Wiring technology of saddle type electric fusion pipe fitting

A technology of electrofusion pipe fittings and saddle type, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., which can solve the problems of difficult manual operation, decreased production efficiency, and difficulty in ensuring the roundness of the inner wall, etc., and achieve product quality The effect of stability, high production efficiency and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

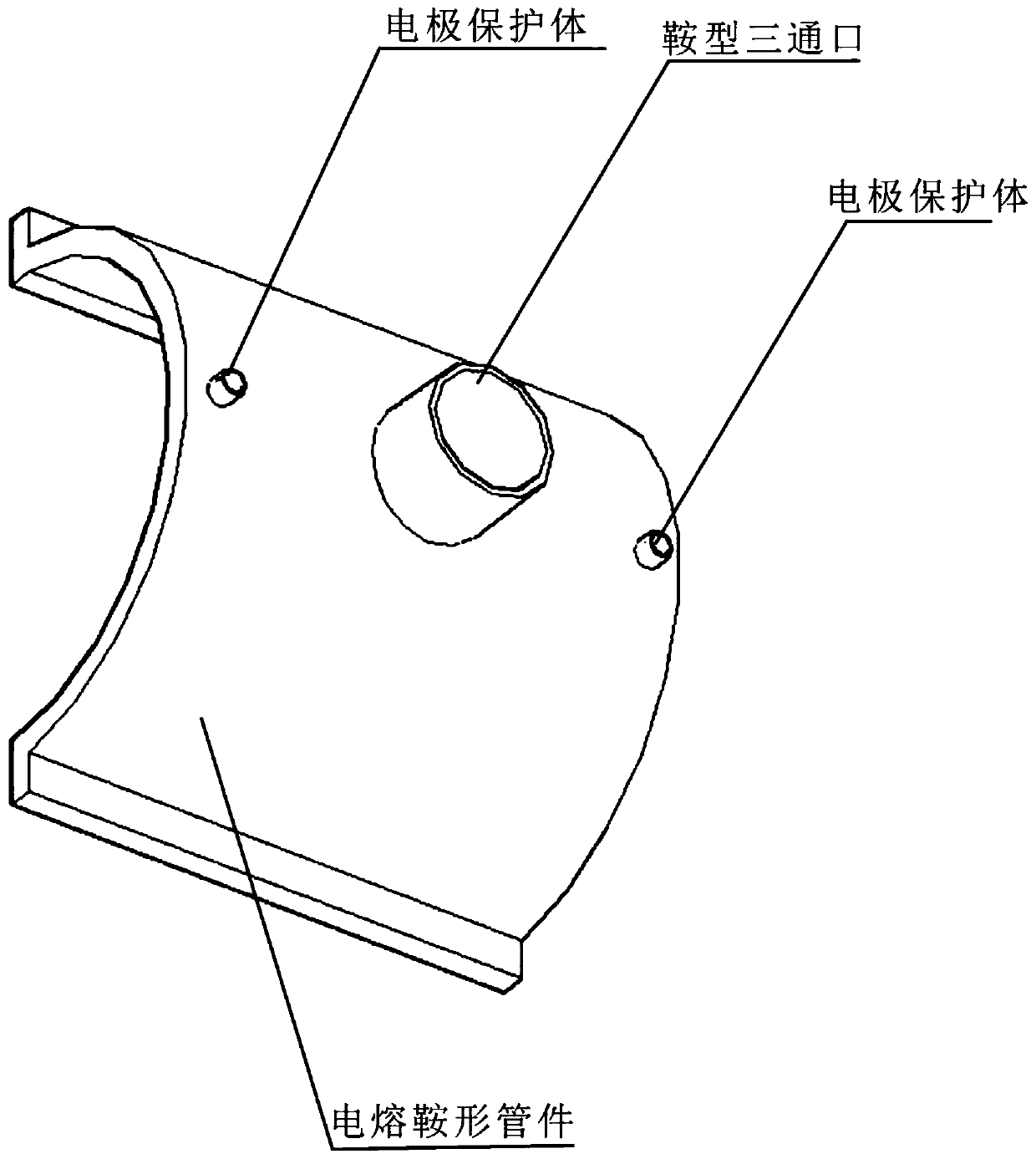

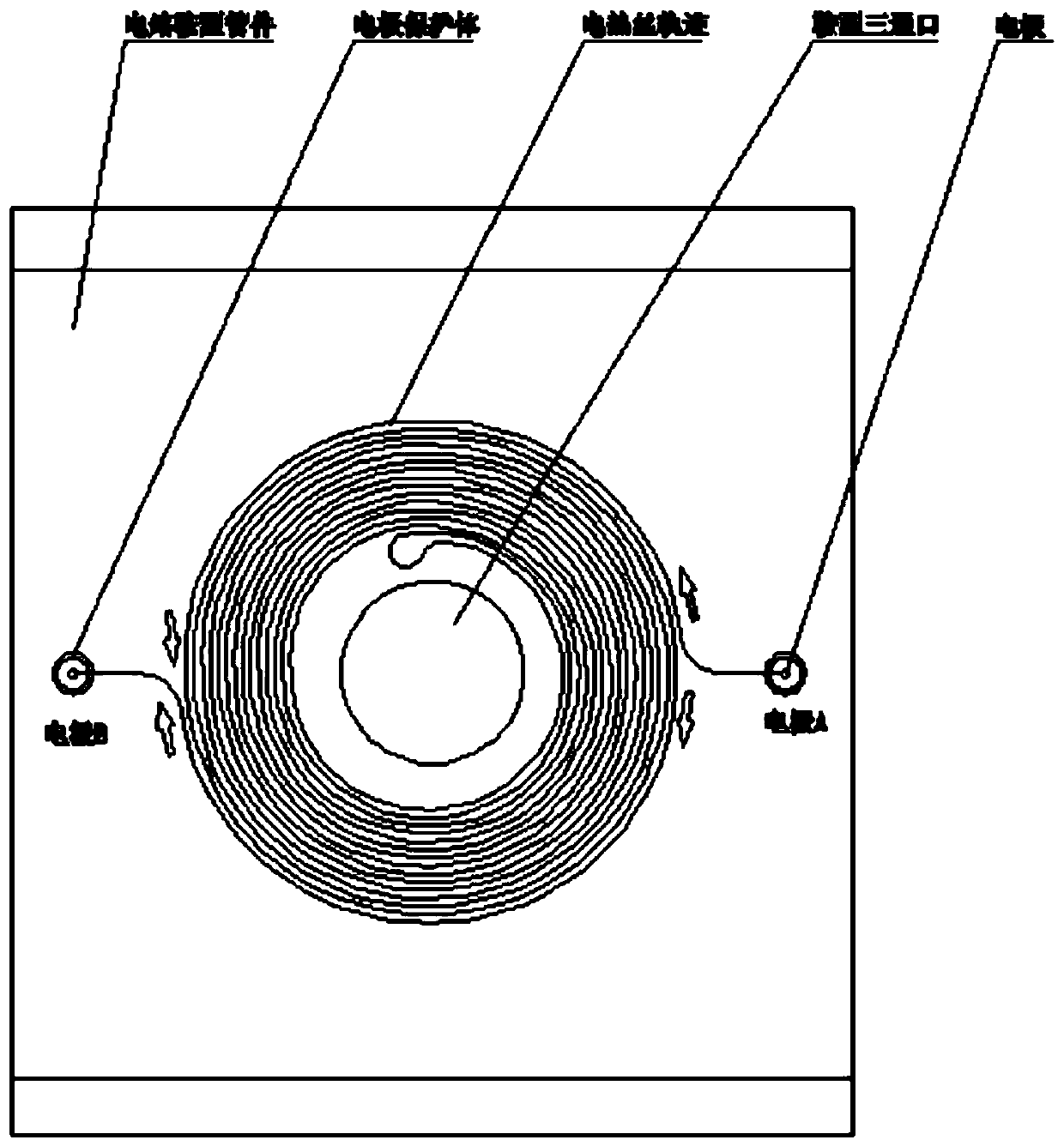

[0022] As shown in the figure, the present invention is further described:

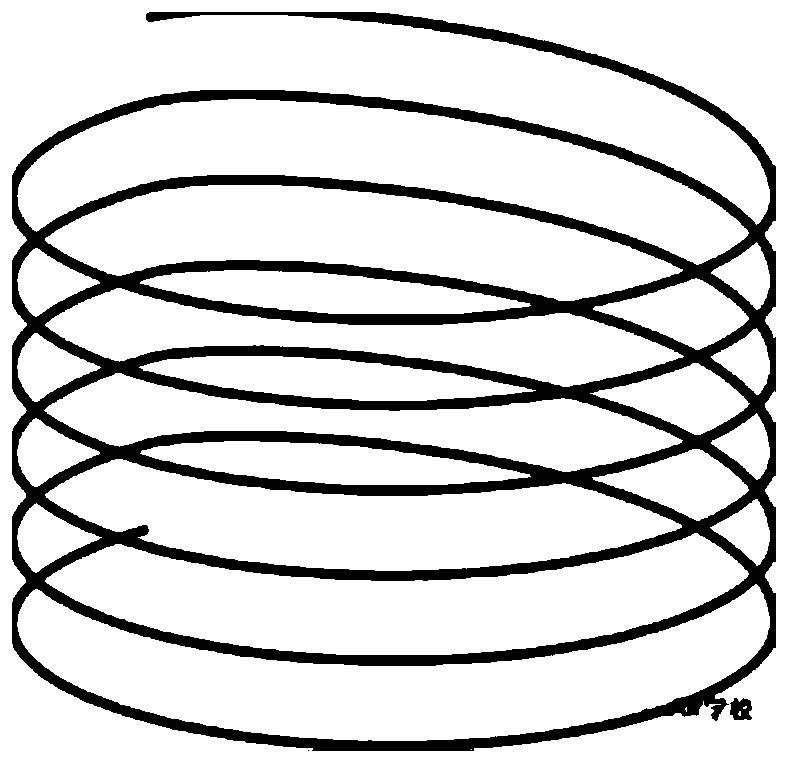

[0023] When using, first combine two semicircular saddle-shaped pipe fittings of the same specification to form a cylindrical pipe fitting, place it on the fixture of the wiring machine to tighten and fix it; then pass the resistance wire into the wiring knife and pull it out for a short distance , adjust the height difference between the top of the wiring blade and the top of the pressing part to obtain the required depth of the wiring groove, and fix the two with screws; then turn the saddle tube, and use a turning knife to turn the inside of the two saddle-shaped pipes at the same time , to remove the oxide layer on the inner wall of the pipe fitting, and adjust the roundness of the inner wall of the pipe fitting at the same time; carry out the wiring after turning, the wiring tool starts from the electrode A of the saddle-shaped electrofusion pipe fitting, first conducts a short section of wiring h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com