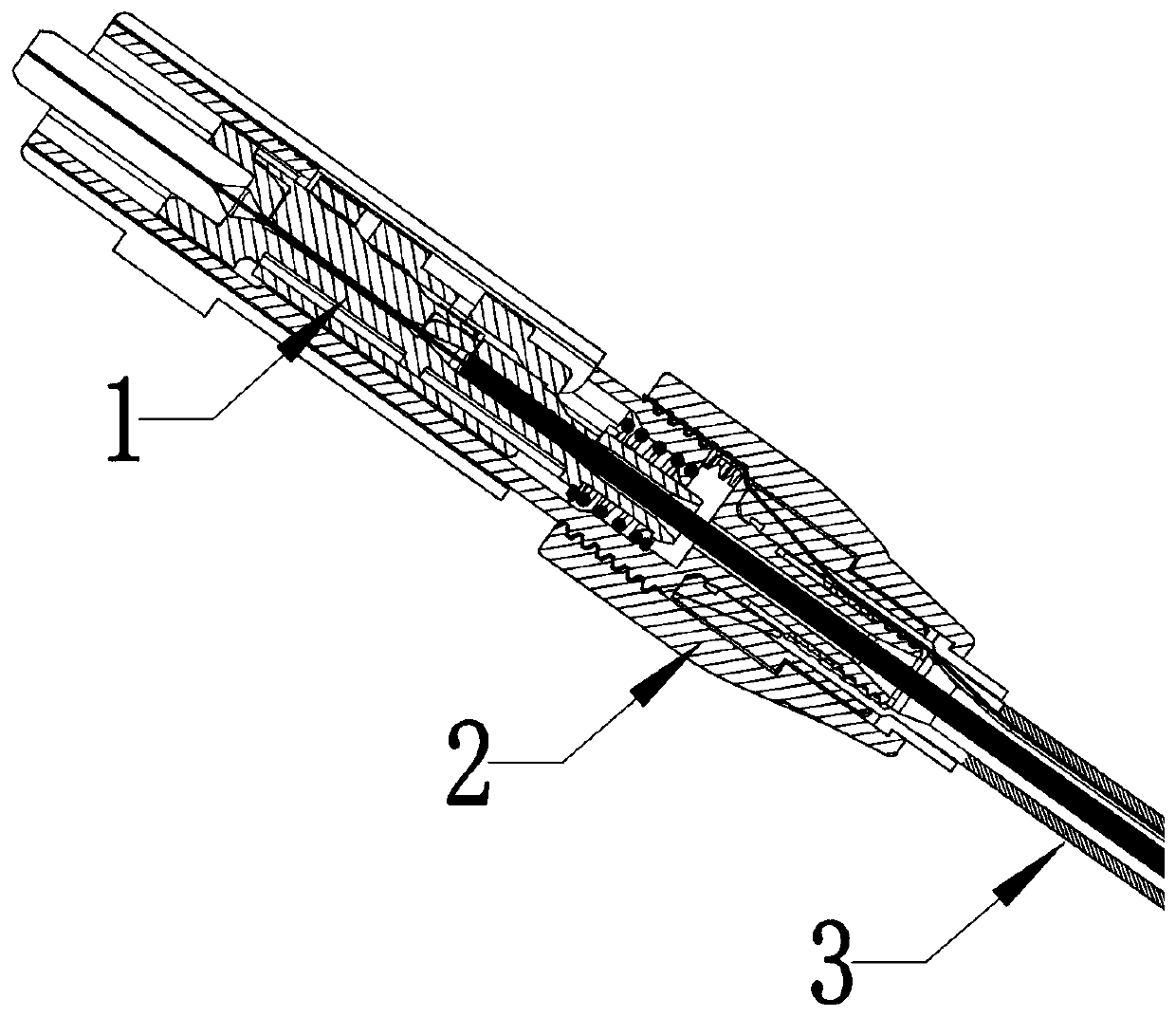

Loose-sleeve optical cable field assembly connector and a fixing assembly thereof

