System for preparing parecoxib freeze-dried powder injection

A technology of freeze-dried powder injection and parecoxib, which is applied in the system field of preparing parecoxib freeze-dried powder injection, can solve the problems of manual operation and increased drying cost, and achieve convenient inflow and outflow and save drying Energy consumption, the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A system for preparing parecoxib freeze-dried powder injection, comprising a cleaning pool, a drying room, a filling line, and a capping device.

[0037] The drying room, filling line, and capping device in this embodiment are all prior art, wherein, the drying room adopts an existing tunnel oven, the filling line adopts an existing powder injection filling machine, and the capping device is an existing In some powder injection bottle capping machines, the connection relationship between the drying chamber, filling line and capping device is also existing, so it will not be described again.

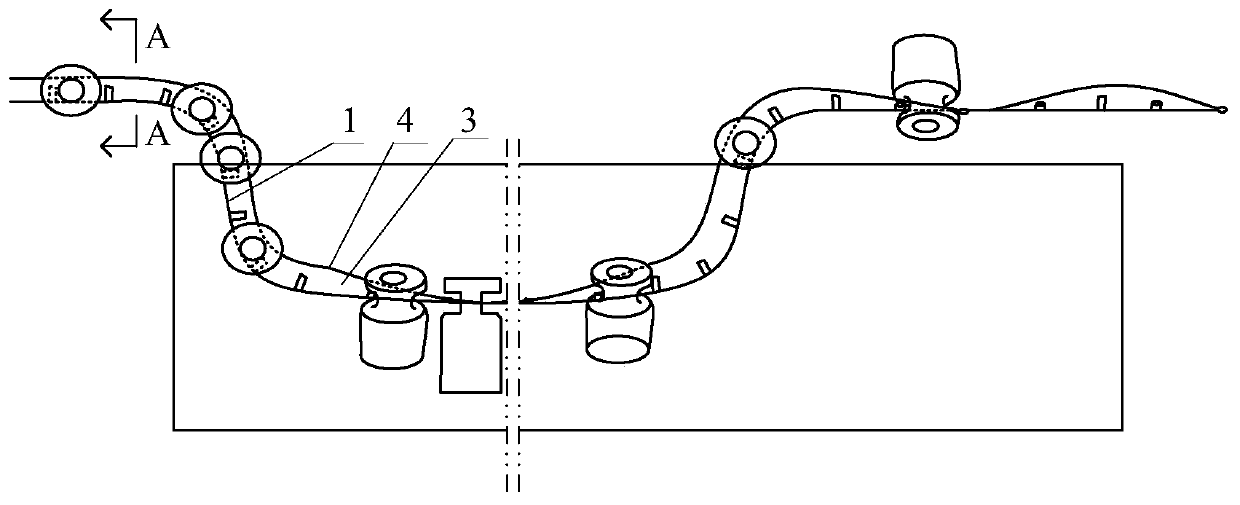

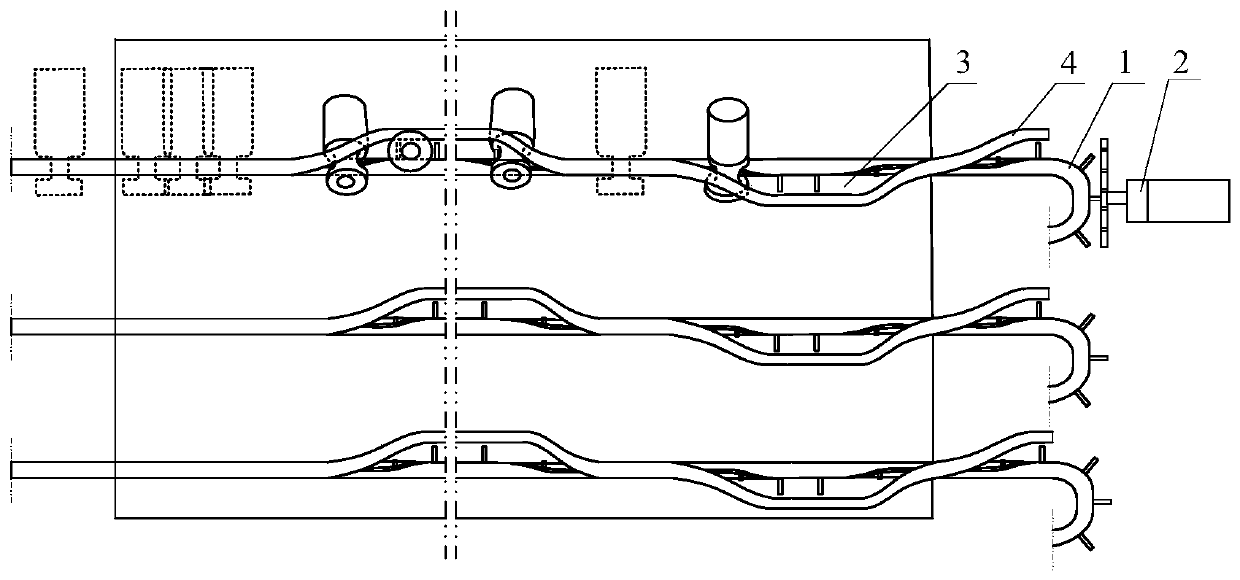

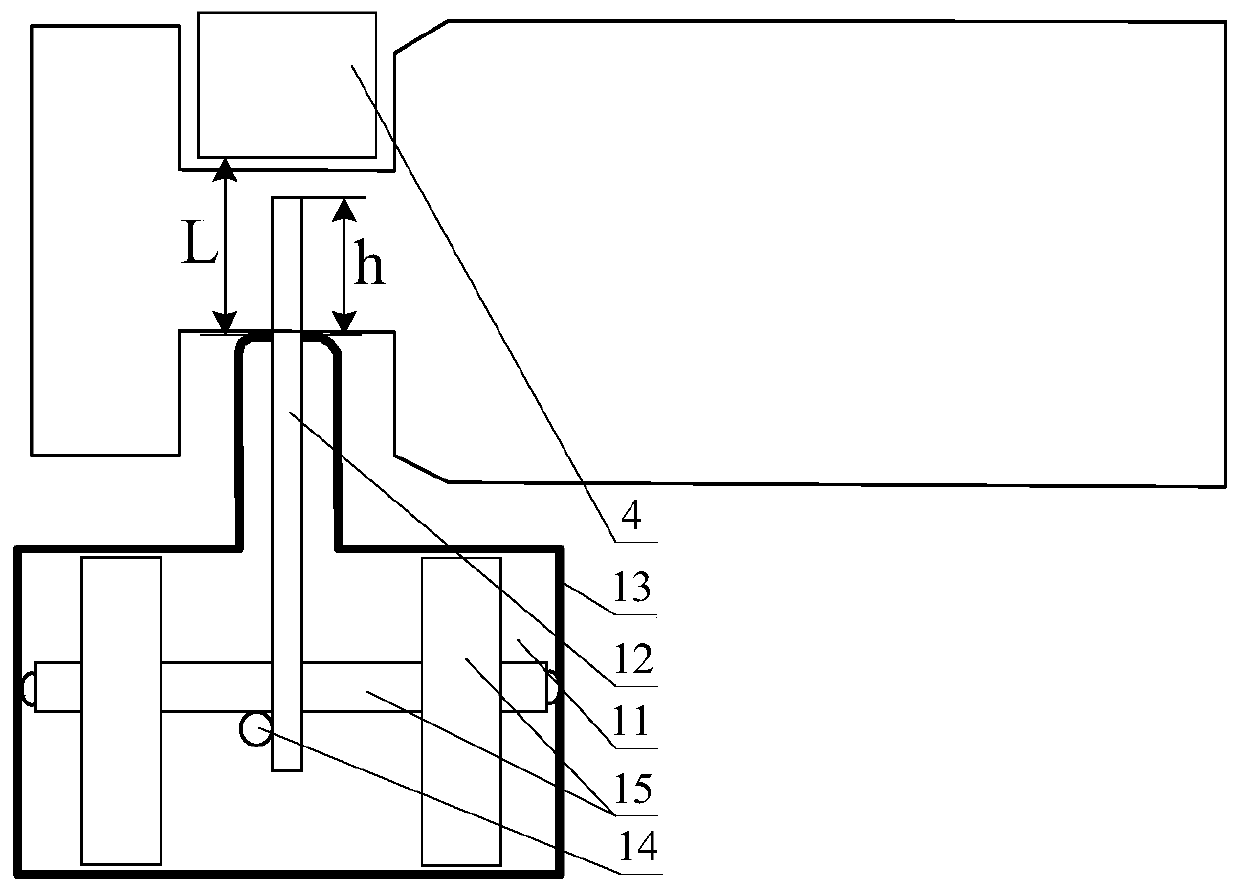

[0038] Such as Figure 1-Figure 3 As shown, a transmission line is also provided in the cleaning tank, and the transmission line includes a transmission belt 1, a driving device 2 for driving the transmission belt 1 to rotate, and is arranged between the top of the transmission belt 1 and the transmission belt 1 to form a bottle mouth channel 3 for vials Restriction 4 of

[0039]...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the structure of the present invention is further optimized in this embodiment, and the specific settings are as follows:

[0052] The length of the rotating segment is greater than 5 cm. The vials transported in the in-plane moving section are arranged parallel to the horizontal plane. The flexible connecting strip 14 is a chain or a nylon rope. The driving device 2 includes a drive gear that drives the flexible connecting strip 14 to move by driving the push rod 12, and a drive motor that drives the drive gear to move; the drive gear includes an endless belt, and the meshing teeth arranged on the inner wall of the endless belt, The driving teeth arranged on the outer wall of the endless belt, and the rotating wheel arranged in the endless belt and meshed with the meshing teeth, the driving motor drives the rotating wheel to rotate and then drives the endless belt to rotate, and the rotation of the endles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com