Lathe base with efficient damping performance

A shock-absorbing performance and lathe technology, which is applied in the field of lathes, can solve problems such as reducing work enthusiasm, dust leakage, and affecting the working environment, and achieve the effects of improving work enthusiasm, efficient shock absorption, and a good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

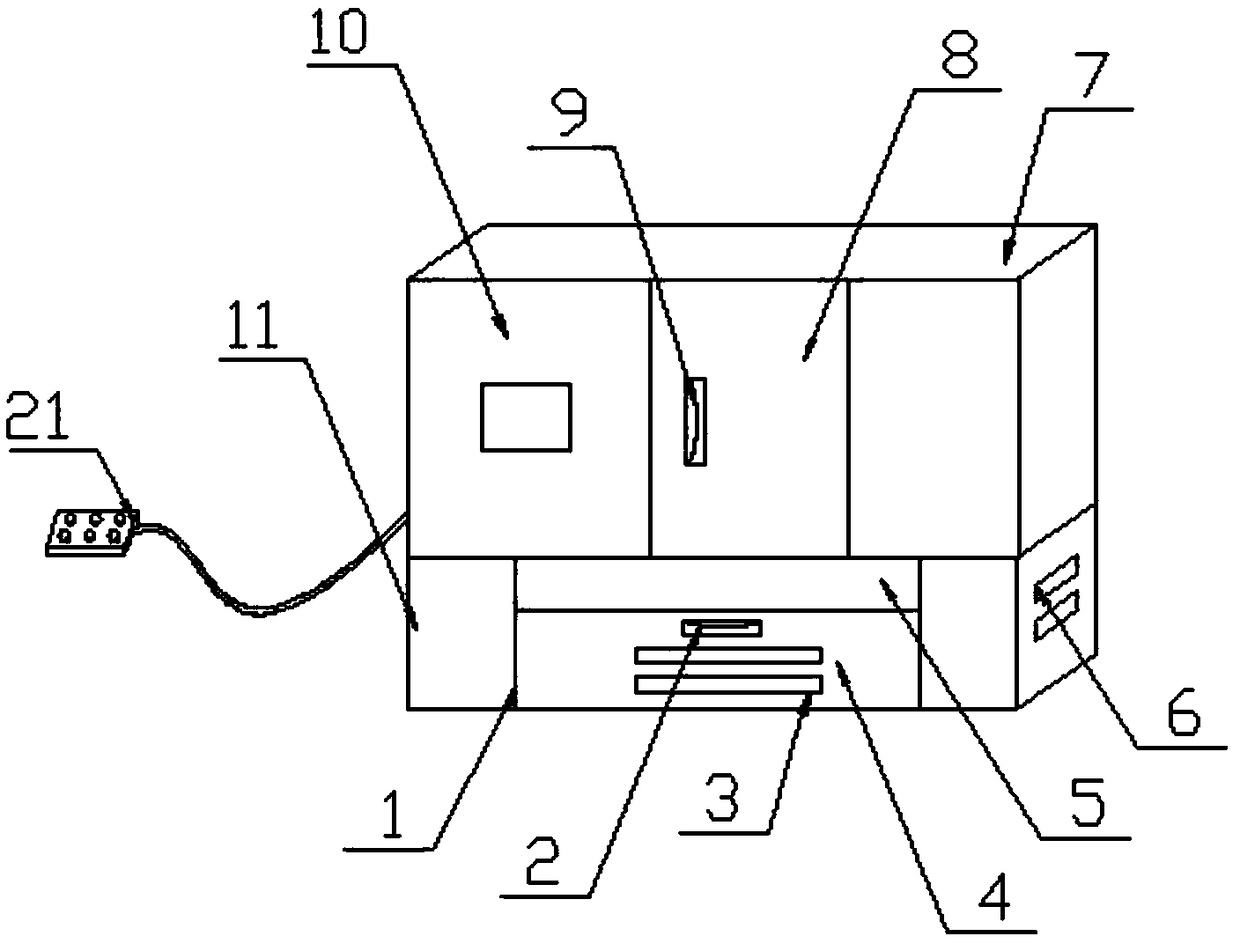

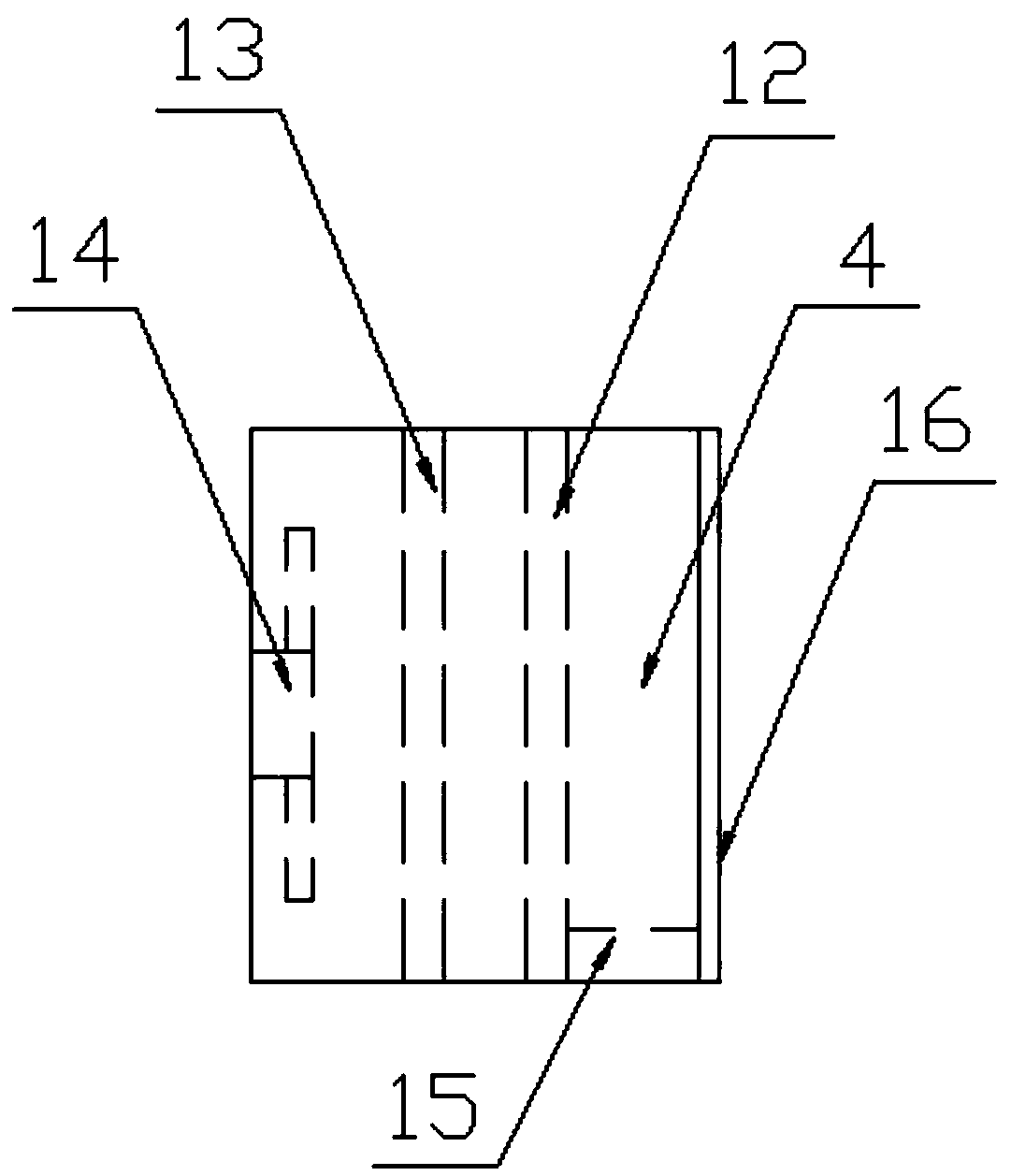

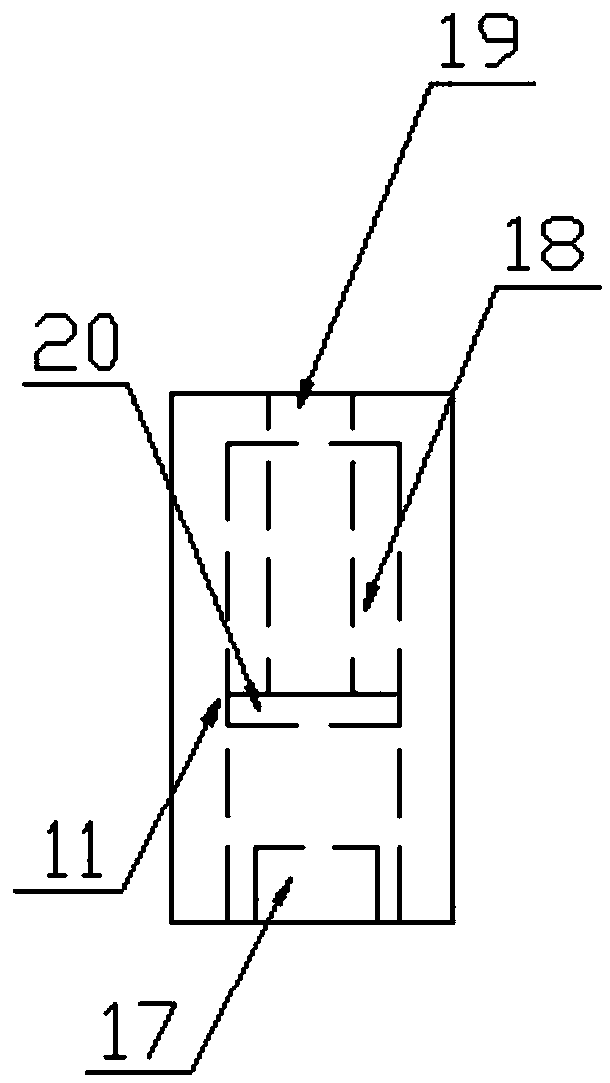

[0017] see Figure 1-3 , the present invention provides a technical solution: a lathe base with high-efficiency shock absorption performance, including a base body 1, a first groove handle 2, an air inlet 3, a purification box 4, a cooling liquid storage box 5, an air outlet 6, Lathe 7, sliding door 8, second groove handle 9, main machine 10, hydraulic shock absorber 11, first filter 12, second filter 13, fan 14, large sundries storage box 15, door 16, electromagnetic Valve 17, hydraulic oil tank 18, piston rod 19, piston head 20 and power control board 21, the top of base body 1 is provided with lathe 7, one side of lathe 7 is provided with main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com