A technology for on-site assembly and fixation of components, applied in optical fiber/cable installation, fiber mechanical structure, etc., can solve the problems of small contact area, low hardness and strength of outer sheath, easy to break, etc., to increase contact area and increase roughness. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

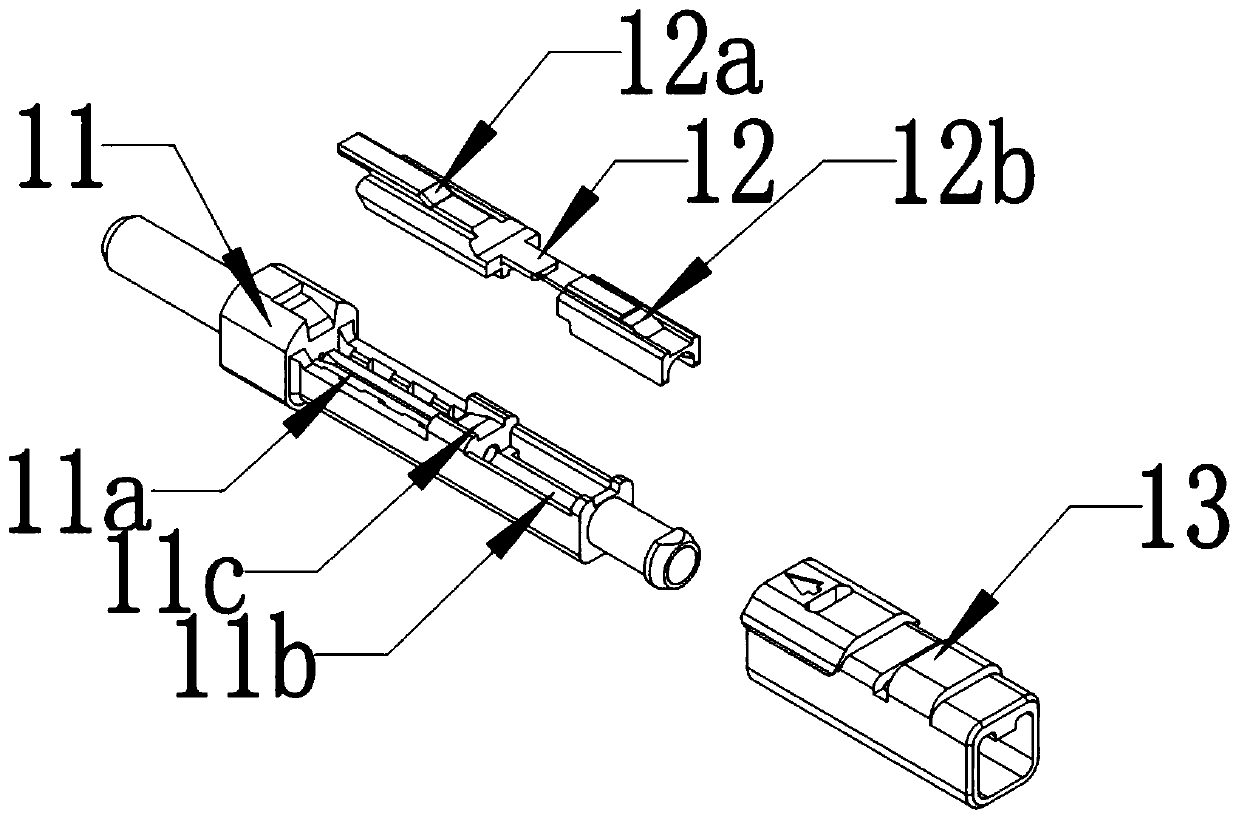

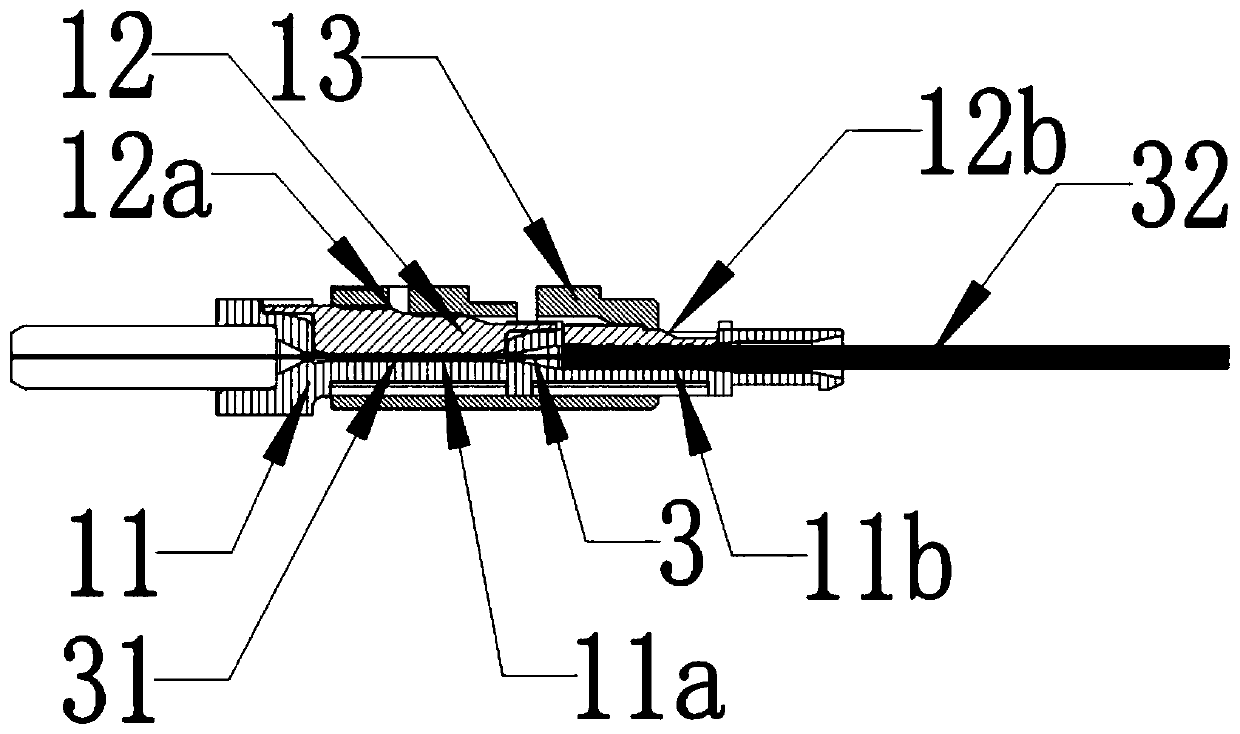

[0041] Embodiment 2: In this embodiment, the fixation component 2 is expanded and described;

[0042] The locking assembly is installed in the fixed housing 21 of the fixed assembly; the fixed assembly 2 includes a hollow fixed housing 21, a spacer sleeve 23 and an extruded sleeve 22; the spacer sleeve 23 and the fixed housing 21 are fixed by Structural occlusal connection; specifically, the limit sleeve 23 and the fixed housing 21 can be connected by any method of threaded engagement or snap connection; the extrusion sleeve 22 is arranged between the limit sleeve 23 and the fixed housing 21 , and cooperate with the limit sleeve 23 and the fixed housing 21; for fixing the reinforcing core 33 and the outer sheath 34 of the loose-tube optical cable 3; the tail of the fixed housing is provided with a first fixing part 21a, a second The fixed part 21b and the third fixed part 21c; and are connected sequentially in accordance with the order of the third fixed part 21c, the first fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com