Automobile engine damping device

A technology of automobile engine and shock absorber, which is applied in power units, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of short life and easy damage of the engine, and achieve the effect of high-efficiency shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

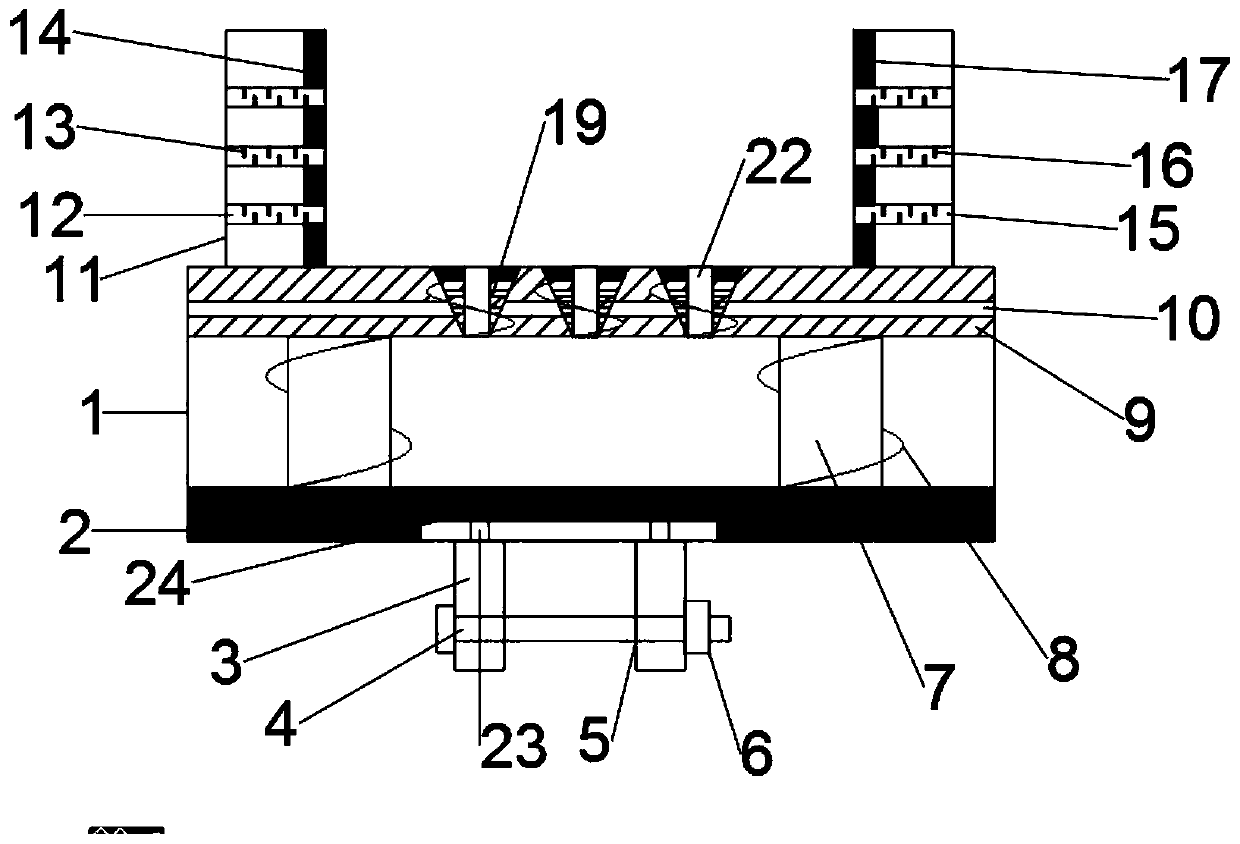

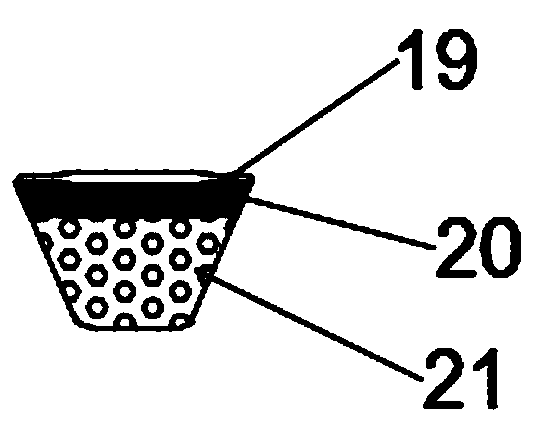

[0022] see figure 1 and image 3 , in an embodiment of the present invention, an automobile engine shock absorber includes a first support body 1, a first buffer layer 2, a splint 3, a second support body 9 and a shock absorbing block 19, and the first support body 1 The bottom is provided with a first cushioning layer 2, which is filled with a foam cushioning material inside the first cushioning layer 2 to play a shock-absorbing effect. The middle part of the first cushioning layer 2 is provided with a groove 24, and the inside of the groove 24 A slide block 23 for sliding connection is provided, and a splint 3 fixedly connected is provided below the slide block 23, and a bolt hole 5 is provided on the splint 3, and the bolt hole 5 is threadedly matched with the bolt 4, and the right end of the bolt 4 is provided with a The nut 6 passes through the bolt hole 5 through the bolt 4, and uses a wrench to tighten the two splints 3, thereby fixing the device on the car.

