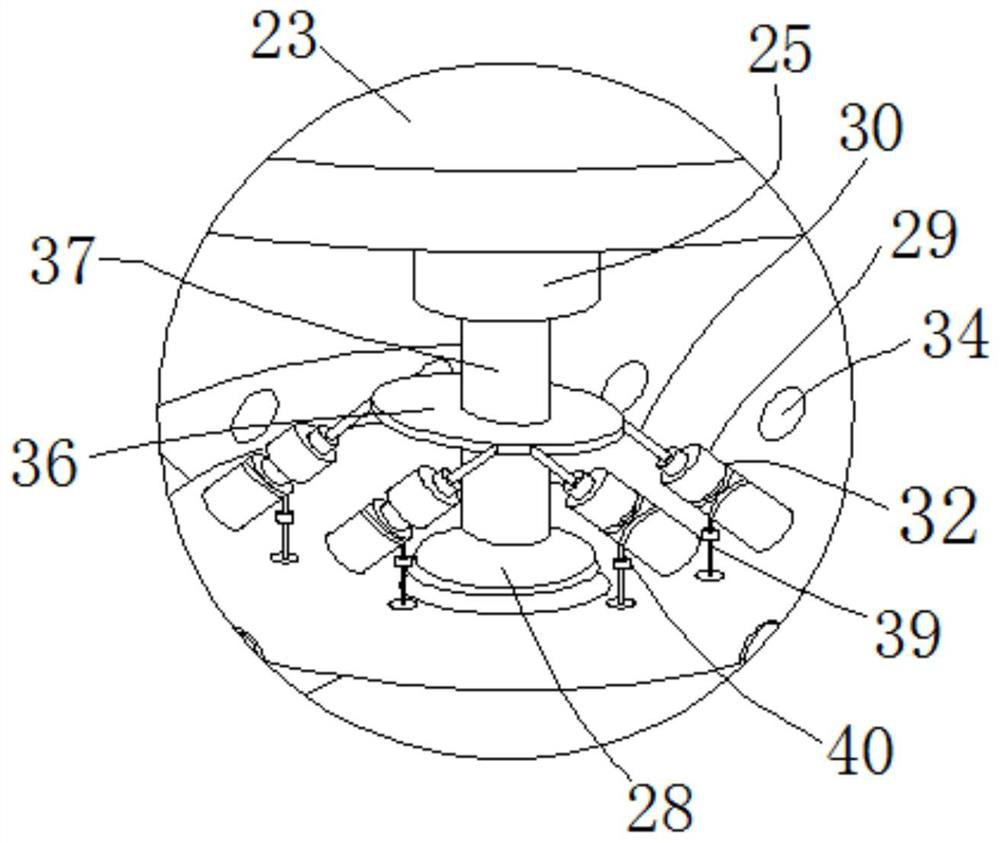

[0029] refer to Figure 1-7 , a kind of protein crushing equipment of the present invention, comprises cell crushing device and protein crushing device, wherein, protein crushing device comprises console 18, air pump 10, sealed tube 29, ultrasonic breaker 33 and test tube placement cylinder 34, console 18 and The air pump 10 is electrically connected, and the air pump 10 is a ventilation air source for blowing and sucking. connected, the other end is slidably inserted into the test tube placement cylinder 34, and the gas guide piston assembly connected to it is arranged on both sides of the push piston assembly, and the bubble mechanism is arranged on the periphery of the ultrasonic breaker 33 below the air guide piston assembly. There is a pushing assembly between the bubble rolling mechanism and the air guide piston assembly to push the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com