A kind of nano-cellulose modified polylactic acid composite material and preparation method thereof

A technology of nanocellulose and composite materials, which is applied in the field of nanocellulose-modified polylactic acid composite materials and their preparation, can solve problems such as the interaction strength between nanocellulose and compatibilizer, and the notched impact strength of materials. It can greatly improve the problems such as improving the elongation at break and impact strength, improving the interfacial force and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

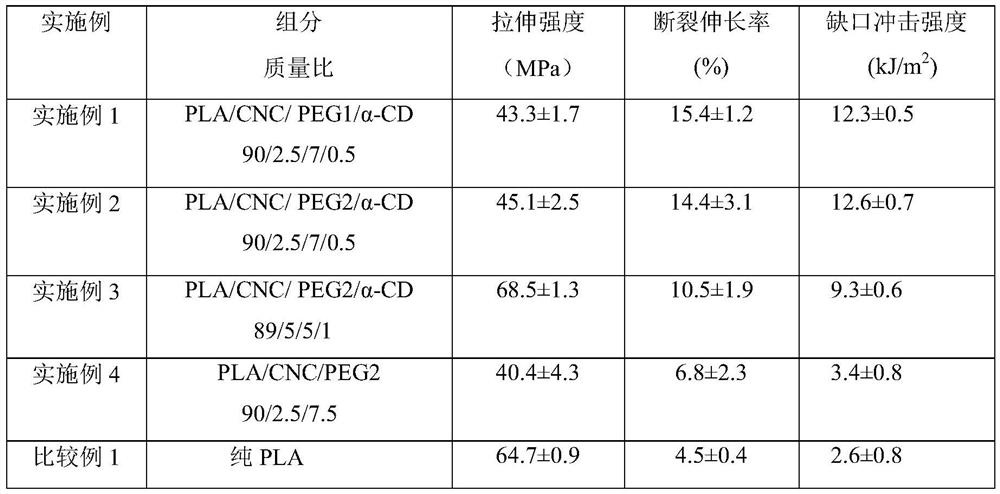

[0032] In this embodiment, the nanocellulose modified polylactic acid composite material includes the following components in weight percentage: 90% polylactic acid, 2.5% nanocellulose, 7% polyethylene glycol, and 0.5% cyclodextrin; its preparation method includes The following steps:

