Scanning nondestructive testing system and method based on weak magnetic sensor

A weak magnetic sensor, non-destructive testing technology, applied in the size/direction of the magnetic field, magnetic field measurement using the principle of magnetic flux control, instruments, etc., can solve the problems of inconvenient infrared detection, large thickness of composite materials, etc., to achieve rapid identification and positioning. , to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

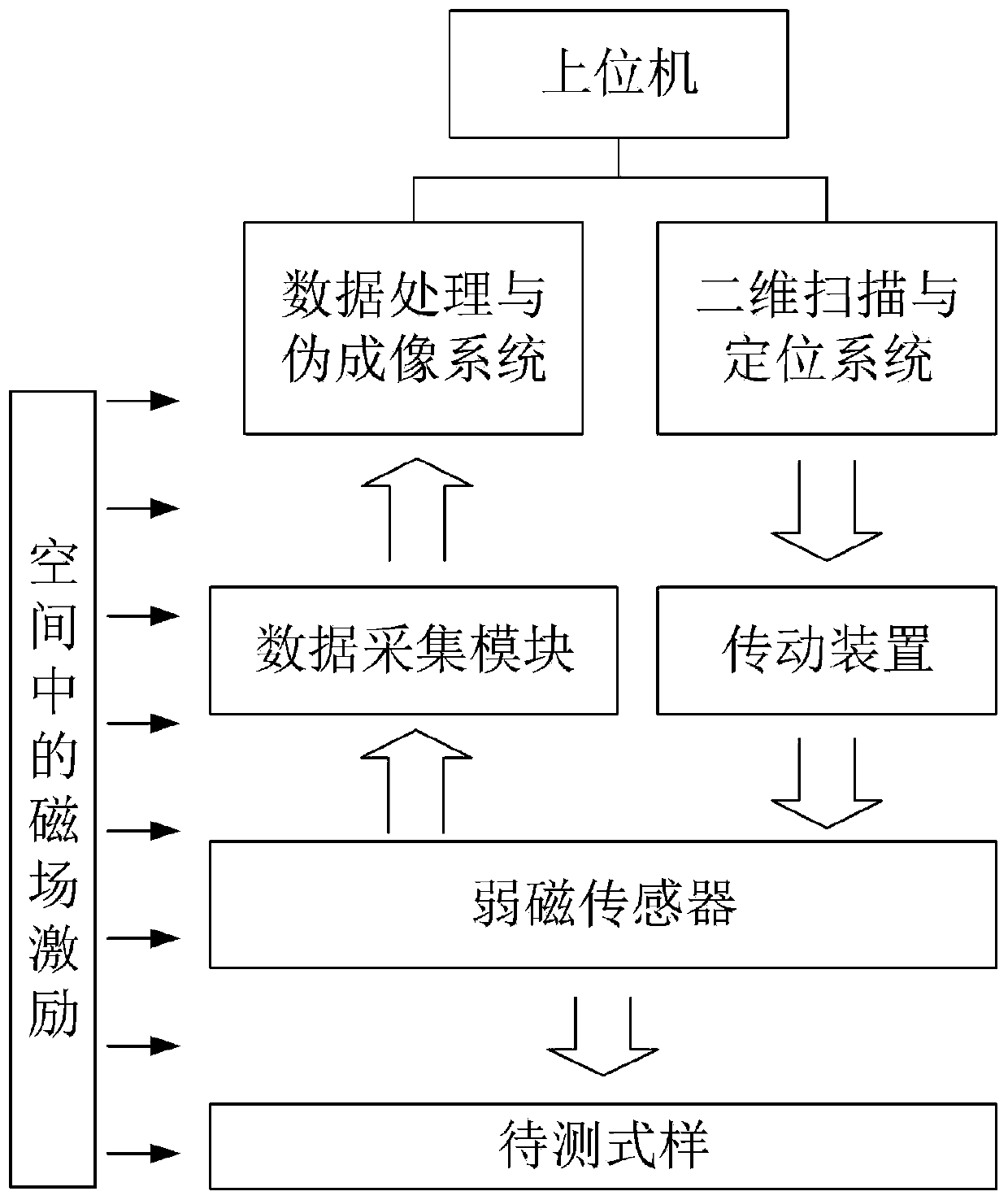

[0015] Specific Embodiment 1: This embodiment describes a scanning non-destructive testing system based on a magnetic field weakening sensor, such as figure 1 As shown, the system includes a host computer, a data acquisition module, a transmission device, and a magnetic field weakening sensor;