[0023] ...

Embodiment 2

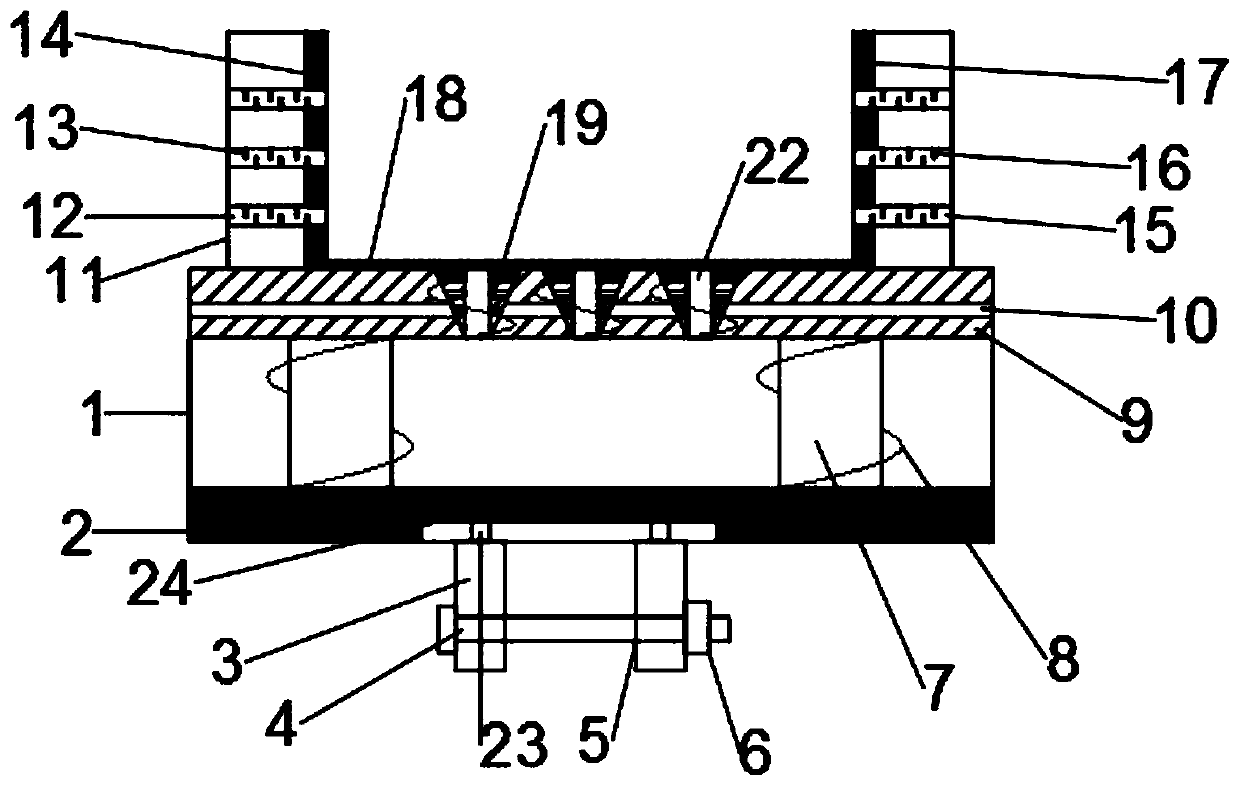

[0029] see figure 2 and 3 , in an embodiment of the present invention, an automobile engine shock absorber includes a first support body 1, a first buffer layer 2, a splint 3, a second support body 9 and a shock absorbing block 19, and the first support body 1 The bottom is provided with a first cushioning layer 2, which is filled with a foam cushioning material inside the first cushioning layer 2 to play a shock-absorbing effect. The middle part of the first cushioning layer 2 is provided with a groove 24, and the inside of the groove 24 A slide block 23 for sliding connection is provided, and a splint 3 fixedly connected is provided below the slide block 23, and a bolt hole 5 is provided on the splint 3, and the bolt hole 5 is threadedly matched with the bolt 4, and the right end of the bolt 4 is provided with a The nut 6 passes through the bolt hole 5 through the bolt 4, and uses a wrench to tighten the two splints 3, thereby fixing the device on the car.

[0030] Furthe...

Embodiment 3

[0037] An automobile engine auxiliary installation device includes the automobile engine shock absorbing device.

[0038] The working principle of the present invention is: the right end of the bolt 4 is provided with a nut 6, the bolt 4 passes through the bolt hole 5, and the two splints 3 are tightened with a wrench, so that the device is fixed on the automobile, the first cushioning layer 2, the elastic The rod 7, the first spring 8, the second support body 9 and the shock absorber 19 play the role of buffer protection, the first air outlet channel 10, the second air outlet channel 22 and the air outlet hole 21 cooperate with each other to play a heat dissipation effect, and the second channel The air holes 15 also play a role in heat dissipation, while the second stoppers 16 are arranged at intervals, which can play the role of noise reduction, and the first rubber pad 14 and the second rubber pad 17 can be compressed, thereby better fixing and protecting different parts. si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com