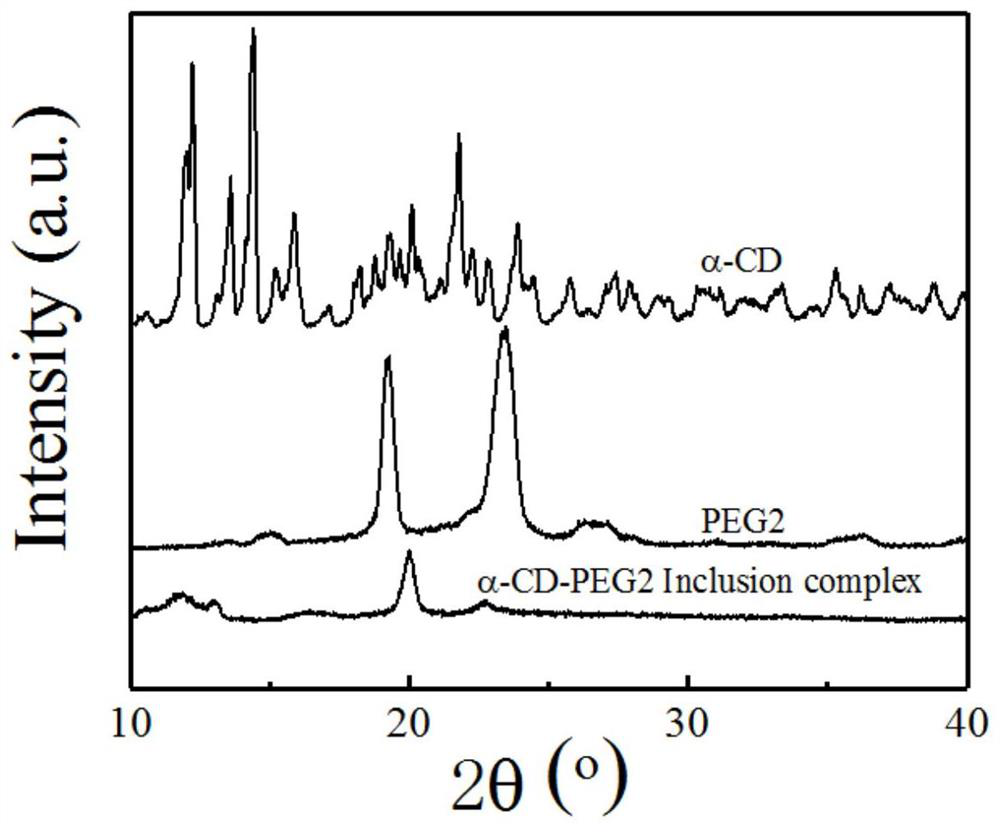

[0033] 1. Prepare respectively 15% α-cyclodextrin (α-cyclodextrin is 0.3g) aqueous solution and 10% polyethylene glycol-1000 (polyethylene glycol-1000 is 4.2g) with a weight concentration of 15% aqueous solution, and ultrasonically dispersed for 60 minutes; under the condition of keeping stirring, add polyethylene glycol-1000 aqueous solution drop by drop to α-cyclodextrin aqueous solution, after the dropwise addition, ultrasonically disperse for 60 minutes to obtain α-cyclodextrin-polyethylene glycol Ethylene glycol clathrate;

[0034] 2. Prepare an aqueous solution of nanocellulose (nanocellulose is 1.5 g) with a weight concentration of 0.5%, ultrasonically disperse it for 60 minutes, mix an...

Embodiment 2

[0038] In this embodiment, the nanocellulose modified polylactic acid composite material includes the following components in weight percentage: 90% polylactic acid, 2.5% nanocellulose, 7% polyethylene glycol, and 0.5% cyclodextrin; its preparation method includes The following steps:

[0039]1. Prepare the aqueous solution of 15% α-cyclodextrin (α-cyclodextrin is 0.3g) and the polyethylene glycol-2000 (polyethylene glycol-2000 is 4.2g) of 10% weight concentration respectively aqueous solution, and ultrasonically dispersed for 60 minutes; under the condition of keeping stirring, the polyethylene glycol-2000 aqueous solution was added dropwise to the α-cyclodextrin aqueous solution, and after the dropwise addition, ultrasonically dispersed for 60 minutes to obtain α-cyclodextrin-poly Ethylene glycol clathrate;

[0040] 2. Prepare an aqueous solution of nanocellulose (nanocellulose is 1.5 g) with a weight concentration of 0.5%, ultrasonically disperse it for 60 minutes, mix and...

Embodiment 3

[0044] In this embodiment, the nanocellulose modified polylactic acid composite material includes the following components in weight percentage: polylactic acid 89%, nanocellulose 5%, polyethylene glycol 5%, cyclodextrin 1%; its preparation method includes The following steps:

[0045] 1. Prepare the aqueous solution of 15% α-cyclodextrin (α-cyclodextrin is 0.6g) and the polyethylene glycol-2000 (polyethylene glycol-2000 is 3g) aqueous solution with a weight concentration of 10% respectively , and ultrasonically dispersed for 60 minutes; under the condition of keeping stirring, the polyethylene glycol-2000 aqueous solution was added dropwise to the α-cyclodextrin aqueous solution, and after the addition was completed, ultrasonically dispersed for 60 minutes to obtain α-cyclodextrin-polyethylene Diol clathrate;

[0046] 2. Prepare an aqueous solution of nanocellulose (nanocellulose is 3 g) with a weight concentration of 0.5%, ultrasonically disperse for 60 minutes, mix and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com