Battery frame lifting system and lifting method

A technology of lifting system and battery frame, which is applied in the direction of electric vehicles, electric power devices, circuits or fluid pipelines, etc. It can solve problems such as stagnation, insufficient stability and flexibility of lifting and replacement operations, and inconvenient operation of battery maintenance and replacement, etc., to achieve high efficiency. Replacement, easy mass production and post-maintenance, fast, stable and flexible lifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

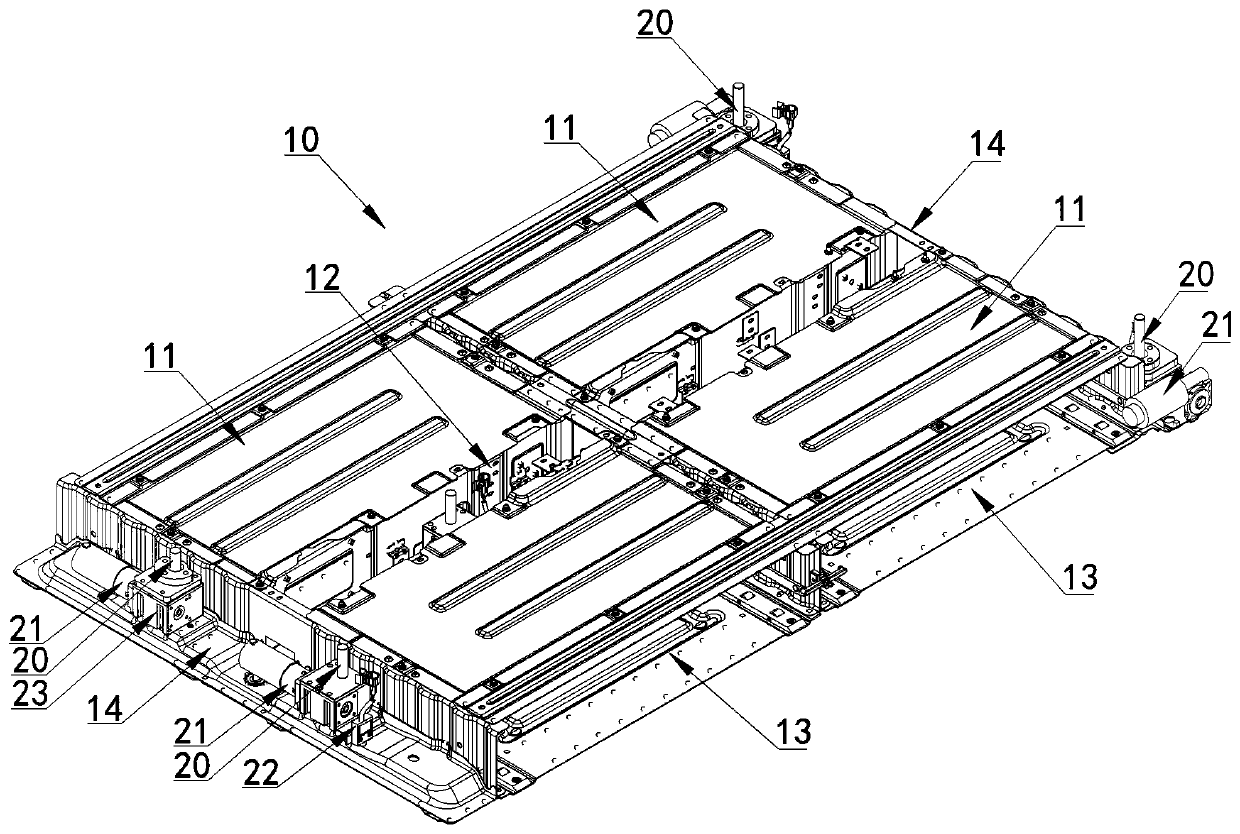

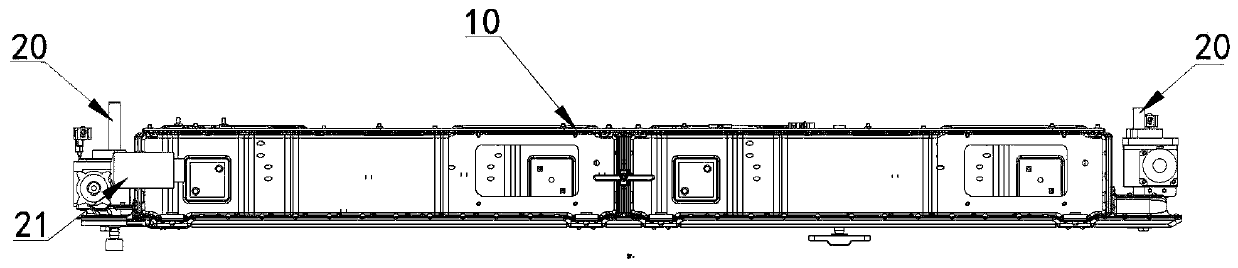

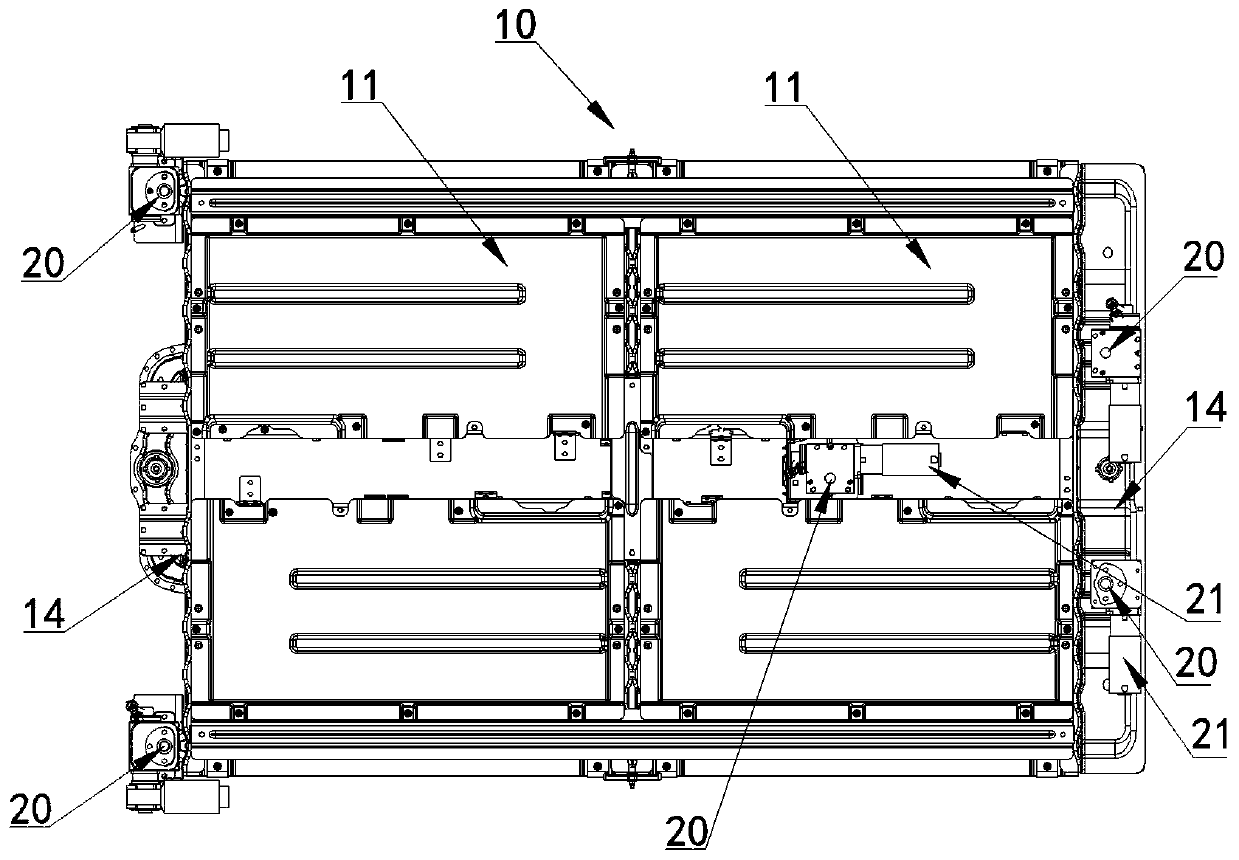

[0067] figure 1 , figure 2 , image 3 In the shown embodiment, a battery frame lifting system includes a battery frame 10, at least two lifting drive mechanisms are arranged between the battery frame and the vehicle body platform, and the lifting drive mechanisms each include a motor, and the motor is started to control the battery frame. The lower side of the vehicle body platform is raised or lowered, and at least one lifting drive mechanism is provided on the front and rear sides of the battery frame, and the motor is fixed to the battery frame or the vehicle body platform. The lowering drive mechanism also includes a reduction box arranged on the motor. The reduction box is provided with a worm gear linked with the output shaft of the motor and a worm cooperating with the worm gear. One of the platforms is fixed, the motor is fixed to the other of the battery frame and the body platform, and the motor is activated to move the motor up and down the worm. Hall sensors ar...

Embodiment 2

