Coal seam advanced fracturing C-shaped furnace method for strengthening the chemical reaction of underground coal gasification

A technology of underground gasification and chemical reaction, which is applied in earthwork drilling, boreholes/well components, and mining fluids, etc. It can solve problems such as high oxygen content, lower gas quality, and groundwater pollution, and achieve enhanced chemical reactions and increased The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

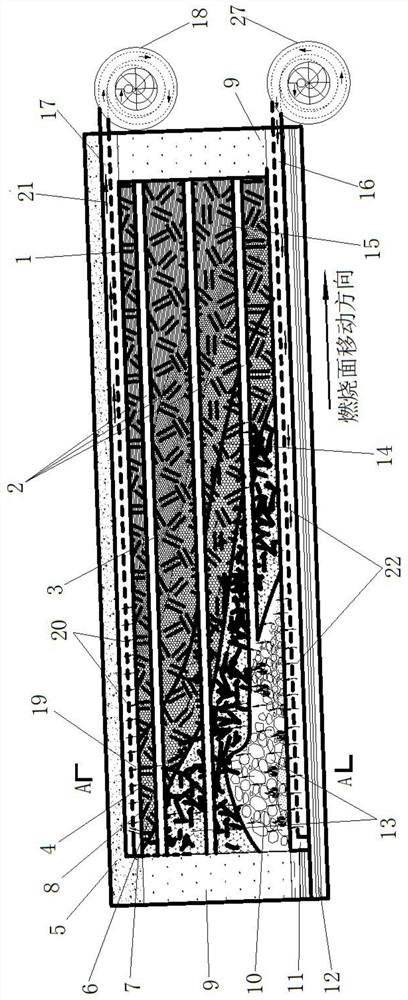

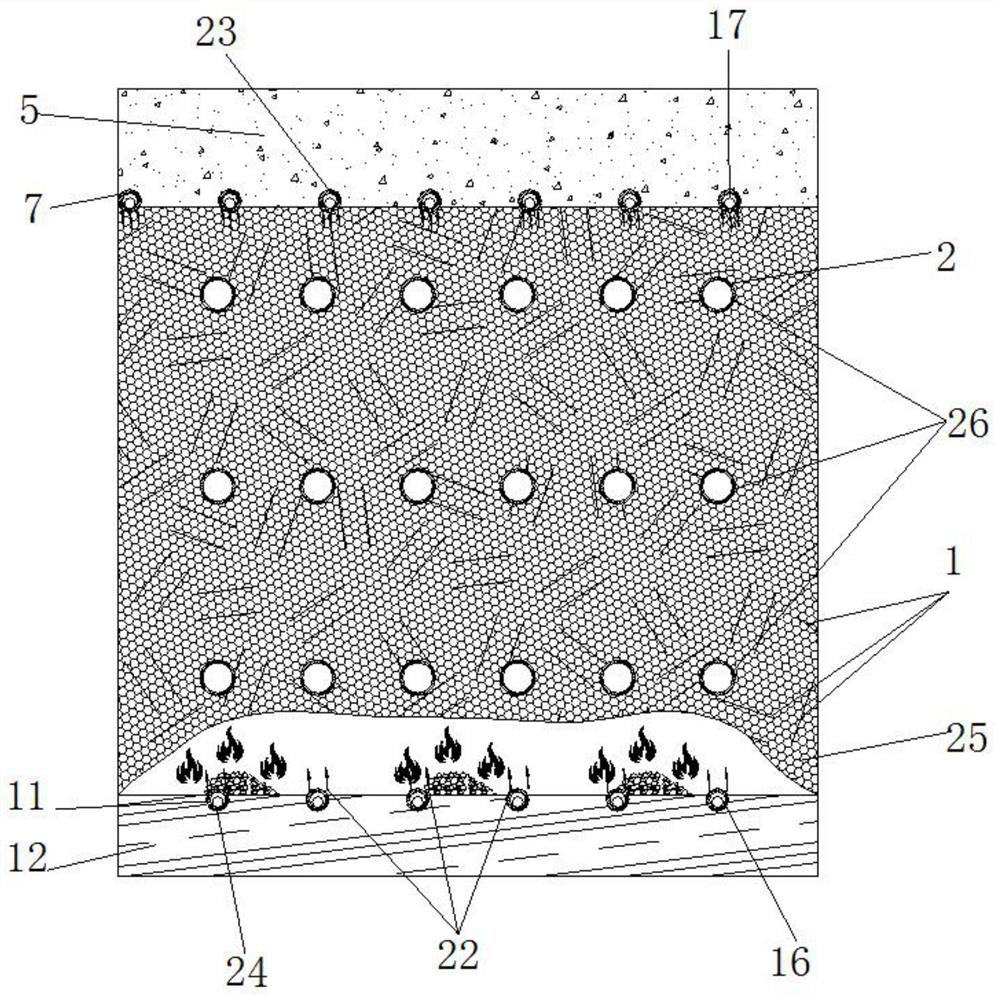

[0021] Such as Figure 1 to Figure 4 As shown, a coal seam advanced fracturing C-shaped furnace method for strengthening the chemical reaction of underground coal gasification comprises the following steps:

[0022] Step 1: drill a plurality of hydraulic fracturing boreholes 2 along the direction (in the case of non-horizontal coal seams) in the coal seam 25 between the immediate top 5 and the immediate bottom 12 in the gasifier area, and A plurality of hydraulic fracturing boreholes 2 are installed with fracturing drilling protection sleeves 26 one by one to support the hydraulic fracturing drilling 2; the drilling diameter of the hydraulic fracturing drilling 2 and the spacing of the drilling holes in the strike and coal seam height directions are based on The actual situation is determined in detail. As a preference, the fracturing drilling protection sleeve 26 is a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com