High-speed centrifugal compressor based on gas suspension

A centrifugal compressor and high-speed centrifugal technology, which is applied to parts of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc., can solve the problem of poor stability of the bearing-rotor system, affect the service life of the motor, and reduce the use of the motor Efficiency and other issues, to achieve high equipment conversion efficiency, long product life, and improve the effect of rotor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it can be understood that the following specific embodiments are only preferred technical solutions of the present invention, and should not be construed as limiting the present invention.

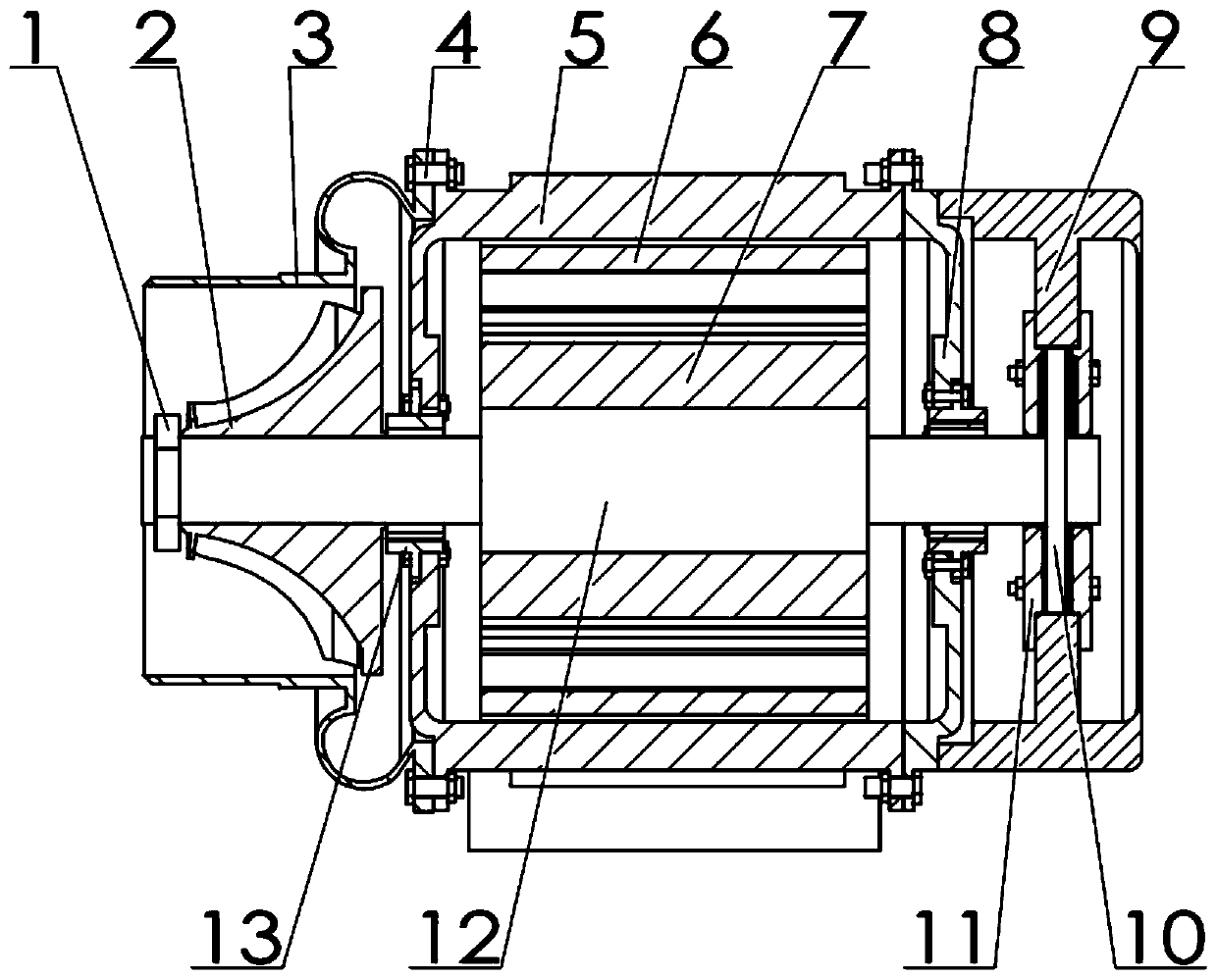

[0026] Such as figure 1 As shown, the centrifugal compressor first includes a shell unit, and the shell includes a compressor housing 5, which is arranged on the surrounding part of the centrifugal compressor for protecting the internal structure of the centrifugal compressor and providing a first tilting pad diameter Installed to the bearing and other parts, the housing can adopt a one-piece structure or a segmented assembly structure, which can be freely arranged by those skilled in the art according to the size of the centrifugal compressor.

