Large temperature difference central heating system using electric compression type heat pump

A compression heat pump and central heating technology, applied in hot water central heating systems, heating systems, and central heating, can solve problems such as changes in steam turbine operating conditions, complex construction levels, and changes in condenser vacuum, etc. Increase the heating capacity, ensure the heating effect, and reduce the difficulty of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

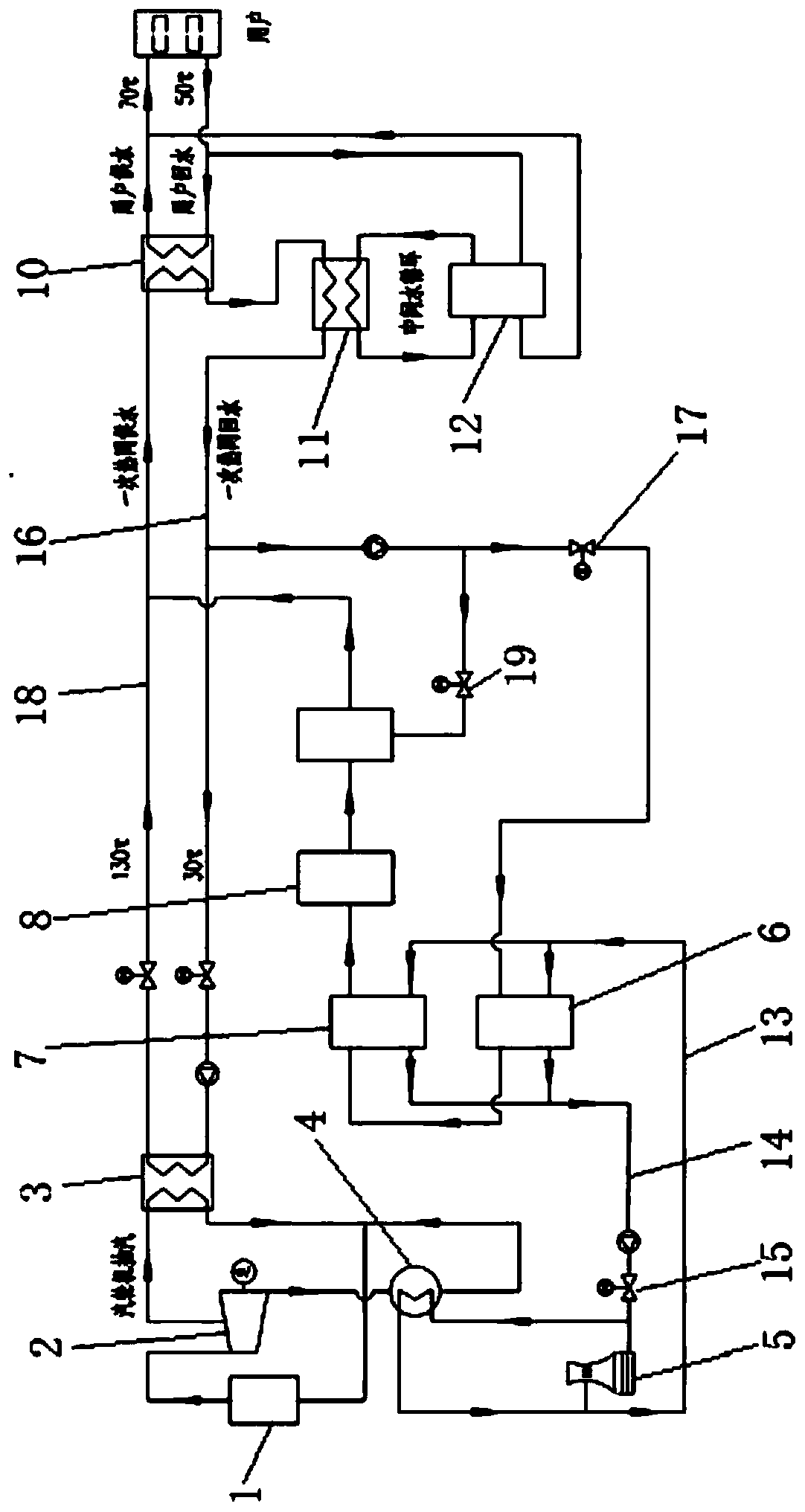

[0042] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] see figure 1 , the large temperature difference centralized heating system utilizing the electric compression heat pump provided by the present invention includes a steam turbine 2 connected to the boiler 1, and part of the medium-temperature and medium-pressure steam extracted by the steam turbine 2 is connected to the steam-water heat exchanger 3 through pipelines, The primary heating network supply water formed by heating the return water of the primary heating network through the steam-water heat exchanger 3 is then heat-exchanged by the first water-water heat exchanger 10 and then supplied to end users.

[0044] After the steam-water heat exchanger 3 releases heat, the condensed water is connected to the boiler 1 through pipes. The exhaust gas from the last stage of the steam turbine 2 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com