Bubbling bed reactor for inner circulation of a variety of catalysts, and hydrogenation method

A technology of ebullated bed reactor and catalyst circulation, which is applied in the petroleum industry, refining to remove heteroatoms, refining hydrocarbon oil, etc. It can solve the problems of less operation means, narrow range of fluid velocity adjustment, and affecting the hydrogenation effect of heavy oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

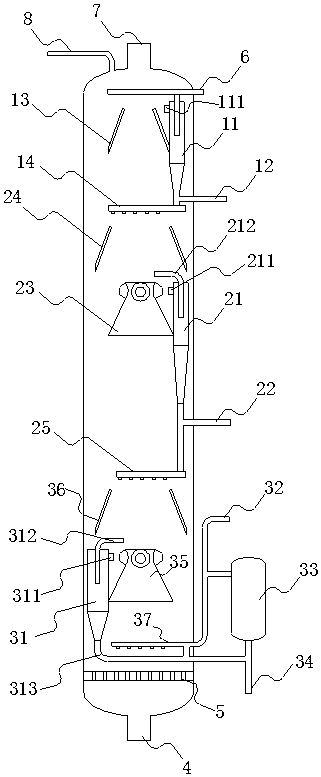

[0097] This embodiment adopts as figure 1 The ebullated bed reactor shown. The ebullated bed reactor is a pilot reactor with an inner diameter of 1m and a height of 23.1m, and the raw material is vacuum residue.

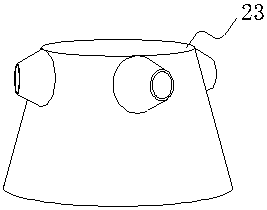

[0098] The ebullating bed reactor includes a top catalyst circulation zone, a middle catalyst circulation zone and a bottom catalyst circulation zone which are sequentially arranged from top to bottom.

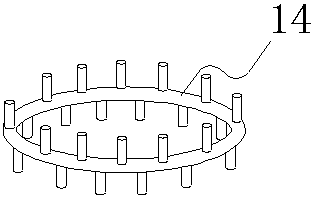

[0099] For the top stage catalyst circulation area, twelve first cyclone separators 11 ( figure 1 Only one is schematically drawn, and the other positions are the same as figure 1 The first cyclone separator in is substantially the same, except that twelve cyclone separators are arranged in a circle around the central axis of the reactor), and the lower catalyst outlet of the first cyclone separator 11 is connected to the first catalyst discharge port 12, connected with the first catalyst distributor 14 at the same time, the inlet 111 of the first cyclone separato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com