Hybrid-driven multi-stator multi-degree-of-freedom motor

A hybrid drive, degree-of-freedom technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of large size, few degrees of freedom, and complicated control, and achieve the effect of small size, many degrees of freedom, and wide use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

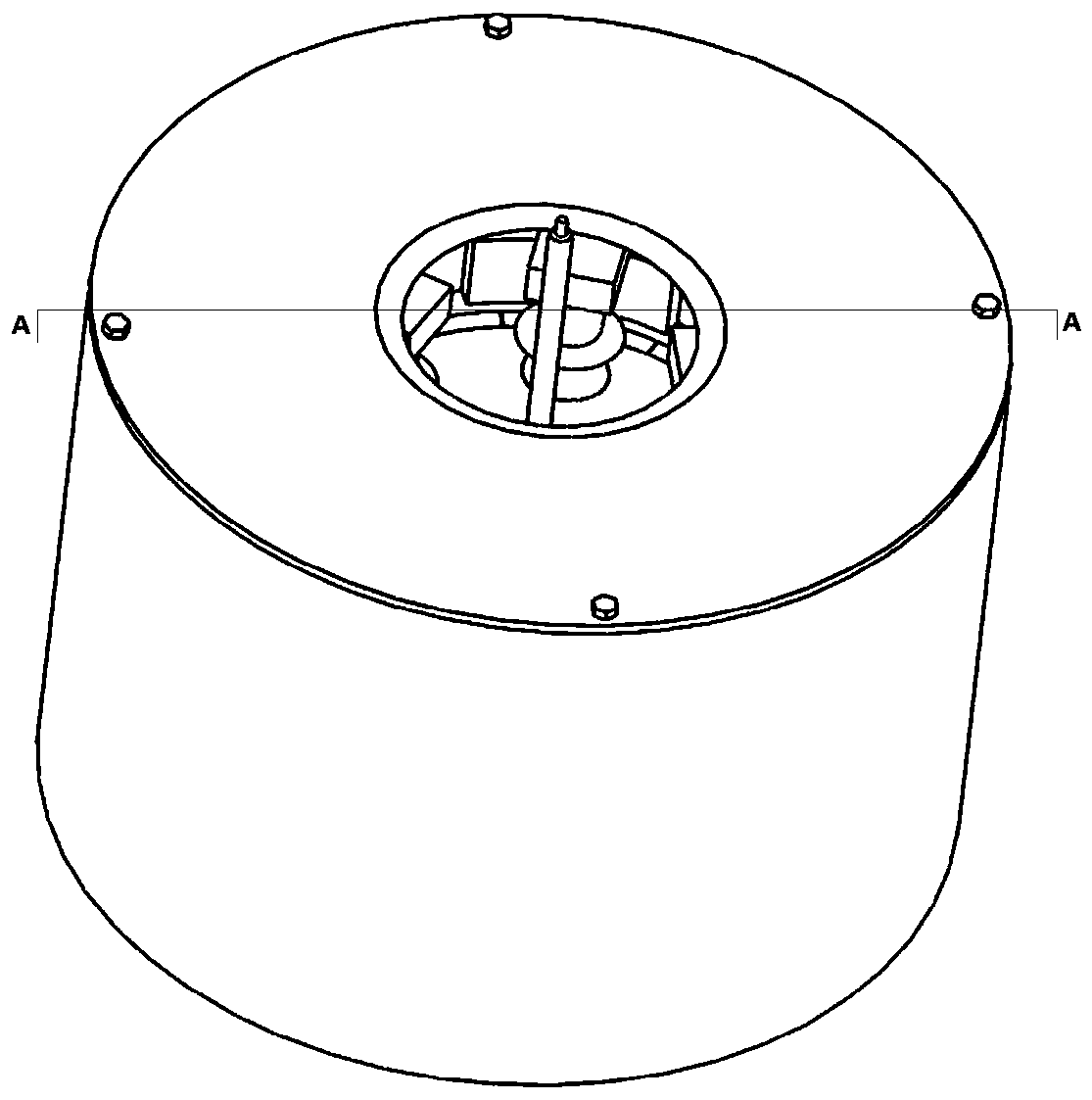

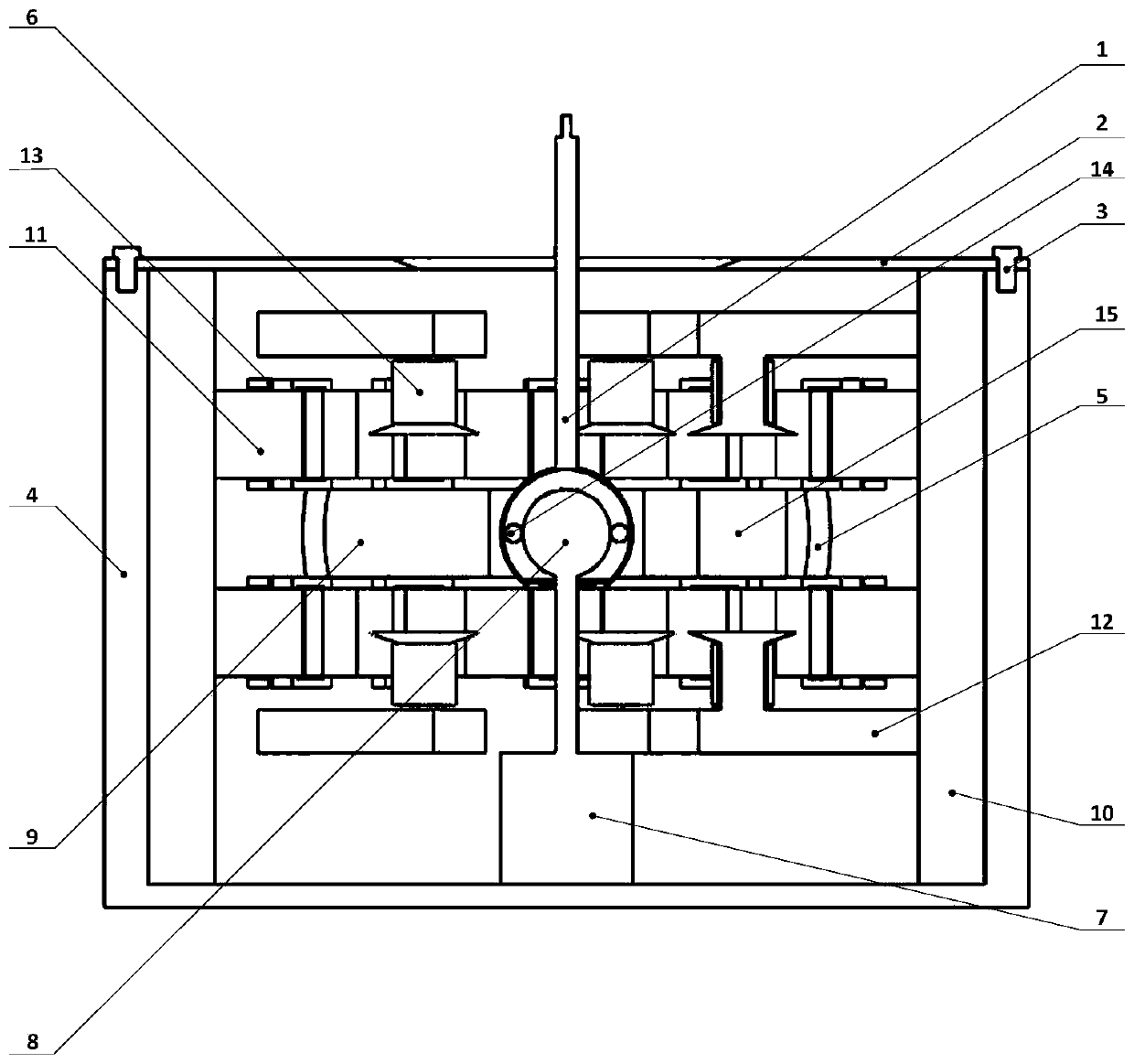

[0035] The accompanying drawings are only used to illustrate examples, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, some components in the accompanying drawings may be omitted, enlarged or reduced. Omissions, enlargements or reductions where present are understandable. Below in conjunction with accompanying drawing, this patent is described in detail.

[0036] As a specific embodiment of the present invention, the technical solution adopted by the present invention is: a hybrid drive type multi-stator multi-degree-of-freedom motor, including a housing 4, characterized in that it includes a stator and a rotor; the stator includes a circular cylindrical stator 11 and a telescopic stator 12. The annular cylindrical stator 11 is divided into upper and lower layers; separated in the middle (the two-layer stator will make the motor have better deflection performance); there are several pole shoes and stator windings 13 dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com