A scroll water vapor compressor system and working method using water spray lubrication

A compressor system and scroll compressor technology, applied in the field of scroll water vapor compressor systems, can solve the problems of difficulty in ensuring the strength of the movable scroll, large temperature rise, inability to cool down, etc., so as to improve cooling efficiency, Guaranteed compression efficiency and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is further elaborated:

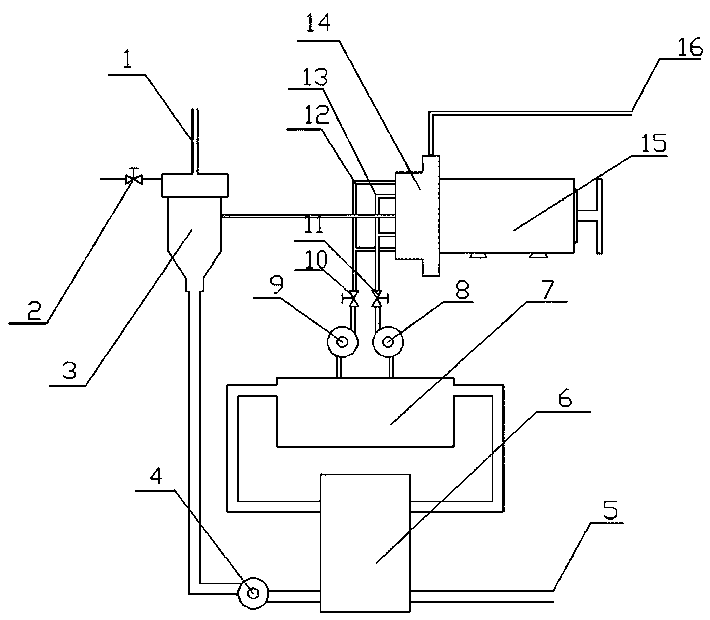

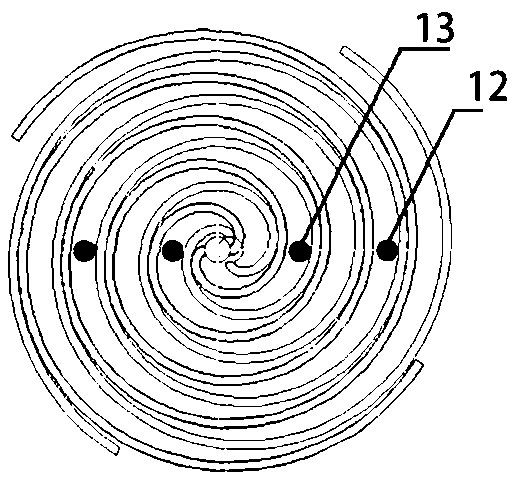

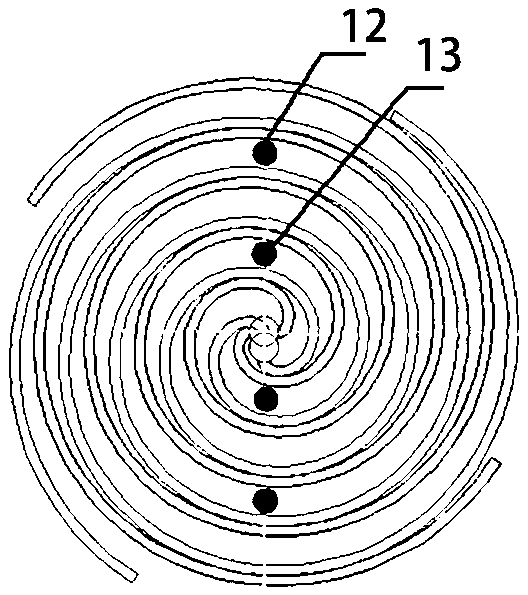

[0021] Such as figure 1 As shown, the scroll water vapor compressor system using water spray lubrication consists of compressed water vapor exhaust port 1, manual exhaust valve 2, gas-liquid separator 3, water pumps 4, 8, 9, water inlet 5, heat exchange device 6, water tank 7, electromagnetic valve 10, 11, outer compression chamber spray pipeline 12, inner compression chamber water spray pipeline 13, static scroll disk 14, scroll compressor 15, steam inlet 16; the static The scroll disk 14 is arranged coaxially with the cavity of the scroll compressor 15 . Such as figure 2 , 3 As shown, according to the size of the scroll 14, four water injection ports are uniformly opened along the two diameter directions perpendicular to each other. In the radial direction, the water injection ports located on the inner side correspond to the inner compression chamber of the scroll compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com