Highly rigid low water-absorbent PA/ABS alloy material and preparation method thereof

A low water absorption, alloy material technology, applied in the field of alloy materials, can solve the problems of low water absorption, bending and impact resistance, short molding cycle, insufficient rigidity, etc., to achieve good comprehensive performance, low water absorption, solve rigidity Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

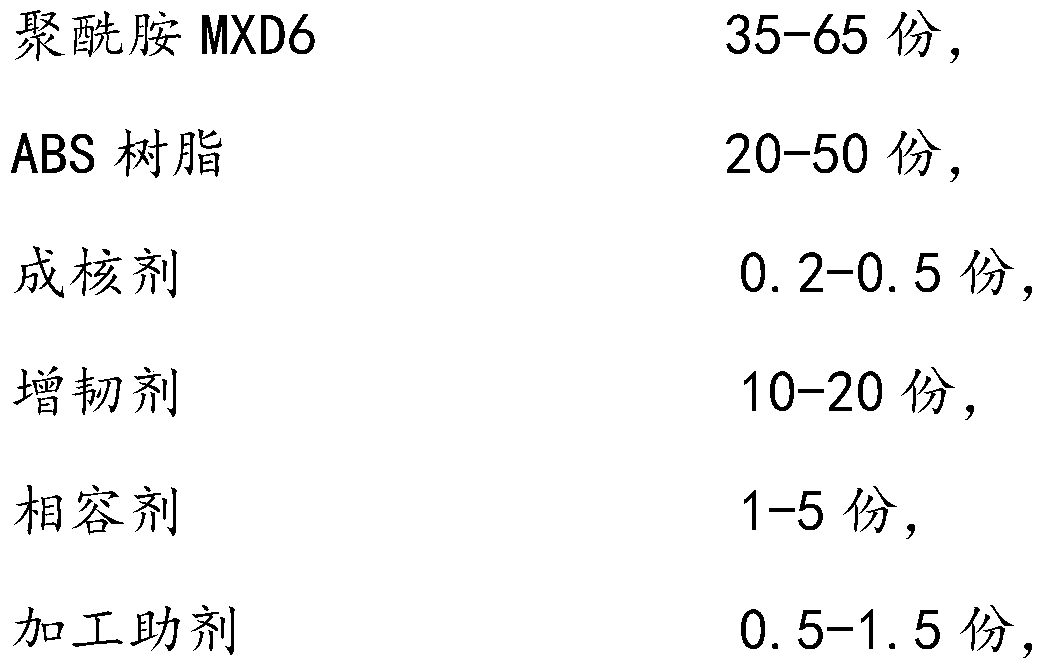

Method used

Image

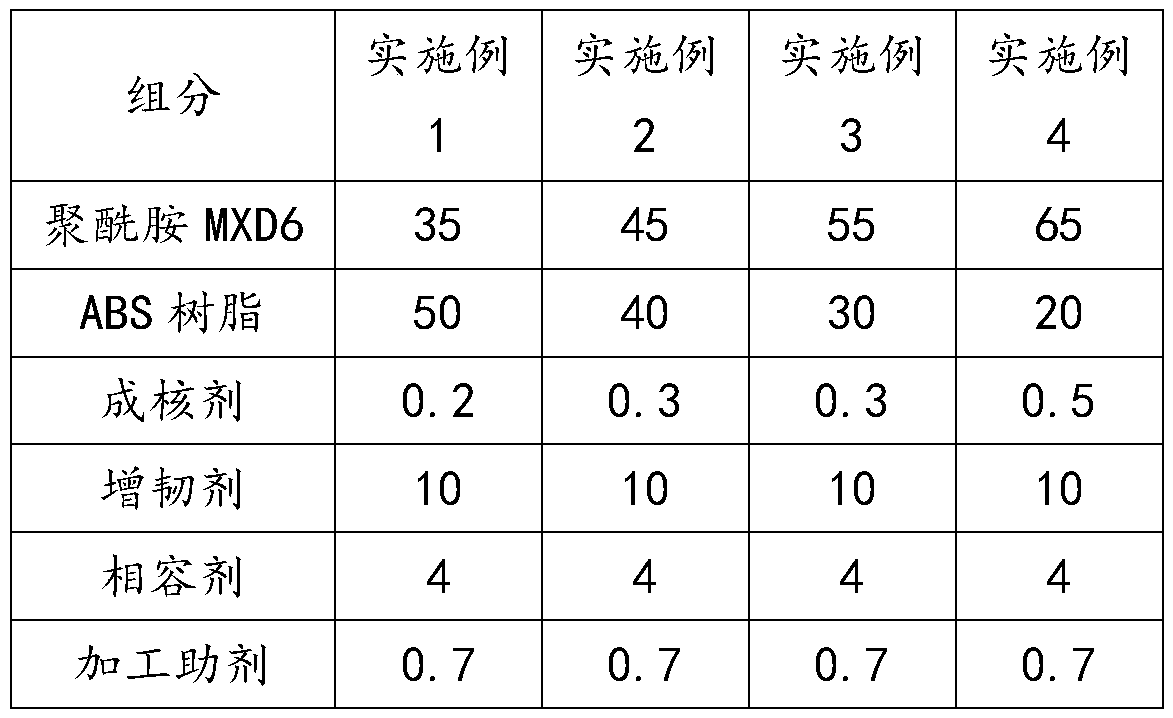

Examples

Embodiment 1

[0034] Taking Example 1 as an example, its preparation method comprises:

[0035] Step a, drying the polyamide MXD6 and ABS resin in a dehumidifier at 100°C for 6-8 hours, and controlling the moisture content to be less than 0.03%;

[0036] Step b, weighing the dried polyamide MXD6 and ABS resin, and toughening agent, compatibilizer, nucleating agent and processing aid according to the weight ratio, adding them to a high mixer and mixing for 2-5 minutes;

[0037] Step c. Send the mixed raw materials in step b into a twin-screw extruder for melting and plasticization, kneading and mixing, and finally extrude through the machine head, draw strands, cool, pelletize, and dry to obtain high-rigidity PA / ABS alloy material.

[0038] Wherein, the aspect ratio of the twin-screw extruder adopted is 40:1;

[0039] The screw speed is 350-400rpm;

[0040] The processing temperatures of each section of the twin-screw extruder are: the temperature of the first zone is 220-240°C, the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com