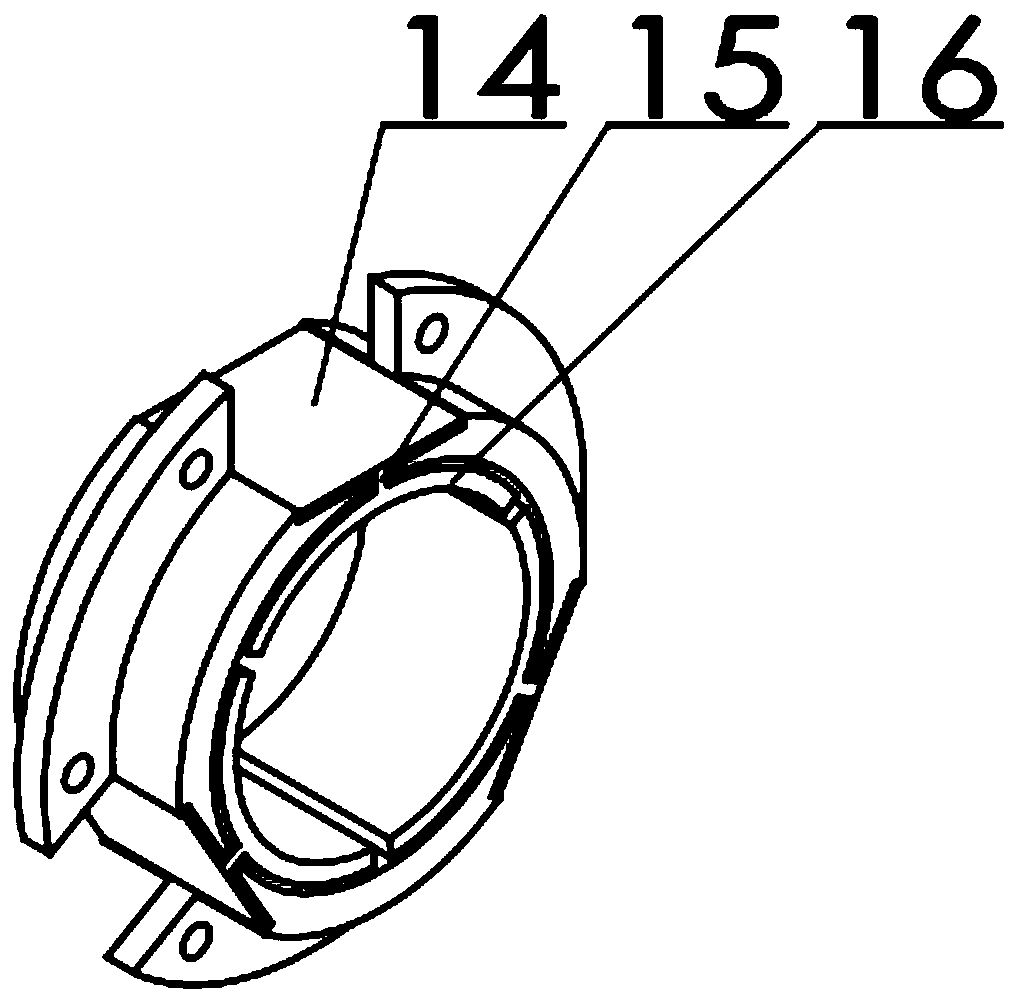

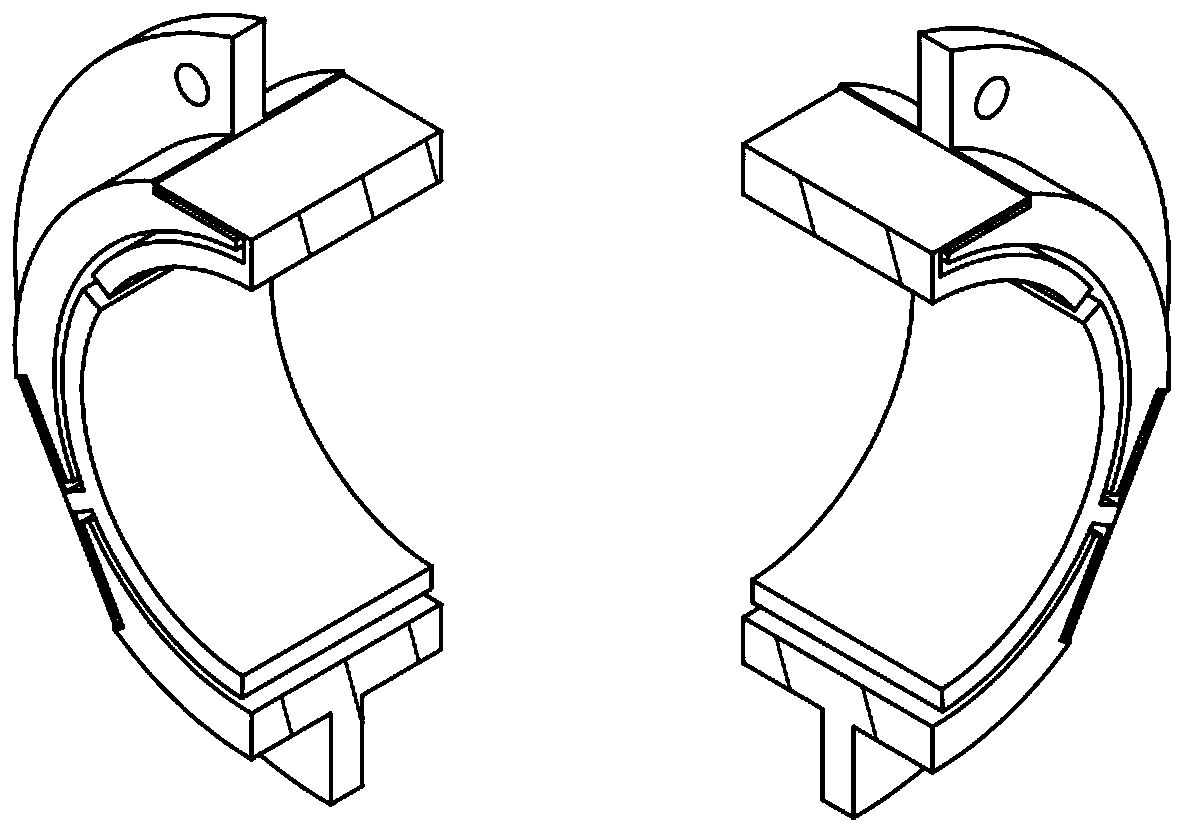

[0027] The shell unit firstly included in the centrifugal compressor also includes a tilting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com