Polyether composite thrust bearing

A technology of thrust bearings and polyether, applied in bearings, bearing components, shafts and bearings, etc., can solve the problems of the decline in load capacity and loss of load capacity of Babbitt alloy sliding bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail and completely below in conjunction with Examples and Comparative Examples.

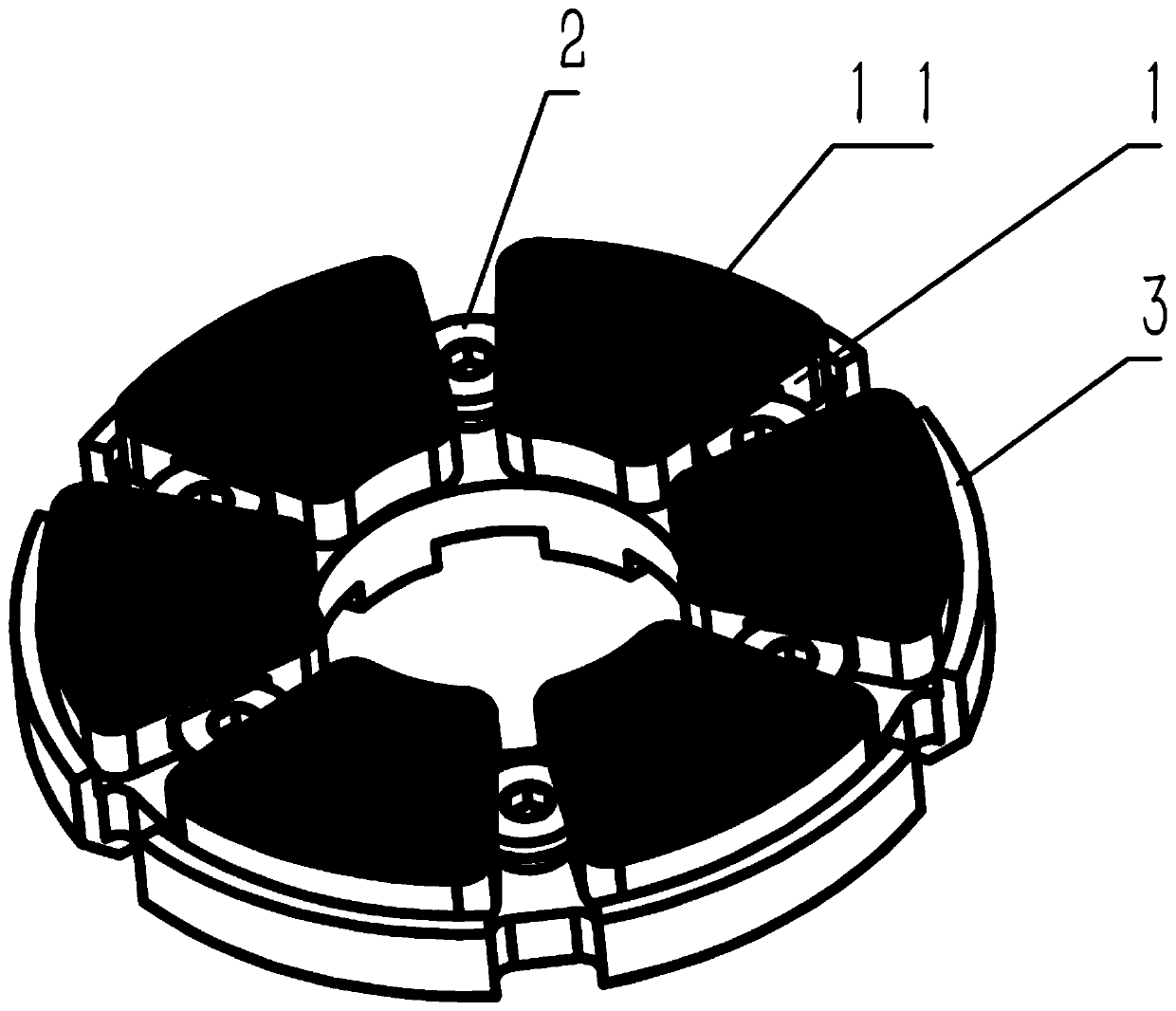

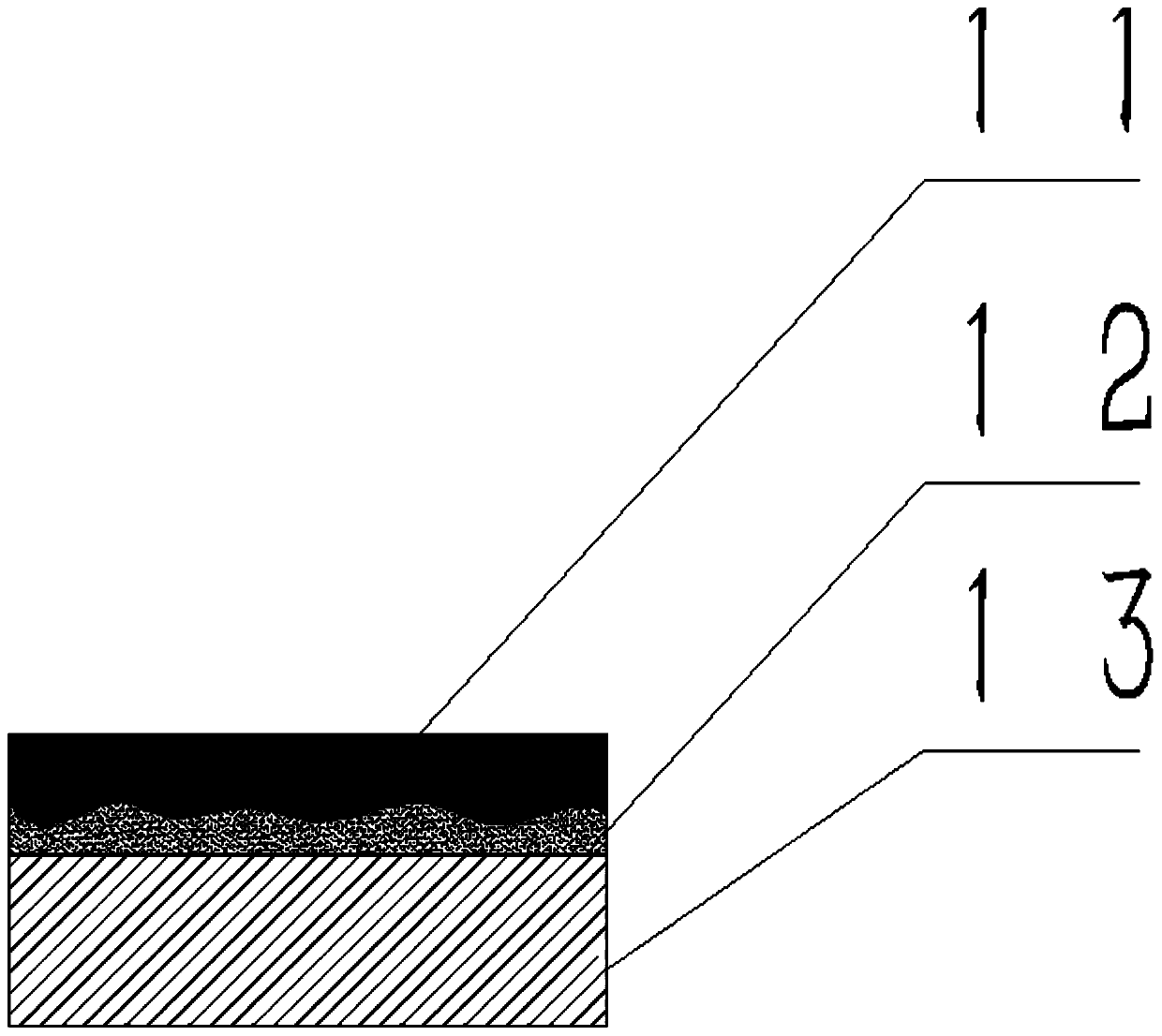