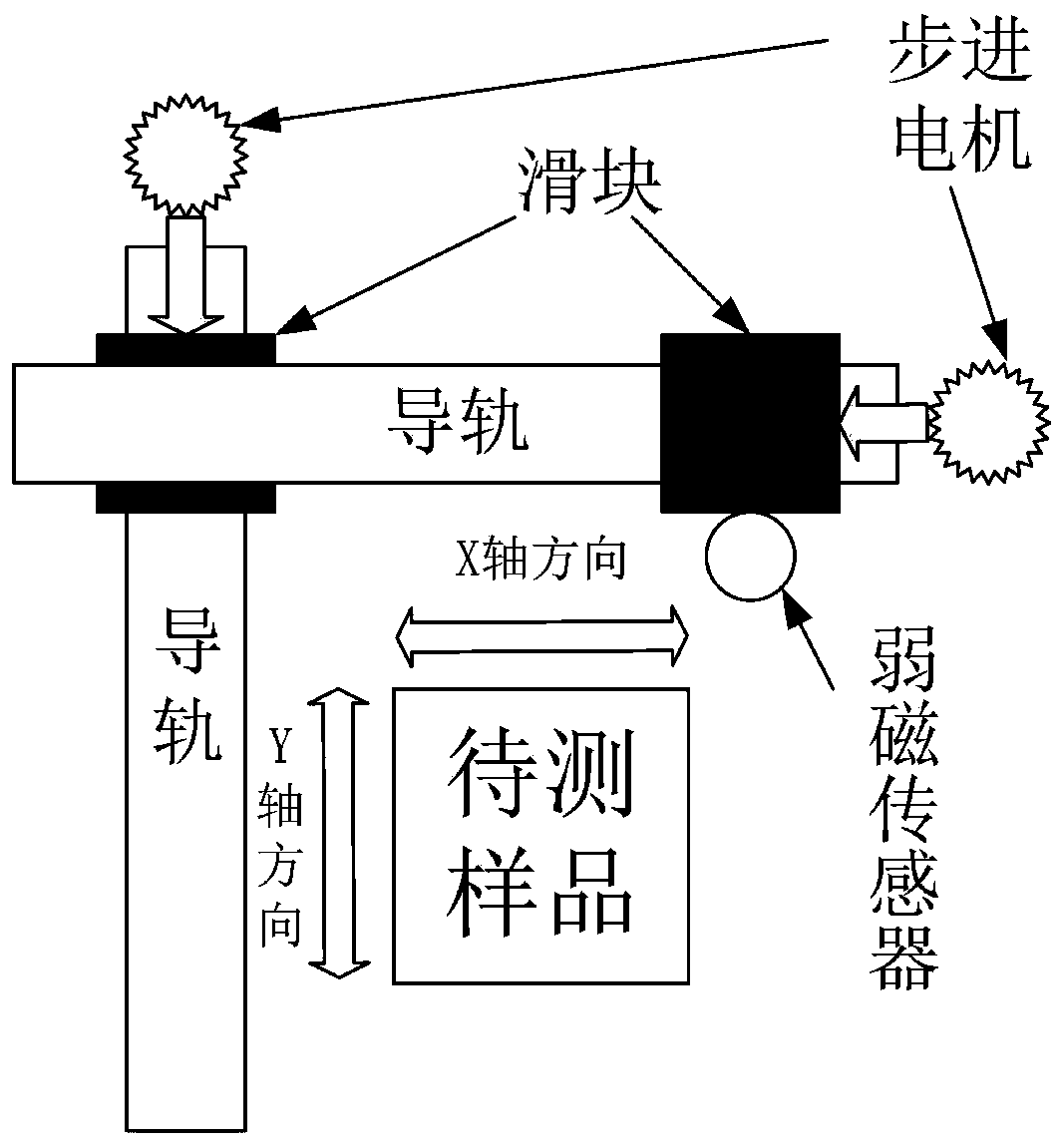

[0016] The host computer includes a data processing and pseudo-imaging system and a two-dimensional scanning and positioning system. The two-dimensional scanning and positioning system controls the weak magnetic sensor to scan the sample to be tested through the transmission device, and the signal of the weak magnetic sensor is transmitted to the data in one direction. The acquisition module, the signal of the data acquisition module is transmitted to the data processing and pseudo-imaging system in one direction. The above-mentioned system is excited by a magnetic field with a fixed frequency of 4 Hz, and the transmission device includes two stepping motors, two sliders and two synchr...

specific Embodiment approach 2

[0017] Specific embodiment two: a method for scanning non-destructive testing using the scanning non-destructive testing system based on the magnetic field weakening sensor described in specific embodiment one, the specific steps of the method are as follows:

[0018] Step 1: Use a 4Hz fixed-frequency magnetic field to excite the test system. This operation can provide a stable magnetic field for the entire test environment and weaken external interference; the magnetic field excitation device can be placed not far from the overall device;

[0019] Step 2: Use two stepping motors to control two sliders to move on the synchronous guide rail to form a transmission device, so that the weak magnetic sensor fixed on the slider can scan the entire sample surface, and use the data acquisition module to scan in real time The measurement data and the position information of the weak magnetic sensor are collected; the fixed weak magnetic sensor is used for scanning detection, which is co...

specific Embodiment approach 3

[0022] Specific embodiment three: the scanning non-destructive testing method based on the scanning non-destructive testing system based on the weak magnetic sensor described in the second specific embodiment, in step 1, the specific magnetic field is formed by the following method: two magnetic induction coils are arranged orthogonally At the same time, 10A alternating current is applied to the two magnetic induction coils, and a sinusoidal magnetic field that is stable in the three axes of X, Y, and Z can be generated in the entire test environment, that is, a magnetic field strength in all directions in a space is generated. The same magnetic field ensures that the total magnetic field strength is stable during the measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com