Air jet cooling device, continuous hot-in and cold-out hot press, and continuous cooling method thereof

A technology of a cooling device and a cooling method, which is applied in veneer presses, plywood presses, and joints of wooden veneers, and can solve problems affecting product quality and production efficiency, difficult evaporation of water, and large heat loss, etc., to achieve The effect of long production cycle, good dimensional stability and large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

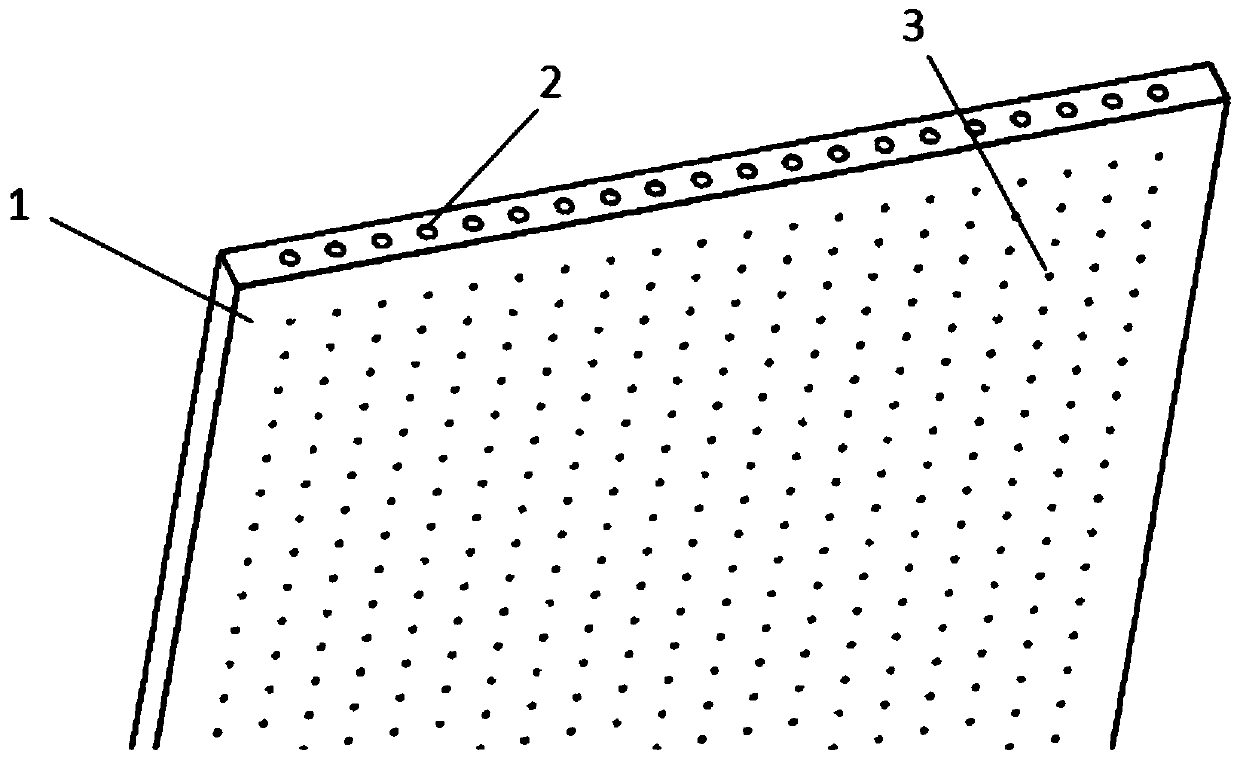

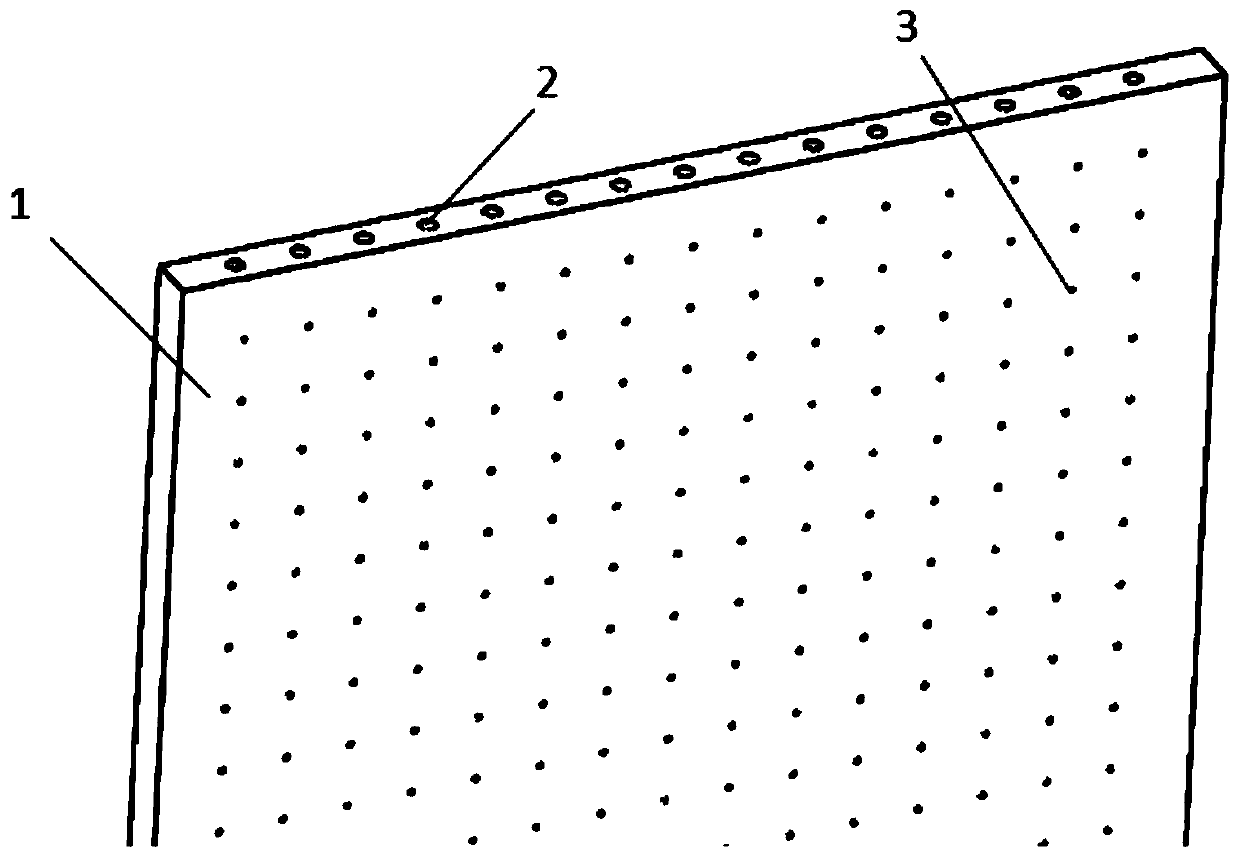

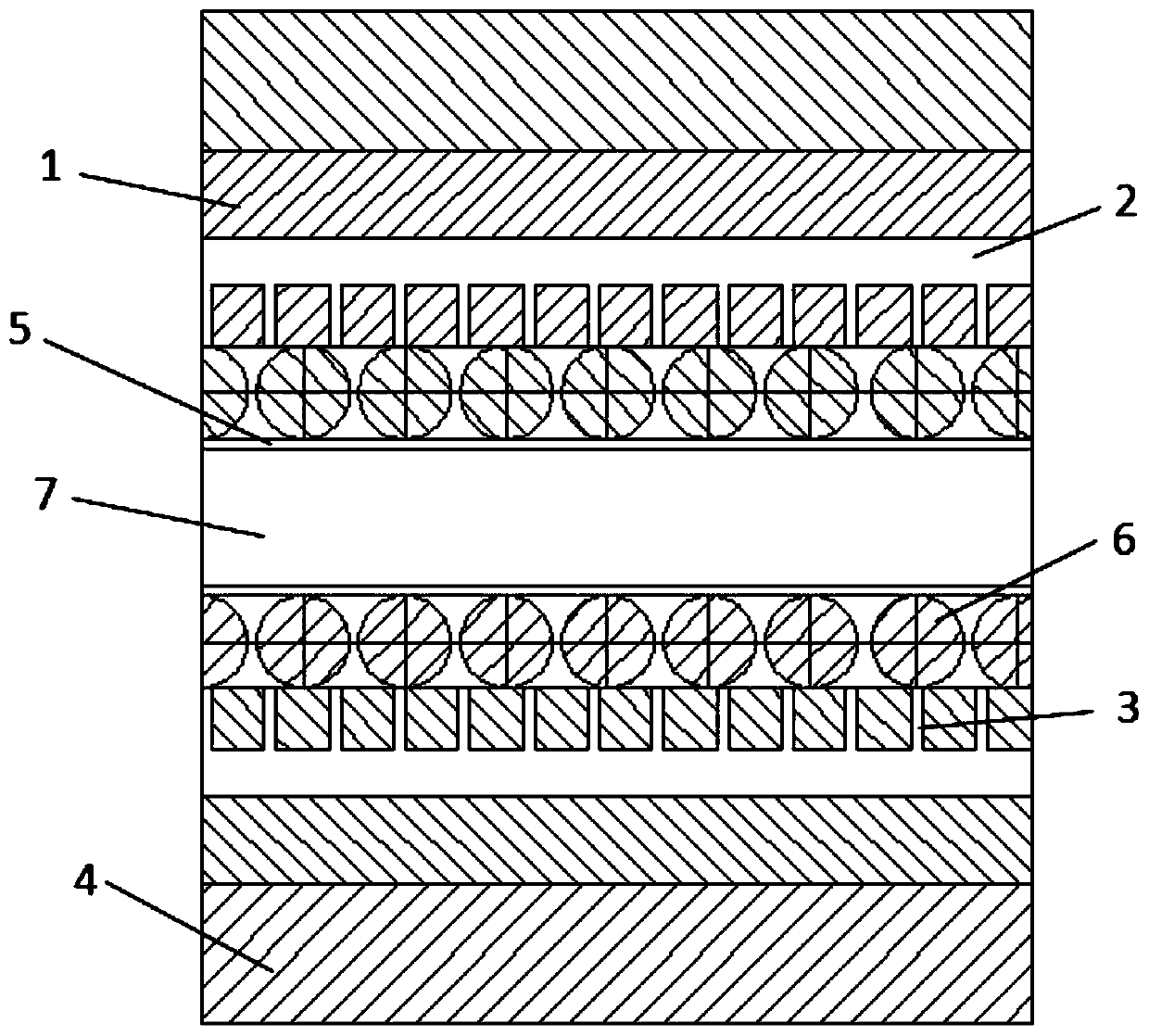

[0025] Such as Figure 1a , Figure 1b , an air jet cooling device, comprising a plurality of cooling platens 1, an air supply pipeline, and a water mist device; several cooling platens are arranged to form an upper and lower two-layer structure, and a plurality of long holes 2 are evenly distributed on the side of the cooling platen 1, and one end of the long holes is closed , the diameter is 8-12mm, and the working surface of the cooling platen is evenly distributed with a number of jet holes 3, and each long hole is connected with a number of jet holes, and the jet holes 3 are vertically connected with the slot holes 2, and the diameter of the jet holes 3 is 1- 3mm, the number of long holes 2 and air jet holes 3 on the cooling platen in the upper and lower two-layer structure decreases from front to back, because the steel belt, roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com