[0070] Figure 4 In the shown embodiment, a plurality of lifting drive mechanisms adopt electric push rods 30; the electric push rods 30 are driven and controlled by motors that drive the electric push rods, and the motors are activated to make the electric push rods expand and contract to realize the up and down movement of the battery frame; The rod is connected and fixed with the body platform of the new energy electric vehicle, and the top of the electric push rod and / or the top of the worm gear is connected and fixed with the battery frame 10 . An electric push rod is respectively arranged on the outside of the two ends of the battery frame, and two electric push rods are respectively arranged at the middle position of the ends of the battery frame; an electric push rod is arranged in the middle of the battery frame between the four battery single frames. Others are identical with embodiment 1.

Embodiment 3

[0072] Figure 5 , Figure 6 , Figure 7 , Figure 8 In the illustrated embodiment, a lifting method for a battery frame lifting system includes the following lifting steps:

[0073] 7-1 Judging whether the instrument panel button signal 40 is detected, if there is a button signal, then enter the next execution step, if there is no button signal, return to continue judging whether the instrument panel button signal is detected;

[0074] 7-2 When there is a key signal, the controller wakes up 41;

[0075] 7-3 Determine the state of the battery frame, and process the battery frame in the pre-rising state 50 and in the pre-falling state 60 respectively;

[0076] 7-4 In the above step 6-3, if it is judged to be in the pre-rising state, drive the lifting drive mechanism in one of claims 1 to 5 to control the battery frame to rise 51;

[0077] 7-5 Detect the PMM signal 52 sent by the lifting drive mechanism;

[0078] 7-6 Determine whether the maximum stroke difference ≥ 20mm53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com