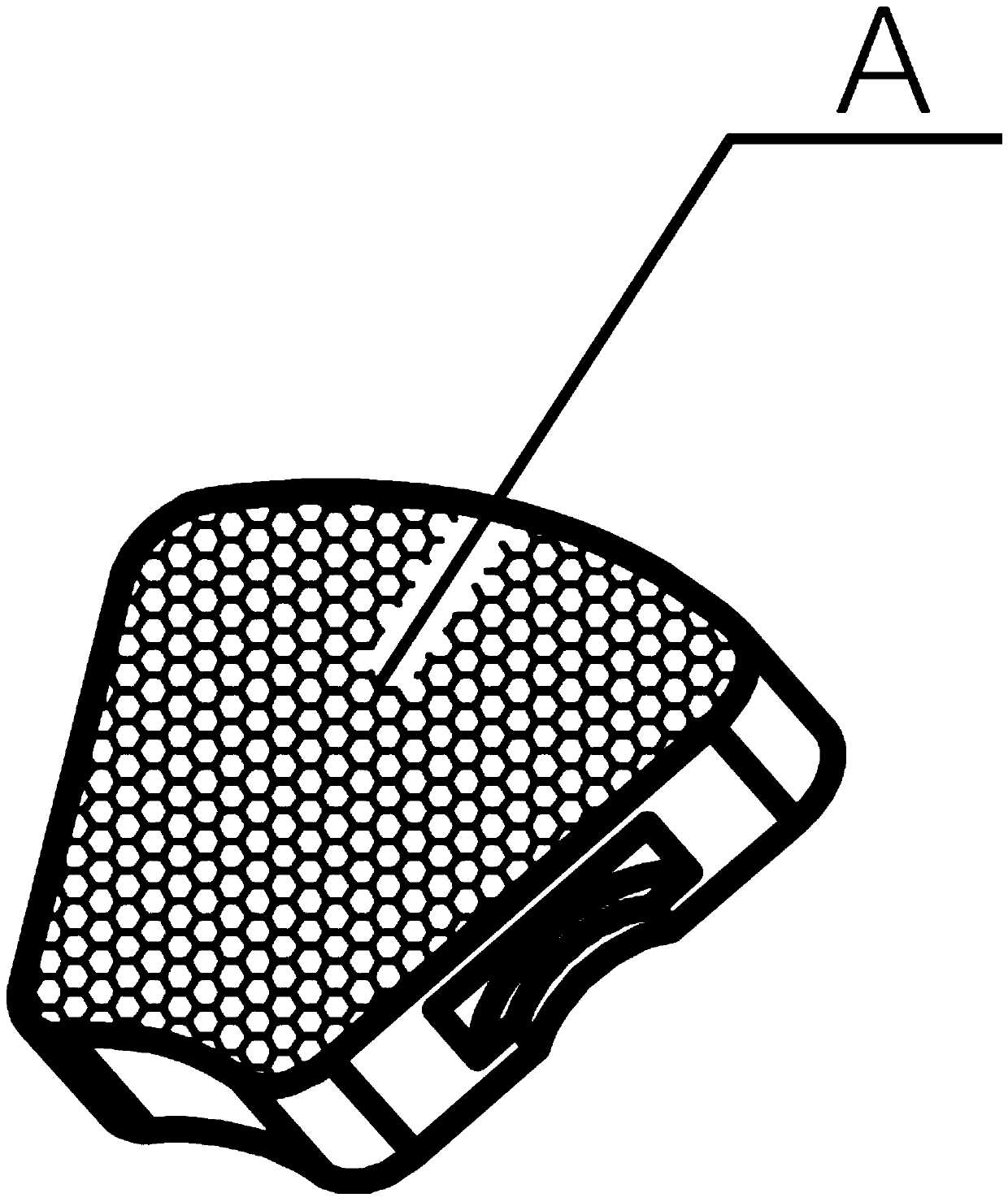

[0035] like Figure 1 ~ Figure 4 As shown, the polyether composite thrust bearing of this embodiment includes a pad 1, a limit screw 2 and a bearing body 3, and the limit screw 2 is movably connected with the pad 1 and the bearing body 3 respectively, and the pad 1 is at least three One, the pads 1 are evenly distributed on the bearing body 3 through the limit screws 2, the pads 1 sequentially include a pad base 13, and a metal transition layer 12 and a wear-reducing layer 11 arranged sequentially above the pad base 13; , The contact surface between the metal transition layer 12 and the anti-friction layer 11 is concavo-convex, and the anti-friction layer 11 is a PEEK coating.

[0036] In this embodiment, the metal transition layer 12 is fixed on the tile base 13 by means of vacuum sintering or electric spark sintering.

[0037] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com